Abstract

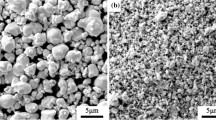

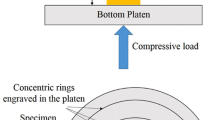

From the perspective of practical application, the development of desirable thermal and mechanical performance of solid sensible materials for thermal energy storage (TES) is highly needed. Here, we report the improved properties of nano-MgO optimized aluminate cementitious materials incorporated with Cu powders for TES. The composite TES materials were heated at 105, 350, and 900 °C, respectively. The results show that as the Cu powders content increases the thermal conductivity and volume heat capacity significantly increase, but there is a gradual decrease in compressive strength. Through the characterizations such as calorimetric test, XRD, FESEM, TG-DSC, and MIP, a significant feature of mass compensation also has been obtained, which might result from the oxidation reaction of the Cu powder at elevated temperatures.

Similar content being viewed by others

References

Jamel MS, Abdrahman A, Shamsuddin AH. Advances in the integration of solar thermal energy with conventional and non-conventional power plants. Renew Sustain Energy Rev. 2013;20:71–81.

Siegel NP. Thermal energy storage for solar power production. Wiley Interdiscip Rev Energy Environ. 2012;1(2):119–31.

Oró E, Gil A, de Gracia A, Boer D, Cabeza LF. Comparative life cycle assessment of thermal energy storage systems for solar power plants. Renew Energy. 2012;44:166–73.

Cabeza LF, Solé C, Castell A, Oro E, Gil A. Review of solar thermal storage techniques and associated heat transfer technologies. Proc IEEE. 2012;100(2):525–38.

Roman A. Simulation analysis of thermal storage for concentrating solar power. Appl Therm Eng. 2011;31(16):3588–94.

Laing D, Bahl C, Bauer T, Fiss M, Breidenbach N, Hempel M. High-temperature solid-media thermal energy storage for solar thermal power plants. Proc IEEE. 2012;100(2):516–24.

Navarro ME, Martinez M, Gil A, Fernandez AI, Cabeza LF, Olives R, Py X. Selection and characterization of recycled materials for sensible thermal energy storage. Sol Energy Mater Sol Cells. 2012;107:131–5.

Wu Z-G, Zhao C-Y. Experimental investigations of porous materials in high temperature thermal energy storage systems. Sol Energy. 2011;85(7):1371–80.

Khare S, Dell’Amico M, Mcgarry S, Knight C. Selection of materials for high temperature sensible energy storage. Sol Energy Mater Sol Cells. 2013;115:114–22.

John EE, Hale WM, Selvam RP. Development of a high-performance concrete to store thermal energy for concentrating solar power plants. In: Proceedings of ASME 2011 5th international conference on energy sustainability, ESFuelCell 2011-54177, 7–10 Aug 2011, Washington DC.

John EE, Hale WM, Selvam RP. Effects of high temperatures and heating rate on high strength concrete for use as thermal energy storage. Paper No. ES2010-90096. In: Proceedings of ASME 2010, 4th international conference on energy sustainability ES2010, 17–22 May 2010, Phoenix, AZ.

Pöllmann H. Calcium aluminate cements–raw materials, differences, hydration and properties. Rev Mineral Geochem. 2012;74:1–82.

Yuan H-W, Shi Y, Xu Z–Z, Lu C-H, Ni Y-R, Lan X-H. Influence of nano-ZrO2 on the mechanical and thermal properties of high temperature cementitious thermal energy storage materials. Constr Build Mater. 2013;48:6–10.

Yuan H-W, Shi Y, Lu C-H, Xu Z-Z, Ni Y-R, Lan X-H. Influence of polycarboxylate on thermal properties of cementitious solar thermal storage materials. In: International conference on frontiers of energy and environmental engineering. Taylor & Francis–Balkema, Leiden, pp 89–93.

Ltifi M, Guefrech A, Mounanga P, Khelidj A. Experimental study of the effect of addition of nano-silica on the behaviour of cement mortars. Procedia Eng. 2011;10:900–5.

Fernández JM, Duran A, Navarro-Blasco I, Lanas J, Sirera R, Alvarez JI. Influence of nanosilica and a polycarboxylate ether superplasticizer on the performance of lime mortars. Cem Concr Res. 2013;43:12–24.

Senff L, Hotza D, Lucas S, Ferreira VM, Labrincha JA. Effect of nano-SiO2 and nano-TiO2 addition on the rheological behavior and the hardened properties of cement mortars. Mater Sci Eng A. 2012;532:354–61.

Amin MS, El-Gamal SMA, Hashem FS. Effect of nano-magnetite on the hydration characteristics of hardened Portland cement and high slag cement pastes. J Therm Anal Calorim. 2013;112:1253–9.

Mo L-W, Panesar DK. Effects of accelerated carbonation on the microstructure of Portland cement pastes containing reactive MgO. Cem Concr Res. 2012;42:769–77.

Mo L-W, Deng M, Wang A. Effects of MgO-based expansive additive on compensating the shrinkage of cement paste under non-wet curing conditions. Cem Concr Compos. 2012;34:377–83.

Ye Dalun, Jianhua Hu. The handbook of practical inorganic thermodynamic Data. Beijing: Metallurgic Industry Pres; 2002.

Huiwen Yuan Yu, Shi Zhongzi Xu, et al. Effect of nano-MgO on thermal and mechanical properties of aluminate cement composite thermal energy storage materials. Ceram Int. 2014;40(3):4811–7.

Shin AHC, Kodide U. Thermal conductivity of ternary mixtures for concrete pavements. Cem Concr Compos. 2012;34:575–82.

Acknowledgements

The authors would like to express sincere thanks to Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD) and the Independent Research Topics of State Key Laboratory of Materials-Oriented Chemical Engineering (ZK201211) for Financial Support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Shi, Y., Yuan, H., Lu, C. et al. Influence of Cu powders on the properties and characteristics of nano-MgO based aluminate cementitious materials. J Therm Anal Calorim 117, 1285–1292 (2014). https://doi.org/10.1007/s10973-014-3895-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-3895-z