Abstract

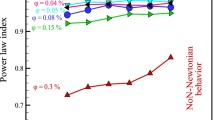

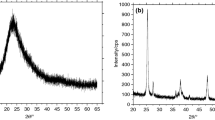

Nanofluids are prepared by suspending the nanoparticles in the base fluid and can be substantially enhanced the heat transfer rate compared to the pure fluids. In this paper, experimental investigation of the effects of volume concentration and temperature on dynamic viscosity of the hybrid nanofluid of multi-walled carbon nanotubes and aluminum oxide in a mixture of water (80%) and ethylene-glycol (20%) has been presented. The nanofluid was prepared with solid volume fractions between 0.0625 and 1%, and experiments were performed in the temperature range of 25–50 °C. The measurement results at different shear rates showed that the base fluid and nanofluid samples with solid volume fractions of less than 0.5% had Newtonian behavior, while those with higher solid volume fractions (0.75 and 1%) exhibit a pseudoplastic rheological behavior with a power law index of less than unity. The results showed that viscosity has a direct relationship with solid volume fraction of the nanofluid. The value of maximum enhancement is which occurred in 25 °C. Moreover, the consistency index and power law index have been obtained by accurate curve fitting for samples with non-Newtonian behavior of nanofluids. The results also revealed that the apparent viscosity generally increases with an increase in the solid volume fraction.

Similar content being viewed by others

Abbreviations

- d :

-

Diameter (nm)

- m :

-

Mass (kg)

- T :

-

Temperature (°C)

- \(\phi\) :

-

Solid volume fraction (%)

- \(\gamma\) :

-

Shear rate (s−1)

- \(\mu\) :

-

Dynamic viscosity (kg m−1 s−1)

- \(\rho\) :

-

Density (kg m−3)

- \(\tau\) :

-

Shear stress (mPa)

- bf:

-

Base fluid

- Exp:

-

Experimental data

- nf:

-

Nanofluid

- Pred:

-

Predicted value

- MWCNT:

-

Multi walled carbon nanotubes

- Al2O3 :

-

Alumina

- EG:

-

Ethylene glycol

References

Rezaei M, Azimian AR, Toghraie D. The surface charge density effect on the electro-osmotic flow in a nanochannel: a molecular dynamics study. Heat Mass Transf. 2015;51(5):661–70.

Dardan E, Afrand M, Isfahani AM. Effect of suspending hybrid nano-additives on rheological behavior of engine oil and pumping power. Appl Therm Eng. 2016;109:524–34.

Afrand M, Najafabadi KN, Sina N, Safaei MR, Kherbeet AS, Wongwises S, Dahari M. Prediction of dynamic viscosity of a hybrid nano-lubricant by an optimal artificial neural network. Int Commun Heat Mass Transf. 2016;76:209–14.

Vafaei M, Afrand M, Sina N, Kalbasi R, Sourani F, Teimouri H. Evaluation of thermal conductivity of MgO–MWCNTs/EG hybrid nanofluids based on experimental data by selecting optimal artificial neural networks. Physica E. 2017;85:90–6.

Afrand M. Experimental study on thermal conductivity of ethylene glycol containing hybrid nano-additives and development of a new correlation. Appl Therm Eng. 2017;110:1111–9.

Rezaei M, Azimian AR, Toghraie D. Molecular dynamics study of an electro-kinetic fluid transport in a charged nanochannel based on the role of the stern layer. Physica A: Stat Mech Appl. 2015;426:25–34.

Afrand M, Nadooshan AA, Hassani M, Yarmand H, Dahari M. Predicting the viscosity of multi-walled carbon nanotubes/water nanofluid by developing an optimal artificial neural network based on experimental data. Int Commun Heat Mass Transf. 2016;77:49–53.

Afrand M, Farahat S, Nezhad AH, Sheikhzadeh GA, Sarhaddi F. Numerical simulation of electrically conducting fluid flow and free convective heat transfer in an annulus on applying a magnetic field. Heat Transf Res. 2014;45:749–66.

Gravndyan Q, Akbari OA, Toghraie D, Marzban A, Mashayekhi R, Karimi R, Pourfattah F. The effect of aspect ratios of rib on the heat transfer and laminar water/TiO 2 nanofluid flow in a two-dimensional rectangular microchannel. J Mol Liq. 2017;236:254–265. https://doi.org/10.1007/s10973-017-6711-8

Shahsavani E, Afrand M, Kalbasi R. Using experimental data to estimate the heat transfer and pressure drop of non-Newtonian nanofluid flow through a circular tube: applicable for use in heat exchangers. Appl Therm Eng. 2018;129:1573–81.

Mahmoodi M, Esfe MH, Akbari M, Karimipour A, Afrand M. Magneto-natural convection in square cavities with a source-sink pair on different walls, nt. J Appl Electromagn Mech. 2015;47:21–32.

Afrand M, Toghraie D, Karimipour A, Wongwises S. A numerical study of natural convection in a vertical annulus filled with gallium in the presence of magnetic field. J Magn Magn Mater. 2017;430:22–8.

Tohidi M, Toghraie D. The effect of geometrical parameters, roughness and the number of nanoparticles on the self-diffusion coefficient in Couette flow in a nanochannel by using of molecular dynamics simulation. Physica B: Condensed Matt. 2017;518:20–32.

Shamsi MR, Akbari OA, Marzban A, Toghraie D, Mashayekhi R. Increasing heat transfer of non-Newtonian nanofluid in rectangular microchannel with triangular ribs. Physica E: Low-dimensional Syst Nanostruct. 2017;93:167–178.

Afrand M. Using a magnetic field to reduce natural convection in a vertical cylindrical annulus. Int J Therm Sci. 2017;118:12–23.

Afrand M, Farahat S, Nezhad AH, AliSheikhzadeh G, Sarhaddi F. 3-D numerical investigation of natural convection in a tilted cylindrical annulus containing molten potassium and controlling it using various magnetic fields. Int J Appl Electromagn Mech. 2014;46(4):809–21.

Teimouri H, Afrand M, Sina N, Karimipour A, Isfahani AHM. Natural convection of liquid metal in a horizontal cylindrical annulus under radial magnetic field. Int J Appl Electromagn Mech. 2015;49:453–61.

Namburu PK, Kulkarni DP, Misra D, Das DK. Viscosity of copper oxide nanoparticles dispersed in ethylene glycol and water mixture. Exp Therm Fluid Sci. 2007;32(2):397–402.

Chen H, Ding Y, Tan C. Rheological behaviour of nanofluids. New J Phys. 2007;9(10):367.

Chen H, Ding Y, Lapkin A. Rheological behaviour of nanofluids containing tube/rod-like nanoparticles. Powder Technol. 2009;194(1):132–41.

Masoumi N, Sohrabi N, Behzadmehr A. A new model for calculating the effective viscosity of nanofluids. J Phys D Appl Phys. 2009;42(5):1–6.

Fedele L, Colla L. Bobbo S Viscosity and thermal conductivity measurements of water-based nanofluids containing titanium oxide nanoparticles. Int J Refrig. 2012;35(5):1359–66.

Mahbubul IM, Saidur R, Amalina MA. Investigation of viscosity of R123-TiO2 nanorefrigerant. Int J Mech Mater Eng. 2012;7(2):146–51.

Mishra PC, Mukherjee S, Nayak SK, Panda A. A brief review on viscosity of nanofluids. Int Nano Lett. 2014;4(4):109–20.

Anoop K, Sadr R, Al-Jubouri M, Amani M. Rheology of mineral oil-SiO2 nanofluids at high pressure and high temperatures. Int J Therm Sci. 2014;77:108–15.

Nwosu PN, Meyer J, Sharifpur M. Review and parametric investigation into nanofluid viscosity models. J Nanotechnol Eng Med. 2007;32(2):397–402.

Li X, Zou C, Wang T, Lei X. Rheological behavior of ethylene glycol-based SiC nanofluids. Int J Heat Mass Transf. 2015;84:925–30.

Ghozatloo A, Azimi MS, Shariaty-Niassar M, Morad Rashidi A. Investigation of nanoparticles morphology on viscosity of nanofluids and new correlation for prediction. J Nanostruct. 2015;5:161–8.

Etaig S, Hasan R, Perera N. Investigation of a new effective viscosity model for nanofluids. Proc Eng. 2016;157:404–13.

Issa RJ. Effect of nanoparticles size and concentration on thermal and rheological properties of Al2O3–water nanofluids. 2016; Paper No. ENFHT 101.

Auriemma M, Iazzetta A. Viscosity of alumina water-based nanofluids modeling by artificial neural network. Indian J Sci Technol. 2017. https://doi.org/10.17485/ijst/2016/v9i48/91743.

Kavosh M. The viscosity study of CuO nanofluid based on propylene glycol. Int J Math Phys Sci Res. 2016;4(1):96–103.

Zhao N, Li Z. Viscosity prediction of different ethylene glycol/water based nanofluids using a RBF neural network. Appl Sci. 2017;7(4):409.

Esfe MH. The investigation of effects of temperature and nanoparticles volume fraction on the viscosity of copper oxide–ethylene glycol nanofluids. Period Polytech Chem Eng. 2018. https://doi.org/10.3311/PPch.9741.

Esfe MH, Saedodin S, Bahiraei M, Toghraie D, Mahian O, Wongwises S. Thermal conductivity modeling of MgO/EG nanofluids using experimental data and artificial neural network. J Therm Anal Calorim. 2014;118(1):287–94.

Zarringhalam M, Karimipour A, Toghraie D. Experimental study of the effect of solid volume fraction and Reynolds number on heat transfer coefficient and pressure drop of CuO–water nanofluid. Exp Therm Fluid Sci. 2016;76:342–51.

Esfe MH, Akbari M, Semiromi DT, Karimiopour A, Afrand M. Effect of nanofluid variable properties on mixed convection flow and heat transfer in an inclined two-sided lid-driven cavity with sinusoidal heating on sidewalls. Heat Transf Res. 2014;45(5):409–32.

Afrand M, Toghraie D, Ruhani B. Effects of temperature and nanoparticles concentration on rheological behavior of Fe3O4–Ag/EG hybrid nanofluid: an experimental study. Exp Therm Fluid Sci. 2016;77:38–44.

Esfe MH, Yan WM, Afrand M, Sarraf M, Toghraie D, Dahari M. Estimation of thermal conductivity of Al2O3/water (40%)–ethylene glycol (60%) by artificial neural network and correlation using experimental data. Int Commun Heat Mass Transf. 2016;74:125–8.

Toghraie D, Chaharsoghi VA, Afrand M. Measurement of thermal conductivity of ZnO–TiO2/EG hybrid nanofluid. J Therm Anal Calorim. 2016;125(1):527–35.

Toghraie D, Alempour SM, Afrand M. Experimental determination of viscosity of water based magnetite nanofluid for application in heating and cooling systems. J Magn Magn Mater. 2016;417:243–8.

Esfe MH, Saedodin S, Wongwises S, Toghraie D. An experimental study on the effect of diameter on thermal conductivity and dynamic viscosity of Fe/water nanofluids. J Therm Anal Calorim. 2015;119(3):1817–24.

Esfe MH, Afrand M, Gharehkhani S, Rostamian H, Toghraie D, Dahari M. An experimental study on viscosity of alumina-engine oil: effects of temperature and nanoparticles concentration. Int Commun Heat Mass Transf. 2016;76:202–8.

Esfe MH, Afrand M, Yan WM, Yarmand H, Toghraie D, Dahari M. Effects of temperature and concentration on rheological behavior of MWCNTs/SiO2 (20–80)-SAE40 hybrid nano-lubricant. Int Commun Heat Mass Transf. 2016;76:133–8.

Esfe MH, Ahangar MRH, Rejvani M, Toghraie D, Hajmohammad MH. Designing an artificial neural network to predict dynamic viscosity of aqueous nanofluid of TiO2 using experimental data. Int Commun Heat Mass Transf. 2016;75:192–6.

Afrand M, Toghraie D, Sina N. Experimental study on thermal conductivity of water-based Fe3O4 nanofluid: development of a new correlation and modeled by artificial neural network. Int Commun Heat Mass Transf. 2016;75:262–9.

Esfahani MA, Toghraie D. Experimental investigation for developing a new model for the thermal conductivity of silica/water–ethylene glycol (40%–60%) nanofluid at different temperatures and solid volume fractions. J Mol Liq. 2017;232:105–12.

Esfe MH, Afrand M, Rostamian SH, Toghraie D. Examination of rheological behavior of MWCNTs/ZnO-SAE40 hybrid nano-lubricants under various temperatures and solid volume fractions. Exp Therm Fluid Sci. 2017;80:384–90.

Esfe MH, Rostamian H, Toghraie D, Yan WM. Using artificial neural network to predict thermal conductivity of ethylene glycol with alumina nanoparticle. J Therm Anal Calorim. 2016;126(2):643–8.

Zadkhast M, Toghraie D, Karimipour A. Developing a new correlation to estimate the thermal conductivity of MWCNT-CuO/water hybrid nanofluid via an experimental investigation. J Therm Anal Calorim. 2017;129:859–67.

Esfe MH, Hajmohammad H, Toghraie D, Rostamian H, Mahian O, Wongwises S. Multi-objective optimization of nanofluid flow in double tube heat exchangers for applications in energy systems. Energy. 2017;137:160–71.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Afshari, A., Akbari, M., Toghraie, D. et al. Experimental investigation of rheological behavior of the hybrid nanofluid of MWCNT–alumina/water (80%)–ethylene-glycol (20%). J Therm Anal Calorim 132, 1001–1015 (2018). https://doi.org/10.1007/s10973-018-7009-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7009-1