Abstract

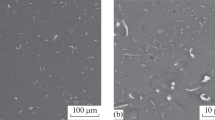

Differential barothermal analysis (DBA or HP-DTA) of the phase transformations in hypoeutectic Al-10 at.% Si and eutectic Al-12 at.% Si alloys was carried out at 100 MPa of argon pressure and at temperatures up to 700 °C. Liquidus temperature of Al-10 at.% Si is reduced during melting and crystallization by 3–4 °C as compared with the atmospheric pressure data. Increase in the eutectic transformation L → (Al) + Si temperature up to 580–581 °C during heating was found for the Al-10 at.% Si and Al-12 at.% Si alloys. According to the barothermography data, a slight thermal effect at 553 °C is detected for both alloys, which was identified as the decomposition of aluminum-based solid solution and precipitation of silicon particles. The improvement of silicon phase morphology for Al-10 at.% Si and Al-12 at.% Si alloys after hot isostatic pressing (HIP) at the pressure of 100 MPa and temperature of 550 °C was found. No porosity in the alloy has been established after HIP treatment. After HIP thermal expansion, coefficients of the alloy are noticeably decreased by 25 (Al-10 at.% Si) and 50 % (Al-12 at.% Si).

Similar content being viewed by others

References

Prigunova AG, Belov NA, Taran Yu N, et al. Siluminy. Atlas mikrostruktur i fraktogramm (Silumins: atlas of microstructures and fracture surface maps), Moscow: Mosk. Inst. Stali i Splavov; 1996.

Westerlund J, Vimercati A. Four decades of HIP progress. Met Powder Rep. 2000;55(2):14–21.

Padalko AG. Praktika goryachego izostaticheskogo pressovaniya neorganicheskikh materialov (Practical issues in hot isostatic pressing of inorganic materials). Moscow: Akademkniga; 2007. p. 267.

Murray JL, McAlister AJ. The Al–Si (aluminum–silicon) system. Bull. Alloy Phase Diagr. 1984;5(1):74–84.

Diagrammy sostoyaniya dvoinykh metallicheskikh system (phase diagrams of binary metallic systems). In: Lyakishev NP, editor. Moscow: Mashinostroenie; 1996, vol. 1, p. 991; 1997, vol. 2, p. 1024; 2001, vol. 3, part 1, p. 872; 2001, vol. 3, part 2, p. 448.

Kablov EN, Golubovskii ER. Zharoprochnost’ nikelevykh splavov (High-Temperature Strength of Nickel Alloys). Moscow: Mashinostroenie; 2005.

Fujishiro I, Mii H, Senoo M, Akao M. High pressure phase diagram of Al–Si system. J Soc Mater Sci Jpn. 1971;20(215):952–5.

Mii H, Senoo M, Fujishiro I. Solid solubility of Si in Al under high pressure. Jpn J Appl Phys. 1976;15(5):777–83.

Padalko AG, Veselov AN, Avduhin SP. Differential barothermal analysis (DBA) of Ni-base alloys. J Therm Anal Calorim. 2003;72(3):791–7.

Padalko AG, Belov NA, Veselov AN, Talanova GV. Thermography of the phase transformations in a hypoeutectic Al–7% Si–0.5% Mg silumin at high pressures and temperatures. Russ Metall. 2009;1:60–9.

Padalko AG, Talanova GV, Zubarev GI, et al. Thermography of the phase transformations in nickel-based eutectic alloys at high pressures and temperatures. Russ Metall. 2011;3:169–74.

Padalko AG, Talanova GV, Ponomareva EY, et al. Phase transformations at high pressures and temperatures and the structure of a hypoeutectic 1Ni–99Al alloy. Russ Metall. 2012;9:779–85.

Padalko AG, Talanova GV, Ponomareva EY, et al. Barothermal analysis and structure of the eutectic Al–Ni (2.7 at% Ni) alloy. Inorg Mater. 2012;48(6):582–7.

Tonkov EY. Fazovye prevrashcheniya soedinenii pri vysokom davlenii (High-Pressure Phase Transformations of Compounds), vol. 1–2. Moscow: Metallurgiya; 1988. p. 791.

Dobatkin VI, Elagin VI. Granuliruemye alyuminievye splavy (Granulable aluminum alloys). Moscow: Metallurgiya; 1981.

Ceschini L, Morri A, Sambogna G. The effect of hot isostatic pressing on the fatigue behavior of sand-cast A356-T6 and A204-T6 aluminum alloys. J Mater Process Technol. 2008;204:231–8.

Chama CC. Distribution of Al12Fe3Si and (FeAl6)Si in a hiped Al-10.71 wt% Si casting. Mater Charact. 1996;37(4):177–81.

Acknowledgements

The research was supported by Russian Foundation for Basic Research, Grant No. 11-03-00689-a, and by the Program for Basic Research of Russian Academy of Sciences Department of Chemistry and Materials Science.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dediaeva, E., Padalko, A., Akopyan, T. et al. Barothermography and microstructure of the hypoeutectic and eutectic alloys in Al–Si system. J Therm Anal Calorim 121, 485–490 (2015). https://doi.org/10.1007/s10973-015-4731-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4731-9