Abstract

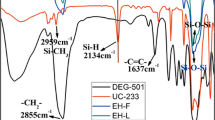

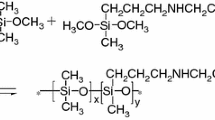

A novel polysiloxane (HPS) with epoxy and phenyl groups was synthesized by controlled hydrolysis and condensation of γ-(2,3-epoxypropoxy)propytrimethoxysilane (KH560) and diphenyl silanediol. Besides, HPS was used as the compatibilizer of the miscible diglycidyl ether of bisphenol A (DGEBA)/methyl phenyl silicone resin (Si603) blend. The structure and effect of HPS were characterized by Fourier transform infrared spectra, nuclear magnetic resonance (1H-NMR), differential scanning calorimetry, and scanning electron microscopy (SEM). The results showed that HPS could significantly improve the compatibility between epoxy resin (EP) and Si603 resin. In addition, the glass transition temperature (T g) of the blend increases with increasing amount of Si603 from 129 to 151 °C. The thermal stability of blending system was studied by thermogravimetric analysis, derivative thermogravimetric analysis and SEM. The results showed that the incorporation of Si603 into DGEBA resin not only obviously increased the thermal resistance, but also remarkably improved the flame retardancy. The high limiting oxygen index of the HPS/EP/Si603/DDM system at 31 is considered as excellent flame retardancy in the epoxy system.

Similar content being viewed by others

References

Fu SY, Zheng B. Templated silica tubes with high aspect ratios as effective fillers for enhancing the overall performance of polyimide films. Chem Mater. 2008;20:1090–8.

Wang DM, Zhang JH, Lin Q, Fu LS, Zhang HJ, Yang B. Lanthanide complex/polymer composite optical resin with intense narrow band emission, high transparency and good mechanical performance. J Mater Chem. 2003;13:2279.

Tang HY, Li WW, Fan XH, Chen XF, Shen ZH, Zhou QF. Synthesis, preparation and properties of novel high-performance allyl–maleimide resins. Polymer. 2009;50:1414.

Gojny FH, Wichmann MHG, Fiedler B, Kinloch IA, Bauhofer W, Windle AH, Schulte K. Evaluation and identification of electrical and thermal conduction mechanisms in carbon nanotube/epoxy composites. Polymer. 2006;47:2036–45.

Wetzel B, Haupert F, Qiu Zhang M. Epoxy nanocomposites with high mechanical and tribological performance. Compos Sci Technol. 2003;63:2055–67.

Rosu D, Cascaval CN, Mustata F, Ciobanu C. Cure kinetics of epoxy resins studied by non-isothermal DSC data. Thermochim Acta. 2002;383:119–27.

Smith SD, Long TE, McGrath JE. Thermogravimetric analysis of poly(alkyl methacrylates) and poly(methylmethacrylate-g-dimethyl siloxane) graft copolymers. J Polym Sci Part A. 1994;32:1747–53.

Kambour RP, Klipfer HJ, Smith SA. Limiting oxygen indices of silicone block polymers. J Appl Polym Sci. 1981;26:847.

Lin ST, Huang SK. Synthesis and characterization of siloxane-modified epoxy resin. J Polym Res. 1994;1:151.

Amerio E, Sangermano M, Malucelli G, Priola A, Rizza G. Preparation and characterization of hyperbranched polymer/silica hybrid nanocoatings by dual-curing process. Macromol Mater Eng. 2006;91:1287–92.

Mahapatra S, Singha KN. Hyperbranched polyamine/cu nanoparticles for epoxy thermoset. J Mater Sci Part A. 2009;46:296–303.

Jin FL, Park SJ. Thermal properties and toughness performance of hyperbranched-polyimide-Modified epoxy resins. J Polym Sci, Part B. 2006;44:3348–56.

Xu J, Wu H, Mills OP, Heiden PA. A morphological investigation of thermosets toughened with novel thermoplastics. I. Bismaleimide modified with hyperbranched polyester. J Appl Polym Sci. 1999;72:1065–76.

Zhang GB, Fan XD, Liu YY, Kong J, Wang SJ. Structure design of novel hyperbranched polycarbosilazanes: synthesis and characterization. J Polym. 2007;7:644–6.

Torry SA, Campbell A, Cunliffe AV, Tod DA. Kinetic analysis of organosilane hydrolysis and condensation. Int J Adhes Adhes. 2006;26:40–9.

Couchman P. Compositional variation of glass-transition temperatures. 2. Application of the thermodynamic theory to compatible polymer blends. Macromolecules. 1978;11:1156–61.

Wang WJ, Perng LH, Hsiue GH, Chang FC. Characterization and properties of new silicone-containing epoxy resin. Polymer. 2000;41:6113–22.

Sun Bin, Liang Guozheng, Aijuan Gu, Yuan Li. High performance miscible polyetherimide/bismaleimide resins with simultaneously improved integrated properties based on a novel hyperbranched polysiloxane having a high degree of branching. Ind Eng Chem Res. 2013;52:5054–65.

Gu AJ. Thermal degradation behaviour and kinetic analysis of Epoxy/montmorillonite nanocomposites. Polym Degrad Stab. 2003;80:383–91.

Kanai H, Sullivan V, Auerback A. Impact modification of engineering thermoplastics. J Appl Polym Sci. 1994;53:527.

Kambour RP. Flammability resistance synergism in BPA polycarbonate–silicone block polymers. J Appl Polym Sci. 1981;26:861.

Kambour RP, Ligon WV, Russell RP. Enhancement of the limiting oxygen index of an aromatic polycarbonate by the incorporation of silicone blocks. J Polym Sci, Part C. 1978;16:327.

Curry JE, Byrd JD. Silane polymers of diols. J Appl Polym Sci. 1965;9:295.

Wang X, Hu Y, Song L, Xing W, Lu H, Lv P, Jie G. Flame retardancy and thermal degradation mechanism of epoxy resin composites based on a DOPO substituted organophosphorus oligomer. Polymer. 2010;51:2435–45.

Dunnavant WR, Markle RA, Curry JE, Byrd JD. Synthesis of polyaryloxysilanes by melt-polymerizing dianilino-and diphenoxysilanes with aromatic diols. J Polym Sci Polym Chem Ed. 1967;5:707.

Liaw DJ, Liaw BY. Synthesis and characterization of novel polyaryloxydiphenylsilane derived from 2, 2-dimethyl-biphenyl-4,4-diol. J Polym Sci Part A. 1999;37:4591.

Wu CS, Liu YL, Chiu YS. Epoxy resins possessing flame retardant elements from silicon incorporated epoxy compounds curing with phosphorus or nitrogen containing curing agents. Polymer. 2002;43:4277–84.

Acknowledgements

We would like to thank the generous financial support by the following grant: National Natural Sciences Foundation of China, Grant no. 50973066.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Q., Bao, X., Deng, S. et al. The investigation of methyl phenyl silicone resin/epoxy resin using epoxy-polysiloxane as compatibilizer. J Therm Anal Calorim 118, 247–254 (2014). https://doi.org/10.1007/s10973-014-4017-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-4017-7