Abstract

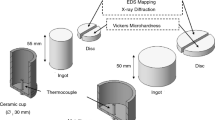

Phase transition temperatures of selected as-cast alloys from ternary Cu–Al–Ag system with overall compositions situated alongside vertical section with equal molar ratios of Ag and Cu were experimentally investigated using differential thermal analysis. Microstructures of the as-cast samples were analyzed using scanning electron microscopy with energy-dispersive spectrometry. Experimentally obtained results were compared with the results obtained by thermodynamic calculation of phase equilibria according to CALPHAD approach.

Similar content being viewed by others

References

Ma Y, Jiang C, Deng L, Xu H. Effects of composition and thermal cycle on transformation behaviors, thermal stability and mechanical properties of Cu–Al–Ag alloy. J Mater Sci Technol. 2003;19:431–4.

Gomidželović L, Pouraliakbar H, Khalaj G, Kostov A. Thermodynamic analysis of ternary Cu–Al–Ni system. J Chem Technol Metall. 2014;49:402–8.

Romčević N, Gilić M, Anžel I, Rudolf R, Mitrić M, Romčević M, Hadžić B, Joksimović D, Petrović Damjanović M, Kos M. Determination of microstructural changes by severely plastically deformed copper–aluminum alloy: optical study. J Min Metall Sect B Metall. 2014;50:61–8.

Zovko Brodarac Z, Dolić N, Unkić F. Influence of copper content on microstructure developmentof AlSi9Cu3 alloy. J Min Metall Sect B Metall. 2014;50:53–60.

Benke M, Mertinger V, Pekker P. Investigation of the beinitic reaction in a CuAlNiMnFe alloy. J Min Metall Sect B Metall. 2013;49:43–7.

Achiţei DC, Sandu AV, Abdullah MMAB, Vizureanu P, Abdullah A. On the structure of shape memory alloys. Key Eng Mater. 2014;594–595:140–5.

Stanojevic Šimšić Z, Živković D, Manasijević D, Holjevac Grgurić T, Du Y, Gojić M, Kožuh S, Kostov A, Todorović R. Thermal analysis and microstructural investigation of Cu-rich alloys in the Cu–Al–Ag system. J Alloys Compd. 2014;612:486–92.

Cimpoeşu N, Stanciu S, Vizureanu P, Cimpoeşu R, Achiţei CD, Ioniţă I. Preliminary tests of obtaining shape memory alloy thin layer through PLD technique. J Min Metall Sect B Metall. 2014;50:69–76.

Campbell W, Mathews JA. The alloys of aluminum. J Am Chem Soc. 1902;24:253–66.

Hultgren R, Desai PD, Hawkins DT, Gleiser M, Kelley KK. Selected values of thermodynamic properties of binary alloys. Metals Park, OH: American Society for Metals / ASM; 1973.

Landolt-Börnstein. Numerical data and functional relationships in science and technology (new series). Group 4: macroscopic and technical properties of matter, vol. 5, Predel B. Phase equilibria, crystallographic and thermodynamic data of binary alloys, subvol. A: Ac-Au, Au-Zr. Berlin: Springer; 1991.

Flandorfer H, Luef C, Saeed U. On the temperature dependence of the enthalpies of mixing in liquid binary (Ag, Cu, Ni) alloys. J Non Cryst Solids. 2008;354:2953–72.

Flandorfer H, Rechchach M, Elmahfoudi A, Bencze L, Popovic A, Ipser H. Enthalpies of mixing of liquid systems for lead free soldering: Al–Cu–Sn system. J Chem Thermodyn. 2011;43:1612–22.

Dowson AG. A new intermediate phase in the aluminum–copper system. J Inst Met. 1937;61:197–204.

Hume-Rothery W, Raynor GV, Reynolds PW, Packer HK. The constitution and structure of alloys of intermediate composition in the systems copper–indium, copper–aluminum, copper–germanium, silver–aluminum, and silver–germanium. J Inst Met. 1940;66:209–39.

Vigdorovich VN, Krestovnikov AN, Maltson MV. Microhardness investigation of sold solutions of ternary systems. Izv Akad Nauk SSSR Otd Tekh Nauk. 1958;3:110–3.

Linden G. Erneute Bestimmung des (α + β)-Zweiphasengebietes im system Cu–Al. Prakt Metall. 1972;9:3–14.

Liu XJ, Ohnuma I, Kainuma R, Ishida K. Phase equilibria in the Cu-rich portion of Cu–Al binary system. J Alloys Compd. 1998;264:201–8.

Labisz K, Rdzawski Z, Pawlyta M. Microstructure evaluation of long-term aged binary Cu–Ag–Cu alloy. Arch Mater Sci Eng AMSE. 2011;49:15–24.

Liu JB, Meng L. The characteristics of Cu-12wt.%Ag filamentary microcomposite in different isothermal process. Mat Sci Eng A. 2006;418:320–5.

Liu JB, Meng L, Zeng YW. Microstructure evolution and properties of Cu–Ag microcomposites with different Ag content. Mat Sci Eng A. 2006;435–436:237–44.

Fitzner K, Guo Q, Wang J, Kleppa OJ. Enthalpies of liquid–liquid mixing in the systems Cu–Ag, Cu–Au and Ag–Au by using an in situ mixing device in a high temperature single-unit differential calorimeter. J Alloys Compd. 1999;291:190–200.

Baier M, Chatillon-Colinet C, Mathieu JC. Détermination de l`enthalpie de formation de la phase β du système Ag-Al pur calorimétrie de dissolution dans l`aluminium liquid. Ann Chim Fr. 1981;6:291–6.

Spencer PJ, Kubasschewski O. A thermodynamic evaluation of the Ag–Al system. Mon Chem. 1987;118:155–67.

Lim SS, Rossiter PL, Tibballs JE. Assessment of the Al–Ag binary phase diagram. Calphad. 1995;19:131–41.

Dinsdale AT. SGTE Data for Pure Elements. Calphad. 1991;15:317–425.

Hillert M, Averbach BL, Cohen M. Thermodynamic properties of solid aluminum–silver alloys. Acta Met. 1956;4:31–6.

Witusiewicz VT, Hecht U, Fries SG, Rex S. The Ag–Al–Cu system Part I: reassessment of the constituent binaries on the basis of new experimental data. J Alloys Compd. 2004;385:133–43.

Adorno AT, Silva RAG. Effect of Ag additions on the reverse martensitic transformation in the Cu-10 mass% Al alloy. J Therm Anal Calorim. 2006;83:241–6.

Silva RAG, Adorno AT, Magdalena AG, Carvalho TM, Stipcich M, Cuniberti A, Castro ML. Thermal behavior of the Cu-22.55 at.% Al with small Ag additions. J Therm Anal Calorim. 2011;103:459–63.

Adorno AT, Silva RAG. Aging behavior in the Cu-10wt.% Al and Cu-10wt.% Al-4wt.% Ag alloys. J Alloys Compd. 2009;473:139–44.

Silva RAG, Paganottia A, Gama S, Adorno AT, Carvalho TM, Santos CMA. Investigation of thermal, mechanical and magnetic behaviors in the Cu-11wt.%Al alloy with Ag and Mn additions. Mater Charact. 2013;75:194–9.

Silva AG, Adorno AT, Carvalho TM, Magdalena AG, Santos CMA. Precipitation reaction in alpha-Cu–Al–Ag alloys. Matéria (Rio J.). 2011;16:747–53.

Adorno AT, Benedetti AV, Silva RAG, Blanco M. Influence of the Al content on the phase transformations in Cu–Al–Ag alloys. Eclet Quim. 2003;28:33–8.

Adorno AT, Guerreiro MR, Benedetti AV. Influence of silver additions on the aging characteristics of the Cu-10.4at.percent-Al alloy. J Alloys Compd. 1998;268:122–9.

Flandorfer H, Hayer E. Partial and integral enthalpy of molten Ag–Al–Cu alloys. J Alloys Compd. 2000;296:112–8.

Witusiewicz WT, Hecht U, Rex S, Sommer F. Partial and integral enthalpies of mixing of liquid Ag–Al–Cu and Ag–Cu–Zn. J Alloys Compd. 2002;337:189–201.

Hecht U, Witusiewicz VT, Drevermann A, Rex S. Orientation relationship in univariant in Al–Cu–Ag eutectic. Trans Indian Inst Met. 2005;58:545–51.

Živković D, Holjevac Grgurić T, Gojić M, Ćubela D, Stanojević Šimšić Z, Kostov A, Kožuh S. Calculation of thermodynamic properties of Cu–Al–(Ag, Au) shape memory alloy systems. Trans Indian Inst Met. 2014;67(2):285–9.

Chang YA, Goldberg D, Neumann JP. Phase diagrams and thermodynamic properties of ternary copper–silver systems. J Phys Chem Ref Data. 1977;6:621–73.

Witusiewicz VT, Hecht U, Fries SG, Rex S. The Ag–Al–Cu system II. A thermodynamic evaluation of the ternary system. J Alloys Compd. 2005;387:217–27.

Raghavan V. Ag–Al–Cu (Silver–Aluminum–Copper). JPEDAV. 2008;29:256–8.

Böyük U, Maraslı N, Çadırlı E, Kaya H, Keslioglu K. Variations of microhardness with solidification parameters and electrical resistivity with temperature for Al–Cu–Ag eutectic alloy. Curr Appl Phys. 2012;12:7–10.

Guilemany JM, Fernandez J, Zhang XM. TEM study on the microstructure of Cu–Al–Ag shape memory alloys. Mater Sci Eng A. 2006;438–440:726–9.

Böyük U, Marash N, Kaya H, Çadırlı E, Keslioglu K. Directional solidification of Al–Cu–Ag alloy. Appl Phys A. 2009;95:923–32.

Genau L, Ratke L. Crystal orientation and morphology in Al–Ag–Cu ternary eutectic. The 3rd International Conference on Advances in Solidification Processes. IOP Conference series: Mat Sci Eng A 2011;012032 doi:10.1088/1757-899X/27/1/012032.

De Wilde J, Nagels E, Lemoisson F, Froyen L. Unconstrained growth along a ternary eutectic solidification path in Al–Cu–Ag: preparation of a MAXUS sounding rocket experiment. Mater Sci Eng A. 2005;413–414:514–20.

De Wilde J, Froyen L, Witusiewicz VT, Hecht U. Two-phase planar and lamellar coupled growth along the univariant eutectic reaction in ternary alloys: an analytical approach and application to the Al–Cu–Ag system. J Appl Phys. 2005;97:1–9.

Saunders N, Miodownik AP. CALPHAD (a comprehensive guide). Oxford: Elsevier Science; 1998.

Lukas HL, Fries SG, Sundman B. Computational thermodynamics: the calphad method. Cambridge: Cambridge University Press; 2007.

Cao W, Chen SL, Zhang F, Wu K, Yang Y, Chang YA, Schmid-Fetzer R, Oates WA. PANDAT software with PanEngine, PanOptimizer and PanPrecipitation for multi-component phase diagram calculation and materials property simulation. Calphad. 2009;33:328–42.

Dinsdale AT. SGTE Unary Database, Version 4.4. 2002 (www.sgte.org).

Balanović L, Živković D, Manasijević D, Minić D, Ćosović V, Talijan N. Calorimetric investigation of Al–Zn alloys using Oelsen method. J Therm Anal Calorim. 2014;118:1287–92.

Balanović L, Živković D, Manasijević D, Minić D, Marjanović B. Calorimetric study and thermal analysis of Al–Sn system. J Therm Anal Calorim. 2013;111:1431–5.

Boettinger WJ, Kattner UR, Moon KW, Perepezko JH. DTA and heat flux DSC measurements of alloys melting and freezing. In: Zhao JC, editor. Methods for phase diagram determination. Oxford: Elsevier; 2007. p. 152–222.

Acknowledgements

This study was financially supported by the Ministry of Education, Science and Technological Development, Republic of Serbia, under the Projects OI172037, TR34005 and TR34004, which is highly acknowledged. Also, the study was conducted in the frame of ‘‘Development of new shape memory alloys” Project SVIJET—Development Program by University of Zagreb (Croatia).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Šimšić, Z.S., Manasijević, D., Živković, D. et al. Experimental investigation and characterization of selected as-cast alloys in vertical Cu0.5Ag0.5–Al section in ternary Cu–Al–Ag system. J Therm Anal Calorim 120, 149–155 (2015). https://doi.org/10.1007/s10973-015-4576-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4576-2