Abstract

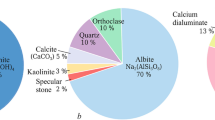

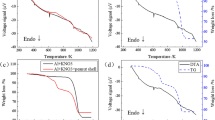

Phosphogypsum is a type of solid waste that causes severe environmental damage. To utilize phosphogypsum more effectively, the present study investigated the melting characteristics of the reaction between phosphogypsum and CaS. FactSage was used to calculate the phase equilibrium and to predict the melting behavior at high temperatures. The analysis comprised an ash-melting temperature test, thermogravimetric analysis, differential thermal analysis, and scanning electron microscopy. The results showed that kaolinite had major effects on the ash-melting temperature and the ash-melting behavior, where the effects depended on the kaolinite content. The ash-melting temperature increased with the addition of kaolinite. With a kaolinite content of 10 %, the increases in the deforming temperature, softening temperature, hemispheric temperature, and flowing temperature were 50, 42, 49, and 65 °C, respectively. The results of the simulation and experimental analyses were in good agreement.

Similar content being viewed by others

References

Parreira A, Kobayashi A, Silvestre O Jr. Influence of Portland cement type on unconfined compressive strength and linear expansion of cement-stabilized phosphogypsum. J Environ Eng. 2003;129(10):956–60.

Yang X, Zhang Z, Wang X, Yang L, Zhong B, Liu J. Thermodynamic study of phosphogypsum decomposition by sulfur. J Chem Thermodyn. 2013;57:39–45.

Rutherford P, Dudas M, Samek R. Environmental impacts of phosphogypsum. Sci Total Environ. 1994;149(1):1–38.

Tayibi H, Choura M, López FA, Alguacil FJ, López-Delgado A. Environmental impact and management of phosphogypsum. J Environ Manag. 2009;90(8):2377–86.

Alva A, Sumner M. Amelioration of acid soil infertility by phosphogypsum. Plant Soil. 1990;128(2):127–34.

Carvalho M, Van Raij B. Calcium sulphate, phosphogypsum and calcium carbonate in the amelioration of acid subsoils for root growth. Plant Soil. 1997;192(1):37–48.

El Didamony H, Abd S, Aleem E, Aziz M. Untreated phosphogypsum as a set retarder for slag cement production. Ind Ceram. 2003;23(1):19–24.

Ilić M, Miletić S, Munitlak R. Utilization of the waste phosphogypsum for the Portland cement clinker production. Toxicol Environ Chem. 1999;69(1–2):201–7.

Lutz R. Preparation of phosphoric-acid waste gypsum for further processing to make building-materials. Zement-Kalk-Gips. 1994;47(12):690.

Ma L, Ning P, Zheng S, Niu X, Zhang W, Du Y. Reaction mechanism and kinetic analysis of the decomposition of phosphogypsum via a solid-state reaction. Ind Eng Chem Res. 2010;49(8):3597–602.

Oh JS, Wheelock T. Reductive decomposition of calcium sulfate with carbon monoxide: reaction mechanism. Ind Eng Chem Res. 1990;29(4):544–50.

Ölmez H, Yilmaz V. Infrared study on the refinement of phosphogypsum for cements. Cem Concr Res. 1988;18(3):449–54.

Reijnders L. Cleaner phosphogypsum, coal combustion ashes and waste incineration ashes for application in building materials: a review. Build Environ. 2007;42(2):1036–42.

Singh M. Treating waste phosphogypsum for cement and plaster manufacture. Cem Concr Res. 2002;32(7):1033–8.

X-l Z, L-h H. Studies on technology of cement integrated with sulfuric acid produced from phosphogypsum. Shandong Chem Ind. 2007;1:008.

Aagli A, Tamer N, Atbir A, Boukbir L, El Hadek M. Conversion of phosphogypsum to potassium sulfate. J Therm Anal Calorim. 2005;82(2):395–9.

Jianxi L, Su Y, Liping M. Feasibility analysis for decomposition of phosphogypsum in cement precalciner. Environ Prog Sustain Energy. 2011;30(1):44–9.

Van der Merwe E, Strydom C, Potgieter J. Thermogravimetric analysis of the reaction between carbon and CaSO4 2H2 O, gypsum and phosphogypsum in an inert atmosphere. Thermochim Acta. 1999;340:431–7.

Strydom C, Groenewald E, Potgieter J. Thermogravimetric studies of the synthesis of cas from gypsum, CaSO4 2H2O and phosphogypsum. J Therm Anal Calorim. 1997;49(3):1501–7.

Chen JM, Yang RT. Fluidized-bed combustion of coal with lime additives. Kinetics and mechanism of regeneration of the lime sorbent. Ind Eng Chem Fundam. 1979;18(2):134–8.

Davies N, Hayhurst A. On the formation of liquid melts of CaS and CaSO4 and their importance in the absorption of SO2 by CaO. Combust Flame. 1996;106(3):359–62.

Gruncharov I, Pelovski Y, Bechev G, Dombalov I, Kirilov P. Effects of some admixtures on the decomposition of calcium sulphate. J Therm Anal. 1988;33(3):597–602.

Vorres KS. Effect of composition on melting behavior of coal ash. J Eng Gas Turbines Power. 1979;101(4):497–9.

Acknowledgements

This research was supported by the National High Technology Research and Development Program of China (Grant No. 2011AA06A106), which is gratefully acknowledged. FactSage 6.1 was provided by Kunming University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, L., Wan, T., Yang, X. et al. Effects of kaolinite addition on the melting characteristics of the reaction between phosphogypsum and CaS. J Therm Anal Calorim 119, 2119–2126 (2015). https://doi.org/10.1007/s10973-015-4400-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4400-z