Abstract

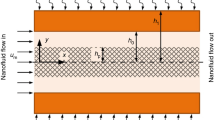

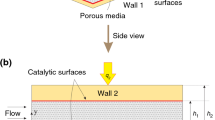

Understanding transport phenomena in microreactors remains challenging owing to the peculiar transfer features of microstructure devices and their interactions with chemistry. This paper, therefore, theoretically investigates heat and mass transfer in microreactors consisting of porous microchannels with thick walls, typical of real microreactors. To analyse the porous section of the microchannel, the local thermal non-equilibrium model of thermal transport in porous media is employed. A first-order, catalytic chemical reaction is implemented on the internal walls of the microchannel to establish the mass transfer boundary conditions. The effects of thermal radiation and nanofluid flow within the microreactor are then included within the governing equations. Further, the species concentration fields are coupled with that of the nanofluid temperature through considering the Soret effect. A semi-analytical methodology is used to tackle the resultant mathematical model with two different thermal boundary conditions. Temperature and species concentration fields as well as Nusselt number for the hot wall are reported versus various parameters such as porosity, radiation parameter and volumetric concentration of nanoparticles. The results show that radiative heat transfer imparts noticeable effects upon the temperature fields and consequently Nusselt number of the system. Importantly, it is observed that the radiation effects can lead to the development of a bifurcation in the nanofluid and porous solid phases and significantly influence the concentration field. This highlights the importance of including thermal radiation in thermochemical simulations of microreactors.

Similar content being viewed by others

Abbreviations

- \(a_{\text{sf}}\) :

-

Interfacial area per unit volume of porous media, m−1

- \(Bi\) :

-

Biot number

- \(c\) :

-

Concentration of the chemical products per unit volume, \({\text{mol}}\,{\text{m}}^{ - 3}\)

- \(c_{\text{p,nf}}\) :

-

Specific heat of the fluid phase of the porous medium, \({\text{J}}\,{\text{kg}}^{ - 1} \,{\text{K}}^{ - 1}\)

- \(D\) :

-

Diffusion coefficient, \({\text{m}}^{2} \,{\text{s}}^{ - 1}\)

- \(Da\) :

-

Darcy number

- \(D_{\text{T}}\) :

-

Thermodiffusion coefficient, \({\text{m}}^{2} \,{\text{s}}^{ - 1} \,{\text{K}}^{ - 1}\)

- h 1 :

-

Height of the lower wall, m

- h 2 :

-

Height of the lower boundary of the upper wall, m

- h 3 :

-

Height of the upper boundary of the upper wall, m

- h :

-

External heat convection coefficient, \({\text{W}}\,{\text{m}}^{ - 2} \,{\text{K}}^{ - 1}\)

- h sf :

-

Internal heat convection coefficient, \({\text{W}}\,{\text{m}}^{ - 2} \,{\text{K}}^{ - 1}\)

- k :

-

Solid-to-fluid effective thermal conductivity ratio

- k 1 :

-

Reference thermal conductivity for lower solid material, \({\text{W}}\,{\text{m}}^{ - 1} \,{\text{K}}^{ - 1}\)

- k 2 :

-

Reference thermal conductivity for upper solid material, \({\text{W}}\,{\text{m}}^{ - 1} \,{\text{K}}^{ - 1}\)

- k e1 :

-

Ratio of the fluid to lower solid material thermal conductivities

- k e2 :

-

Ratio of the fluid to upper solid material thermal conductivities

- k e,nf :

-

Effective thermal conductivity of the nanofluid phase of the porous medium, \({\text{W}}\,{\text{m}}^{ - 1} \,{\text{K}}^{ - 1}\)

- k es :

-

Effective thermal conductivity of the solid phase of the porous medium, \({\text{W}}\,{\text{m}}^{ - 1} \,{\text{K}}^{ - 1}\)

- k f :

-

Thermal conductivity of the base fluid, \({\text{W}}\,{\text{m}}^{ - 1} \,{\text{K}}^{ - 1}\)

- k nf :

-

Thermal conductivity of the nanofluid, \({\text{W}}\,{\text{m}}^{ - 1} \,{\text{K}}^{ - 1}\)

- k p :

-

Thermal conductivity of the nanoparticles, \({\text{W}}\,{\text{m}}^{ - 1} \,{\text{K}}^{ - 1}\)

- k R :

-

Kinetic constant, \({\text{m}}\,{\text{s}}^{ - 1}\)

- k s :

-

Thermal conductivity of the solid phase of the porous medium, \({\text{W}}\,{\text{m}}^{ - 1} \,{\text{K}}^{ - 1}\)

- N c :

-

Dimensionless convection heat transfer (Case 2)

- Nu :

-

Nusselt number

- p :

-

Pressure, Pa

- \(Q_{1}\) :

-

Dimensionless volumetric internal heat generation rate for the lower solid material

- \(Q_{2}\) :

-

Dimensionless volumetric internal heat generation rate for the upper solid material

- \(Q_{\text{H}}\) :

-

Dimensionless heat flux boundary condition (Case 2)

- \(\dot{q}_{1}\) :

-

Volumetric internal heat generation rate for the lower solid material, \({\text{W}}\,{\text{m}}^{ - 3}\)

- \(\dot{q}_{2}\) :

-

Volumetric internal heat generation rate for the upper solid material, \({\text{W}}\,{\text{m}}^{ - 3}\)

- \(q_{\text{H}}\) :

-

Heat flux boundary condition (Case 2), \({\text{W}}\,{\text{m}}^{ - 2}\)

- \(q_{\text{r}}\) :

-

Radiation heat flux, \({\text{W}}\,{\text{m}}^{ - 2}\)

- Rd :

-

Dimensionless radiation parameter

- \(S_{\text{s}}\) :

-

Volumetric internal heat generation rate for the solid phase of the porous medium, \({\text{W}}\,{\text{m}}^{ - 3}\)

- \(S_{\text{nf}}\) :

-

Volumetric internal heat generation rate for the fluid phase of the porous medium, \({\text{W}}\,{\text{m}}^{ - 3}\)

- Sr :

-

Soret number

- \(T\) :

-

Temperature, K

- \(T_{1}\) :

-

Temperature of the lower solid material, K

- \(T_{2}\) :

-

Temperature of the upper solid material, K

- \(T_{\text{c}}\) :

-

Outer temperature of the upper solid material, K

- \(T_{\text{H}}\) :

-

Outer temperature of the lower solid material, K

- \(T_{\text{nf}}\) :

-

Temperature of the fluid phase of the porous medium, K

- \(T_{\text{s}}\) :

-

Temperature of the solid phase of the porous medium, K

- U m :

-

Average dimensionless velocity

- \(u_{\text{p}}\) :

-

Velocity of the fluid in porous medium, m s−1

- \(U_{\text{p}}\) :

-

Dimensionless velocity

- Y 1 :

-

Dimensionless height of the lower wall

- Y 2 :

-

Dimensionless height of the upper wall lower boundary

- \(\gamma\) :

-

Damköhler number

- ε :

-

Porosity

- θ :

-

Dimensionless temperature

- θ 1 :

-

Dimensionless temperature of the lower solid material

- θ 2 :

-

Dimensionless temperature of the upper solid material

- θ nf :

-

Dimensionless temperature of the fluid phase of the porous medium

- \(\theta_{\text{nf,m}}\) :

-

Dimensionless average temperature of the fluid phase of the porous medium

- \(\theta_{\text{s}}\) :

-

Dimensionless temperature of the solid phase of the porous medium

- \(\theta_{\text{H}}\) :

-

Dimensionless temperature at outer side of the lower wall

- \(\kappa\) :

-

Permeability, \({\text{m}}^{2}\)

- \(\kappa^{*}\) :

-

Rosseland mean absorption coefficient

- \(\mu_{\text{eff}}\) :

-

Dynamic viscosity of porous medium, \({\text{Kg}}\,{\text{s}}^{ - 1} \,{\text{m}}^{ - 1}\)

- \(\mu_{\text{f}}\) :

-

Dynamic viscosity of the se fluid, \({\text{Kg}}\,{\text{s}}^{ - 1} \,{\text{m}}^{ - 1}\)

- \(\mu_{\text{nf}}\) :

-

Dynamic viscosity of the nanofluid, \({\text{Kg}}\,{\text{s}}^{ - 1} \,{\text{m}}^{ - 1}\)

- \(\omega_{\text{s}}\) :

-

Dimensionless volumetric internal heat generation rate for the solid phase of the porous medium

- \(\omega_{\text{nf}}\) :

-

Dimensionless volumetric internal heat generation rate for the fluid phase of the porous medium

- \(\rho\) :

-

Density of the fluid phase, \({\text{kg}}\,{\text{m}}^{ - 3}\)

- \(\sigma^{*}\) :

-

Stefan–Boltzmann constant, \({\text{W}}\,{\text{m}}^{ - 2} \,{\text{K}}^{ - 4}\)

- \(\phi\) :

-

Dimensionless concentration

References

Walther DC, Ahn J. Advances and challenges in the development of power-generation systems at small scales. Prog Energy Combust Sci. 2011;37:583–610. https://doi.org/10.1016/j.pecs.2010.12.002.

Dincer I, Rosen MA. Thermal energy storage, systems and applications. 2nd ed. Hoboken: Wiley; 2011.

Roberge DM, Ducry L, Bieler N, Cretton P, Zimmermann B. Microreactor technology: a revolution for the fine chemical and pharmaceutical industries? Chem Eng Technol. 2005;28:318–23. https://doi.org/10.1002/ceat.200407128.

Haber J, Kashid MN, Borhani N, Thome J, Krtschil U, Renken A, et al. Infrared imaging of temperature profiles in microreactors for fast and exothermic reactions. Chem Eng J. 2013;214:97–105. https://doi.org/10.1016/j.cej.2012.10.021.

Yao X, Zhang Y, Du L, Liu J, Yao J. Review of the applications of microreactors. Renew Sustain Energy Rev. 2015;47:519–39. https://doi.org/10.1016/j.rser.2015.03.078.

Kolb G. Review: microstructured reactors for distributed and renewable production of fuels and electrical energy. Chem Eng Process Process Intensif. 2013;65:1–44. https://doi.org/10.1016/j.cep.2012.10.015.

Albani D, Vilé G, Beltran Toro MA, Kaufmann R, Mitchell S, Pérez-Ramírez J. Structuring hybrid palladium nanoparticles in metallic monolithic reactors for continuous-flow three-phase alkyne hydrogenation. React Chem Eng. 2016;1:454–62. https://doi.org/10.1039/C6RE00114A.

Kolb G, Hessel V. Micro-structured reactors for gas phase reactions. Chem Eng J. 2004;98:1–38. https://doi.org/10.1016/j.cej.2003.10.005.

Chou SK, Yang WM, Li J, Li ZW. Porous media combustion for micro thermophotovoltaic system applications. Appl Energy. 2010;87:2862–7. https://doi.org/10.1016/j.apenergy.2009.06.039.

Torabi M, Karimi N, Peterson GP, Yee S. Challenges and progress on the modeling of entropy generation in porous media: a review. Int J Heat Mass Transf. 2017;114:31–46. https://doi.org/10.1016/j.ijheatmasstransfer.2017.06.021.

Tanimu A, Jaenicke S, Alhooshani K. Heterogeneous catalysis in continuous flow microreactors: a review of methods and applications. Chem Eng J. 2017;327:792–821. https://doi.org/10.1016/j.cej.2017.06.161.

Guettel R, Turek T. Assessment of micro-structured fixed-bed reactors for highly exothermic gas-phase reactions. Chem Eng Sci. 2010;65:1644–54. https://doi.org/10.1016/j.ces.2009.11.002.

Ju Y, Maruta K. Microscale combustion: technology development and fundamental research. Prog Energy Combust Sci. 2011;37:669–715. https://doi.org/10.1016/j.pecs.2011.03.001.

Torabi M, Torabi M, Peterson GP. Entropy generation of double diffusive forced convection in porous channels with thick walls and Soret effect. Entropy. 2017;19:171. https://doi.org/10.3390/e19040171.

Hunt G, Karimi N, Torabi M. Analytical investigation of heat transfer and classical entropy generation in microreactors—the influences of exothermicity and asymmetry. Appl Therm Eng. 2017;119:403–24. https://doi.org/10.1016/j.applthermaleng.2017.03.057.

Elliott A, Torabi M, Karimi N. Thermodynamics analyses of porous microchannels with asymmetric thick walls and exothermicity: an entropic model of microreactors. J Therm Sci Eng Appl. 2017;9:41013. https://doi.org/10.1115/1.4036802.

Dickson C, Torabi M, Karimi N. First and second law analyses of nanofluid forced convection in a partially-filled porous channel—the effects of local thermal non-equilibrium and internal heat sources. Appl Therm Eng. 2016;103:459–80. https://doi.org/10.1016/j.applthermaleng.2016.04.095.

Torabi M, Zhang K. Temperature distribution, local and total entropy generation analyses in MHD porous channels with thick walls. Energy. 2015;87:540–54. https://doi.org/10.1016/j.energy.2015.05.009.

Hunt G, Karimi N, Torabi M. Two-dimensional analytical investigation of coupled heat and mass transfer and entropy generation in a porous, catalytic microreactor. Int J Heat Mass Transf. 2018;119:372–91. https://doi.org/10.1016/j.ijheatmasstransfer.2017.11.118.

Elliott A, Torabi M, Karimi N, Cunningham S. On the effects of internal heat sources upon forced convection in porous channels with asymmetric thick walls. Int Commun Heat Mass Transf. 2016;73:100–10. https://doi.org/10.1016/j.icheatmasstransfer.2016.02.016.

Elliott A, Torabi M, Hunt G, Karimi N. Erratum to “On the effects of internal heat sources upon forced convection in porous channels with asymmetric thick walls” [Int. Comm. Heat Mass Trans. 73 (2016) 100–110]. Int Commun Heat Mass Transf. 2017;2017(85):76–80. https://doi.org/10.1016/j.icheatmasstransfer.2017.05.002.

Torabi M, Zhang K. First and second thermodynamic laws analyses between and inside two rotating solid cylindrical geometries with magnetohydrodynamic flow. Int J Heat Mass Transf. 2015;89:760–9. https://doi.org/10.1016/j.ijheatmasstransfer.2015.05.101.

Torabi M, Zhang K, Shohel M. Temperature and entropy generation analyses between and inside two rotating solid cylindrical geometries using copper-water nanofluid. J Heat Transf. 2015;137:51701. https://doi.org/10.1115/1.4029596.

Li YF, Xia GD, Ma DD, Jia YT, Wang J. Characteristics of laminar flow and heat transfer in microchannel heat sink with triangular cavities and rectangular ribs. Int J Heat Mass Transf. 2016;98:17–28. https://doi.org/10.1016/j.ijheatmasstransfer.2016.03.022.

Zhai YL, Xia GD, Liu XF, Li YF. Exergy analysis and performance evaluation of flow and heat transfer in different micro heat sinks with complex structure. Int J Heat Mass Transf. 2015;84:293–303. https://doi.org/10.1016/j.ijheatmasstransfer.2015.01.039.

Torabi M, Zhang K, Karimi N, Peterson GP. Entropy generation in thermal systems with solid structures—a concise review. Int J Heat Mass Transf. 2016;97:917–31. https://doi.org/10.1016/j.ijheatmasstransfer.2016.03.007.

Serrano-Arellano J, Gijón-Rivera M, Riesco-Ávila JM, Elizalde-Blancas F. Numerical study of the double diffusive convection phenomena in a closed cavity with internal CO2 point sources. Int J Heat Mass Transf. 2014;71:664–74. https://doi.org/10.1016/j.ijheatmasstransfer.2013.12.078.

Kefayati GR. Simulation of double diffusive natural convection and entropy generation of power-law fluids in an inclined porous cavity with Soret and Dufour effects (part I: study of fluid flow, heat and mass transfer). Int J Heat Mass Transf. 2016;94:539–81. https://doi.org/10.1016/j.ijheatmasstransfer.2015.05.058.

Sahu KC. Double diffusive effects on pressure-driven miscible channel flow: influence of variable diffusivity. Int J Multiph Flow. 2013;55:24–31. https://doi.org/10.1016/j.ijmultiphaseflow.2013.03.005.

Bhagat KD, Tripathi MK, Sahu KC. Instability due to double-diffusive phenomenon in pressure-driven displacement flow of one fluid by another in an axisymmetric pipe. Eur J Mech B Fluids. 2016;55:63–70. https://doi.org/10.1016/j.euromechflu.2015.08.006.

Torabi M, Karimi N, Zhang K. Heat transfer and second law analyses of forced convection in a channel partially filled by porous media and featuring internal heat sources. Energy. 2015;93:106–27. https://doi.org/10.1016/j.energy.2015.09.010.

Chen WH, Cheng TC, Hung CI. Modeling and simulation of microwave double absorption on methanol steam reforming for hydrogen production. Int J Hydrog Energy. 2011;36:333–44. https://doi.org/10.1016/j.ijhydene.2010.09.009.

Chen WH, Cheng TC, Hung CI. Numerical predictions on thermal characteristic and performance of methanol steam reforming with microwave-assisted heating. Int J Hydrog Energy. 2011;36:8279–91. https://doi.org/10.1016/j.ijhydene.2011.04.145.

Civan F. Porous media transport phenomena. Hoboken: Wiley; 2011.

Torabi M, Peterson GP, Torabi M, Karimi N. A thermodynamic analysis of forced convection through porous media using pore scale modeling. Int J Heat Mass Transf. 2016;99:303–16. https://doi.org/10.1016/j.ijheatmasstransfer.2016.03.127.

Torabi M, Torabi M, Peterson GP. Heat transfer and entropy generation analyses of forced convection through porous media using pore scale modeling. J Heat Transfer. 2017;139:12601. https://doi.org/10.1115/1.4034181.

Nield DA, Bejan A. Convection in porous media. 4th ed. New York: Springer; 2013.

Matin MH, Pop I. Forced convection heat and mass transfer flow of a nanofluid through a porous channel with a first order chemical reaction on the wall. Int Commun Heat Mass Transf. 2013;46:134–41. https://doi.org/10.1016/j.icheatmasstransfer.2013.05.001.

Chen J, Song W, Gao X, Xu D. Hetero-/homogeneous combustion and flame stability of fuel-lean propane–air mixtures over platinum in catalytic micro-combustors. Appl Therm Eng. 2016;100:932–43. https://doi.org/10.1016/j.applthermaleng.2016.02.122.

Wang P, Vafai K, Liu DY. Analysis of radiative effect under local thermal non-equilibrium conditions in porous media-application to a solar air receiver. Numer Heat Transf Part A Appl. 2014;65:931–48. https://doi.org/10.1080/10407782.2013.850917.

Torabi M, Zhang Z, Peterson GP. Interface entropy generation in micro porous channels with velocity slip and temperature jump. Appl Therm Eng. 2017;111:684–93. https://doi.org/10.1016/j.applthermaleng.2016.09.148.

Modest MF. Radiative heat transfer. Amsterdam: Elsevier; 2013. https://doi.org/10.1016/b978-0-12-386944-9.50022-4.

Kaisare NS, Vlachos DG. A review on microcombustion: fundamentals, devices and applications. Prog Energy Combust Sci. 2012;38:321–59. https://doi.org/10.1016/j.pecs.2012.01.001.

Torabi M, Peterson GP. Effects of velocity slip and temperature jump on the heat transfer and entropy generation in micro porous channels under magnetic field. Int J Heat Mass Transf. 2016;102:585–95. https://doi.org/10.1016/j.ijheatmasstransfer.2016.06.080.

Ibáñez G, López A, Pantoja J, Moreira J. Combined effects of uniform heat flux boundary conditions and hydrodynamic slip on entropy generation in a microchannel. Int J Heat Mass Transf. 2014;73:201–6. https://doi.org/10.1016/j.ijheatmasstransfer.2014.02.007.

Ibáñez G. Entropy generation in MHD porous channel with hydrodynamic slip and convective boundary conditions. Int J Heat Mass Transf. 2015;80:274–80. https://doi.org/10.1016/j.ijheatmasstransfer.2014.09.025.

Ibáñez G, López A, Pantoja J, Moreira J. Entropy generation analysis of a nanofluid flow in MHD porous microchannel with hydrodynamic slip and thermal radiation. Int J Heat Mass Transf. 2016;100:89–97. https://doi.org/10.1016/j.ijheatmasstransfer.2016.04.089.

Karimi N, Agbo D, Talat Khan A, Younger PL. On the effects of exothermicity and endothermicity upon the temperature fields in a partially-filled porous channel. Int J Therm Sci. 2015;96:128–48. https://doi.org/10.1016/j.ijthermalsci.2015.05.002.

Yang K, Vafai K. Analysis of temperature gradient bifurcation in porous media—an exact solution. Int J Heat Mass Transf. 2010;53:4316–25. https://doi.org/10.1016/j.ijheatmasstransfer.2010.05.060.

Lu J, Das S, Peters EAJF, Kuipers JAM. Direct numerical simulation of fluid flow and mass transfer in dense fluid-particle systems with surface reactions. Chem Eng Sci. 2017;176:1–18. https://doi.org/10.1016/j.ces.2017.10.018.

Mashaei PR, Shahryari M, Madani S. Numerical hydrothermal analysis of water-Al2O3 nanofluid forced convection in a narrow annulus filled by porous medium considering variable properties: application to cylindrical heat pipes. J Therm Anal Calorim. 2016;126:891–904. https://doi.org/10.1007/s10973-016-5550-3.

Torabi M, Dickson C, Karimi N. Theoretical investigation of entropy generation and heat transfer by forced convection of copper–water nanofluid in a porous channel—local thermal non-equilibrium and partial filling effects. Powder Technol. 2016;301:234–54. https://doi.org/10.1016/j.powtec.2016.06.017.

Acknowledgements

Lilian Govone was funded through Erasmus Programme, and Linwei Wang acknowledges the financial support of Chinese Scholarship Council.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Govone, L., Torabi, M., Wang, L. et al. Effects of nanofluid and radiative heat transfer on the double-diffusive forced convection in microreactors. J Therm Anal Calorim 135, 45–59 (2019). https://doi.org/10.1007/s10973-018-7027-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7027-z