Abstract

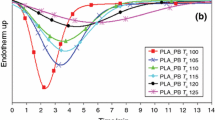

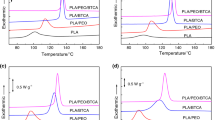

Nucleated polylactide (PLA) blend films with various types and contents of nucleating agent were prepared in a twin-screw extruder. The influences of type and level of nucleating agent on the tensile, thermal, and morphological properties of the blend films were investigated. Furthermore, effects of different cooling rates (1–10 °C min−1) on non-isothermal processes and various crystallization temperatures (T c) (100–125 °C) on isothermal conditions were used to evaluate the crystallization behaviors and kinetics of these films by differential scanning calorimeter (DSC) and polarized light microscope. Nanoprecipitated calcium carbonate (NPCC) and talc were used as a nucleating agent at different concentrations from 0 to 2 phr. The results showed that the tensile properties, thermal stability, spherulitic morphology, and crystallization behaviors of the nucleated PLA blends significantly depended upon the addition of nucleating agent. Tensile properties of the blends were improved with increasing of nucleating agent contents; in contrast, its thermal stability decreased. These behaviors were similarly observed in both nucleated PLA blends with NPCC and talc. Furthermore, DSC curves revealed that NPCC and talc could be a proficient nucleating agent for PLA, resulting in the increments of T c, crystallization rate, degree of crystallinity (χ c), and spherulitic density of nucleated PLA films.

Similar content being viewed by others

References

Xiao H, Lu W, Yeh JT. Crystallization behavior of fully biodegradable poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends. J Appl Polym Sci. 2009;112:3754–63.

Nam BU, Min KD, Son Y. Investigation of the nanostructure, thermal stability, and mechanical properties of polylactic acid/cellulose acetate butyrate/clay nanocomposites. Mater Lett. 2015;150:118–21.

Kelnar I, Kratochvil J, Kapralkova L. Crystallization and thermal properties of melt-drawn PCL/PLA microfibrillar composites. J Therm Anal Calorim. 2016;124:799–805.

Wang Y, Chiao SM, Hung TF, Yang SY. Improvement in toughness and heat resistance of poly(lactic acid)/polycarbonate blend through twin-screw blending: influence of compatibilizer type. J Appl Polym Sci. 2012;125:E402–12.

Shi X, Zhang G, Phuong TV, Lazzeri A. Synergistic effects of nucleating agents and plasticizers on the crystallization behavior of poly(lactic acid). Molecules. 2015;20(1):1579–93.

Li C, Dou Q, Bai Z, Lu Q. Non-isothermal crystallization behaviors and spherulitic morphology of poly(lactic acid) nucleated by a novel nucleating agent. J Therm Anal Calorim. 2015;122:407–17.

Akos NI, Wahit MU, Mohamed R, Yussuf AA. Preparation, characterization, and mechanical properties of poly(ε-caprolactone)/polylactic acid blend composites. Polym Compos. 2013;34:763–8.

Blanco I, Siracusa V. Kinetic study of the thermal and thermooxidative degradations of polylactide-modified films for food packaging. J Therm Anal Calorim. 2013;112:1171–7.

Arrieta MP, Lopez J, Hernandez A, Rayon E. Ternary PLA–PHB–Limonene blends intended for biodegradable food packaging applications. Eur Polym J. 2014;50:255–70.

Henricks J, Boyum M, Zheng W. Crystallization kinetics and structure evolution of a polylactic acid during melt and cold crystallization. J Therm Anal Calorim. 2015;120:1765–74.

Battegazzore D, Bocchini S, Frache A. Crystallization kinetics of poly(lactic acid)-talc composites. Express Polym Lett. 2011;5:849–58.

Wypych G. Handbook of plasticizers: chapter 7. In: Wypych G, editor. Plasticizer motion and diffusion. Toronto: ChemTec Publishing; 2004. pp. 159–160.

Ali I, Elleithy R, Al-Zahrani SM, Ali Mohsin ME. Viscoelastic, thermal, and morphological analysis of HDPE/EVA/CaCO3 ternary blends. Polym Bull. 2011;67:1961–78.

Jiang XL, Luo SJ, Sun K, Chen XD. Effect of nucleating agents on crystallization kinetics of PET. Express Polym Lett. 2007;1:245–51.

Hanim H, Ahmad Fuad MY, Zarina R, Mohd Ishak ZA, Hassan A. Properties and structure of polypropylene/polyethylene-octene elastomer/nano CaCO3 composites. J Thermoplast Compos. 2008;21:123–40.

Zhang YF. Comparison of nucleation effects of organic phosphorous and sorbital derivative nucleating agents in isotactic polypropylene. J Macromol Sci, Phys. 2008;47:1188–96.

Huang JW, Hung YC, Wen YL, Kang CC, Yeh MY. Polylactide/nano- and micro-scale silica composite films. II. Melting behavior and cold crystallization. J Appl Polym Sci. 2009;112:3149–56.

Fowlks AC, Narayan R. The effect of maleated polylactic acid (PLA) as an interfacial modifier in PLA-talc composites. J Appl Polym Sci. 2010;118:2810–20.

Xiao H, Yang L, Ren X, Jiang T, Yeh JT. Kinetics and crystal structure of poly(lactic acid) crystallized nonisothermally: effect of plasticizer and nucleating agent. Polym Compos. 2010;31:2057–68.

Cai Y, Yan S, Yin J, Fan Y, Chen X. Crystallization behavior of biodegradable poly(L-lactic acid) filled with a powerful nucleating agent: N, N′-Bis (benzoyl) suberic acid dihydrazide. J Appl Polym Sci. 2011;121:1408–16.

Wilbrink MWJ, Argon AS, Cohen RE, Weinberg M. Toughen-ability of Nylon 6 with CaCO3 filler particles: new findings and general principles. Polymer. 2001;42:10155–80.

Bartczak Z, Argon AS, Cohen RE, Weinberg M. The morphology and orientation of polyethylene in films of sub-micron thickness crystallized in contact with calcite and rubber substrates. Polymer. 1999;40:2367–80.

Huda M, Drzal L, Misra M. A study on green composites from recycled newspaper fiber reinforced poly(lactic acid). Ind Eng Chem Res. 2005;44:5593–601.

Wang H, Sun XZ, Seib PJ. Strengthening blends of poly(lactic acid) and starch with methylenediphenyl diisocyanate. Appl Polym Sci. 2001;82:1761–7.

Phetwarotai W, Aht-Ong D. Properties and nonisothermal crystallization behavior of nucleated polylactide biodegradable composite films. Adv Mater Res. 2012;488–489:671–5.

Tabi T, Sajo IE, Szabo F, Luyt AS, Kovacs JG. Crystalline structure of annealed polylactic acid and its relation to processing. Express Polym Lett. 2010;4:659–68.

Lee JH, Jeong YG. Preparation and crystallization behavior of polylactide nanocomposites reinforced with poss-modified montmorillonite. Fiber Polym. 2011;12:180–9.

Gedde UFLW. Polymer physics. 1st ed. London: Chapman & Hall; 1995.

Hwang JJ, Huang SM, Liu HJ, Chu HC, Lin LH, Chung CS. Crystallization kinetics of poly(L-lactic acid)/montmorillonite nanocomposites under isothermal crystallization condition. J Appl Polym Sci. 2012;124:2216–26.

Xiao HW, Li P, Ren X, Jiang T, Yeh JT. Isothermal crystallization kinetics and crystal structure of poly(lactic acid): effect of triphenyl phosphate and talc. J Appl Polym Sci. 2010;118:3558–69.

Acknowledgements

The authors acknowledged the financial support from Ratchadapiseksomphot Endowment Fund, Chulalongkorn University (cu-58-034-AM) and The 90th Anniversary of Chulalongkorn University Fund. Additionally, this research was partially supported by Ratchadapiseksomphot Endowment under Outstanding Research Performance Program (GF_58_08_23_01). W. Phetwarotai gratefully thanks the Development and Promotion of Science and technology Talents project (DPST).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Phetwarotai, W., Aht-Ong, D. Nucleated polylactide blend films with nanoprecipitated calcium carbonate and talc. J Therm Anal Calorim 127, 2367–2381 (2017). https://doi.org/10.1007/s10973-016-5802-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5802-2