Abstract

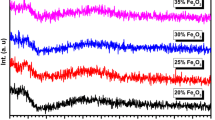

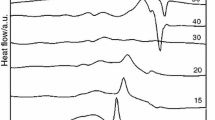

Differential scanning calorimetry (DSC), dilatometry and X-ray diffraction have been used to study thermal behavior and stability of glasses prepared simultaneously in Al2O3 or Pt crucibles in compositional series (40 − x)MgO–xFe2O3–60P2O5 within the concentration range of x = 0–40 mol% Fe2O3. Mössbauer spectra showed that all glasses with Fe2O3 contained both Fe(II) and Fe(III) ions. The contamination glasses from alumina crucibles ranged from 0.3 to 0.9 mol% Al2O3. The replacement of MgO by Fe2O3 resulted in a gradual decrease in glass transition temperature and dilatometric softening temperature, whereas thermal expansion coefficient did not change significantly. The DSC curves showed that all glasses crystallize on heating in the broad temperature range ≈ 560–900 °C. Crystallization temperature decreases with increasing Fe2O3 content. The highest tendency toward crystallization was found for the glass containing 40 mol% Fe2O3. X-ray diffraction measurements showed that the major compounds formed by glass crystallization were Mg(PO3)2, Fe(PO3)3, Fe3(P2O7)2 and FePO4. All thermoanalytical studies showed differences in thermal behavior of glasses prepared in Al2O3 or Pt crucibles.

Similar content being viewed by others

References

Peng YB, Day DE. High thermal expansion phosphate glasses. Part 1. Glass Technol. 1991;32:166–73.

Brauer DS, Rüssel C, Kraft J. Solubility of glasses in the system P2O5–CaO–MgO–Na2O–TiO2: experimental and modeling using artificial neural networks. J Non Cryst Solids. 2007;353:263–70.

Mesko MG, Day DE, Bunker BC. Science and technogy for disposal of radioactive tank wastes. New York: Plenium Press; 1997. p. 379–92.

Yu X, Day DE, Long GJ, Brow RK. Properties and structure of sodium-iron phosphate glasses. J Non Cryst Solids. 1997;215:21–31.

Day DE, Wu Z, Ray CS, Hrma P. Chemically durable iron phosphate glass wasteforms. J Non Cryst Solids. 1998;241:1–12.

Marasinghe GK, Karabulut M, Ray CS, Day DE, Shuh DK, Allen PG, Saboungi ML, Grimsditch M, Haeffner D. Properties and structure of vitrified iron phosphate nuclear wasteforms. J Non Cryst Solids. 2000;263–264:146–54.

Mesko MG, Day DE, Bunker BC. Immobilization of CsCl and SrF2 in iron phosphate glass. Waste Manag. 2000;20:271–8.

Huang W, Day DE, Ray CS, Kim CW, Mogus-Milanković A. Vitrification of high chrome oxide nuclear waste in iron phosphate glasses. J Nucl Mater. 2004;327:46–57.

Donald IW, Metcalfe BL, Fong SK, Gerrard LA. The influence of Fe2O3 and B2O3 additions on the thermal properties, crystallization kinetics and durability of a sodium aluminum phosphate glass. J Non Cryst Solids. 2006;352:2993–3001.

Marasinghe GK, Karabulut M, Ray CS, Day DE, Shumsky MG, Yelon WB, Booth CH, Allen PG, Shuh DK. Structural features of iron phosphate glasses. J Non Cryst Solids. 1997;222:144–52.

Donald IW, Metcalfe BL, Fong SK, Gerrard LA, Strachan DM, Scheele RD. A glass-encapsulated calcium phosphate wasteform for the immobilization of actinide-, fluoride-, and chloride-containing radioactive wastes from the pyrochemical reprocessing of plutonium metal. J Nucl Mater. 2007;361:78–93.

Fang X, Ray CS, Moguš-Milanković A. Iron redox equilibrium, structure and properties of iron phosphate glasses. J Non Cryst Solids. 2001;283:162–72.

Kitheri J. Non-isothermal crystallization in BaO–Fe2O3–P2O5 glasses. A comparison with iron phosphate and Cs2O–Fe2O3–P2O5 glasses. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s10973-017-6361-x.

Stoch P, Ciecinska M, Stoch A. Thermal properties of phosphate glasses for salt waste immobilization. J Therm Anal Calorim. 2014;117:197–204.

Mesko MG, Day DE. Immobilization of spent nuclear fuel in iron phosphate glass. J Nucl Mater. 1999;273:27–36.

Karabulut M, Marasinghe GK, Ray CS, Day DE, Ozturk O, Waddill GD. X-ray photoelectron and Mössbauer spectroscopic studies of iron phosphate glasses containing U Cs and Bi. J. Non Cryst Solids. 1999;249:106–16.

Reis ST, Karabulut M, Day DE. Chemical durability and structure of zinc-iron phosphate glasses. J Non Cryst Solids. 2001;292:150–7.

Donald IW, Metcalfe BL, Taylor RNJ. The immobilization of high level radioactive wastes using ceramics and glasses. J Mater Sci. 1997;32:5851–7.

Metcalfe BL, Fong SK, Donald IW. Preparation, thermal characterisation and chemical durability of calcium iron phosphate glasses. Glass Technol. 2005;46:130–4.

Bingham PA, Hand RJ, Hannant OM, Forde SD, Kilcoyne SH. Effects of modifier additions on the thermal properties, chemical durability, oxidation state and structure of iron phosphate glasses. J Non Cryst Solids. 2009;355:1526–38.

Yu X, Day DE. Effect of raw materials on the redox state of iron and properties of iron phosphate glasses. In: Proceedings of the 17th international congress on glass, Beijing 1995, vol 2, p 45–9

Zhu D, Ray CS, Zhou W, Day DE. Glass transition and fragility of Na2O-TeO2 glasses. J Non Cryst Solids. 2003;319:247–56.

Doupovec J, Sitek J, Kákoš J. Crystallization of iron phosphate glasses. J Therm Anal. 1981;22:213–9.

Ray CS, Yang Q, Huang W, Day DE. Surface and internal crystallization in glasses as determined by differential thermal analysis. J Am Ceram Soc. 1996;79:3155–60.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mošner, P., Račický, A. & Koudelka, L. Thermal properties and crystallization of MgO–FeOx–P2O5 glasses. J Therm Anal Calorim 132, 843–850 (2018). https://doi.org/10.1007/s10973-018-6981-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-6981-9