Abstract

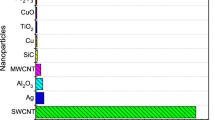

The use of nanofluids in parabolic trough collectors is one of the most promising techniques for enhancing their performance. The objective of this work is to investigate the use of various nanoparticles (Cu, CuO, Fe2O3, TiO2, Al2O3 and SiO2) dispersed in thermal oil (Syltherm 800). A detailed parametric analysis is performed for flow rates from 50 to 300 L min−1, for inlet temperatures from 300 K to 650 K and for nanoparticle concentrations up to 6%, while the impact of the solar irradiation level on the thermal efficiency enhancement is also investigated. Moreover, a new index for the working fluid evaluation in solar collectors is introduced. The analysis is conducted with a developed thermal model in Engineering Equation Solver. According to the final results, the most efficient nanoparticle is the Cu, with CuO, Fe2O3, TiO2, Al2O3 and SiO2 to follow, respectively. It is found that the higher enhancement is observed for lower flow rates, higher inlet temperatures and higher nanoparticle concentrations, while it is approximately constant for the different solar irradiation levels. For the typical operating conditions with 150 L min−1 flow rate and 600 K inlet temperature, the thermal efficiency enhancement is found 0.31, 0.54 and 0.74% for Cu concentrations 2, 4 and 6%, respectively.

Similar content being viewed by others

Abbreviations

- A :

-

Area, m2

- C :

-

Concentration ratio

- c p :

-

Specific heat capacity under constant pressure, J kg−1 K−1

- D :

-

Diameter, m

- F :

-

Focal length, m

- G b :

-

Solar direct beam irradiation, W m−2

- H :

-

Heat transfer coefficient, W m−2 K−1

- h out :

-

Convection coefficient between cover and ambient, W m−2 K−1

- k :

-

Thermal conductivity, W m−1 K−1

- K :

-

Incident angle modifier

- L :

-

Tube length, m

- m :

-

Mass flow rate, kg s−1

- Nu :

-

Nusselt number

- Pr :

-

Prandtl number

- Q :

-

Heat flux, W

- Re :

-

Reynolds number

- T :

-

Temperature, K

- T sky :

-

Sky temperature, K

- U r :

-

Overall heat transfer coefficient, W m−2 K−1

- V :

-

Volumetric flow rate, L min−1

- V wind :

-

Ambient air velocity, m s−1

- W :

-

Width, m

- α :

-

Absorber absorbance

- β :

-

Ratio of the nanolayer thickness to the original particle radius

- γ :

-

Intercept factor

- ε :

-

Emittance

- η opt :

-

Optical efficiency

- η th :

-

Thermal efficiency

- θ :

-

Solar beam incident angle, o

- μ:

-

Dynamic viscosity, Pa s

- ρ :

-

Density, kg m−3

- ρ mir :

-

Mirror reflectance

- τ :

-

Cover transmittance

- φ :

-

Nanoparticle, concentration %

- a:

-

Aperture

- am:

-

Ambient

- bf:

-

Base fluid

- c :

-

Cover

- ci:

-

Inner cover

- co:

-

Outer cover

- fm:

-

Mean fluid

- in:

-

Inlet

- loss:

-

Thermal loss

- nf:

-

Nanofluids

- np:

-

Nanoparticle

- out:

-

Outlet

- r:

-

Receiver

- ri:

-

Inner receiver

- ro:

-

Outer receiver

- s:

-

Solar

- u:

-

Useful

- 0:

-

Reference

- CFD:

-

Computation fluid dynamic

- EES:

-

Engineering equation solver

- PTC:

-

Parabolic trough collector

References

Loni R, Askari Asli-ardeh E, Ghobadian B, Kasaeian AB, Gorjian Sh. Thermodynamic analysis of a solar dish receiver using different nanofluids. Energy. 2017;133:749–60.

Fernandez AG, Galleguillos H, Fuentealba E, Perez FJ. Thermal characterization of HITEC molten salt for energy storage in solar linear concentrated technology. J Therm Anal Calorim. 2015;122(1):3–9.

Mathioulakis E, Papanicolaou E, Belessiotis V. Optical performance and instantaneous efficiency calculation of linear Fresnel solar collectors. Int J Energy Res. 2017. https://doi.org/10.1002/er.3925.

Bellos E, Tzivanidis C, Papadopoulos A. Enhancing the performance of a linear Fresnel reflector using nanofluids and internal finned absorber. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-6989-1.

Fuqiang W, Ziming C, Jianyu T, Yuan Y, Yong S, Linhua L. Progress in concentrated solar power technology with parabolic trough collector system: a comprehensive review. Renew Sustain Energy Rev. 2017;79:1314–28.

Sandeep HM, Arunachala UC. Solar parabolic trough collectors: a review on heat transfer augmentation techniques. Renew Sustain Energy Rev. 2017;69:1218–31.

Huang Z, Li Z-Y, Yu G-L, Tao W-Q. Numerical investigations on fully-developed mixed turbulent convection in dimpled parabolic trough receiver tubes. Appl Therm Eng. 2017;114:1287–99.

Xiangtao G, Fuqiang W, Haiyan W, Jianyu T, Qingzhi L, Huaizhi H. Heat transfer enhancement analysis of tube receiver for parabolic trough solar collector with pin fin arrays inserting. Sol Energy. 2017;144:185–202.

Bellos E, Tzivanidis C, Tsimpoukis D. Multi-criteria evaluation of parabolic trough collector with internally finned absorbers. Appl Energy. 2017;205:540–61.

Mwesigye A, Bello-Ochende T, Meyer JP. Heat transfer and entropy generation in a parabolic trough receiver with wall-detached twisted tape inserts. Int J Therm Sci. 2016;99:238–57.

Choi SU, Eastman J. Enhancing thermal conductivity of fluids with nanoparticles. Lemont: Argonne National Lab; 1995.

Mahian O, Kianifar A, Sahin AZ, Wongwises S. Entropy generation during Al2O3/water nanofluid flow in a solar collector: Effects of tube roughness, nanoparticle size, and different thermophysical models. Int J Heat Mass Transf. 2014;78:64–75.

Allouhi A, Benzakour Amine M, Saidur R, Kousksou T, Jamil A. Energy and exergy analyses of a parabolic trough collector operated with nanofluids for medium and high temperature applications. Energy Convers Manag. 2018;155:201–17.

Basbous N, Taqi M, Janan MA. Thermal performances analysis of a parabolic trough solar collector using different nanofluids. Renew Sustain Energy Conf (IRSEC). 2016. https://doi.org/10.1109/irsec.2016.7984006.

Bellos E, Tzivanidis C, Antonopoulos KA, Gkinis G. Thermal enhancement of solar parabolic trough collectors by using nanofluids and converging-diverging absorber tube. Renew Energy. 2016;94:213–22.

Bellos E, Tzivanidis C. Parametric investigation of nanofluids utilization in parabolic trough collectors. Therm Sci Eng Progr. 2017;2:71–9.

Bellos E, Tzivanidis C. Thermal analysis of parabolic trough collector operating with mono and hybrid nanofluids. Sustain Energy Technol Assess. 2017. https://doi.org/10.1016/j.seta.2017.10.005.

Bellos E, Tzivanidis C, Tsimpoukis D. Thermal, hydraulic and exergetic evaluation of a parabolic trough collector operating with thermal oil and molten salt based nanofluids. Energy Convers Manag. 2018;156:388–402.

Benabderrahmane A, Aminallah M, Laouedj S, Benazza A, Solano JP. Heat transfer enhancement in a parabolic trough solar receiver using longitudinal fins and nanofluids. J Therm Sci. 2016;25:410–7.

Chaudhari KS, Walke PV, Wankhede US, Shelke RS. An Experimental investigation of a nanofluid (al2o3 + H2O) based parabolic trough solar collectors. Br J Appl Sci Technol. 2015;9(6):551–7.

Coccia G, Di Nicola G, Colla L, Fedele L, Scattolini M. Adoption of nanofluids in low-enthalpy parabolic trough solar collectors: numerical simulation of the yearly yield. Energy Convers Manag. 2016;118:306–19.

Ferraro V, Settino J, Cucumo MA, Kaliakatsos D. Parabolic trough system operating with nanofluids: comparison with the conventional working fluids and influence on the system performance. Energy Proc. 2016;101:782–9.

Ghasemi SE, Ranjbar AA. Thermal performance analysis of solar parabolic trough collector using nanofluid as working fluid: a CFD modelling study. J Mol Liq. 2016;222:159–66.

Ghasemi SE, Ranjbar AA. Effect of using nanofluids on efficiency of parabolic trough collectors in solar thermal electric power plants. Int J Hydrogen Energy. 2017;42(34):21626–34.

Kaloudis E, Papanicolaou E, Belessiotis V. Numerical simulations of a parabolic trough solar collector with nanofluid using a two-phase model. Renew Energy. 2016;97:218–29.

Kasaeian A, Daviran S, Danesh Azarian R, Rashidi A. Performance evaluation and nanofluid using capability study of a solar parabolic trough collector. Energy Convers Manag. 2015;89:368–75.

Khakrah H, Shamloo A, Kazemzadeh S. Hannani, Determination of parabolic trough solar collector efficiency using nanofluid: a comprehensive numerical study. ASME J Sol Energy Eng. 2017;139(5):051006.

Mwesigye A, Huan Z, Meyer JP. Thermodynamic optimisation of the performance of a parabolic trough receiver using synthetic oil—Al2O3 nanofluid. Appl Energy. 2015;156:398–412.

Mwesigye A, Huan Z, MeyerJP, Thermal performance of a receiver tube for a high concentration ratio parabolic trough system and potential for improved performance with Syltherm 800-CuO nanofluid. In: Proceedings of the ASME 2015 international mechanical engineering congress and exposition IMECE, 2015 Nov 13–19, 2015, Houston, Texas.

Mwesigye A, Huan Z. Thermodynamic analysis and optimization of fully developed turbulent forced convection in a circular tube with water–Al2O3 nanofluid. Int J Heat Mass Transf. 2015;89:694–706.

Mwesigye A, Huan Z, Meyer JP. Thermal performance and entropy generation analysis of a high concentration ratio parabolic trough solar collector with Cu-Therminol®VP-1 nanofluid. Energy Convers Manag. 2016;120:449–65.

Mwesigye A, Meyer JP. Optimal thermal and thermodynamic performance of a solar parabolic trough receiver with different nanofluids and at different concentration ratios. Appl Energy. 2017;193:393–413.

Mwesigye A, Yılmaz İH, Meyer JP. Numerical analysis of the thermal and thermodynamic performance of a parabolic trough solar collector using SWCNTs-Therminol®VP-1 nanofluid. Renew Energy. 2017. https://doi.org/10.1016/j.renene.2017.10.047.

Rehan MA, Ali M, Sheikh NA, Khalil MS, Chaudhary GQ, ur Rashid T, Shehryar M. Experimental performance analysis of low concentration ratio solar parabolic trough collectors with nanofluids in winter conditions. Renew Energy. 2018;118:742–51.

Sokhansefat T, Kasaeian AB, Kowsary F. Heat transfer enhancement in parabolic trough collector tube using Al2O3/synthetic oil nanofluid. Renew Sustain Energy Rev. 2014;33:636–44.

Subramani J, Nagarajan PK, Wongwises S, El-Agouz SA, Sathyamurthya R. Experimental study on the thermal performance and heat transfer characteristics of solar parabolic trough collector using Al2O3 nanofluids. Environ Progr Sustain Energy. 2017. https://doi.org/10.1002/ep.12767.

Subramani J, Nagarajan PK, Mahian O, Sathyamurthy R. Efficiency and heat transfer improvements in a parabolic trough solar collector using TiO2 nanofluids under turbulent flow regime. Renew Energy. 2018;119:19–31.

Wang Y, Xu J, Liu Q, Chen Y, Liu H. Performance analysis of a parabolic trough solar collector using Al2O3/synthetic oil nanofluid. Appl Therm Eng. 2016;107:469–78.

Zadeh PM, Sokhansefat T, Kasaeian AB, Kowsary F, Akbarzadeh A. Hybrid optimization algorithm for thermal analysis in a solar parabolic trough collector based on nanofluid. Energy. 2015;82:857–64.

Bellos E, Tzivanidis C. Assessment of the thermal enhancement methods in parabolic trough collectors. Int J Energy Environ Eng. 2017. https://doi.org/10.1007/s40095-017-0255-3.

Behar O, Khellaf A, Mohammedi K. A novel parabolic trough solar collector model—Validation with experimental data and comparison to Engineering Equation Solver (EES). Energy Convers Manag. 2015;106:268–81.

Forristall R. Heat transfer analysis and modeling of a parabolic trough solar receiver implemented in engineering equation solver. Colorado: National Renewable Energy Laboratory–NREL; 2003.

Bellos E, Tzivanidis C, Antonopoulos KA, Daniil I. The use of gas working fluids in parabolic trough collectors—an energetic and exergetic analysis. Appl Therm Eng. 2016;109(A):1–14.

Bellos E, Tzivanidis C, Antonopoulos KA. A detailed working fluid investigation for solar parabolic trough collectors. Appl Therm Eng. 2017;114:374–86.

Bellos E, Tzivanidis C. A detailed exergetic analysis of parabolic trough collectors. Energy Convers Manag. 2017;149:275–92.

F-Chart software, engineering equation solver (EES), 2015. http://www.fchart.com/ees.

Swinbank WC. Long-wave radiation from clear skies. QJR Meteorol Soc. 1963;89:339–40.

Qiu Y, Li M-J, He Y-L, Tao W-Q. Thermal performance analysis of a parabolic trough solar collector using supercritical CO2 as heat transfer fluid under non-uniform solar flux. Appl Therm Eng. 2017;115:1255–65.

Leinhard J IV, Leinhard V. A heat transfer textbook. 4th ed. Cambridge: Philogiston Press; 2012.

http://www.loikitsdistribution.com/files/syltherm-800-technical-data-sheet.pdf.

Khanafer K, Vafai K. A critical synthesis of thermophysical characteristics of nanofluids. Int J Heat Mass Transf. 2011;54(19):4410–28.

Yu W, Choi SUS. The role of interfacial layers in the enhanced thermal conductivity of nanofluids: a renovated Maxwell model. J Nanopart Res. 2003;5:167.

Duangthongsuk W, Wongwises S. An experimental study on the heat transfer performance and pressure drop of TiO2—water nanofluids flowing under a turbulent flow regime. Int J Heat Mass Transf. 2010;53(1–3):334–44.

Batchelor GK. The effect of Brownian motion on the bulk stress in a suspension of spherical particles. J Fluid Mech. 1977;83:97–117.

Acknowledgements

Dr. Evangelos Bellos would like to thank “Bodossaki Foundation” for its financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bellos, E., Tzivanidis, C. Thermal efficiency enhancement of nanofluid-based parabolic trough collectors. J Therm Anal Calorim 135, 597–608 (2019). https://doi.org/10.1007/s10973-018-7056-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7056-7