Abstract

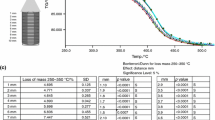

Giomers represent a new concept in restorative dentistry, based on novel pre-reacted glass technology, where special glass-ionomer fillers are included in the resin matrix. A series of resin matrices based on 2,2-bis(2-hydroxy-3-methacryloxypropyl), bis-GMA (phenylpropane), and 1,6-bis(methacryloxy-2-ethoxy-carbonyl-amino)—UDMA (2,4,4-trimethylhexane) as base monomers and triethyleneglycol dimethacrylate (TEGDMA)/2-hydroxyethyl methacrylate (HEMA) as diluting monomers, have been prepared and investigated together with commercial Beautifil II giomer and three adhesives (one commercial and two experimental). The photopyroelectric (PPE) calorimetry in both front and back (BPPE) detection configurations was applied to measure the dynamic thermal parameters of the investigated materials. The BPPE configuration, together with the frequency scanning procedure, was used to directly measure the thermal diffusivity of the primer and the bounding materials, as well as the UDMA/HEMA and TEGDMA/bis-GMA mixtures. The results indicate that the values of the thermal parameters of the materials prepared in our laboratory (6.95 × 10−8 m2 s−1 < α < 12.93 × 10−8 m2 s−1) are close to those of the corresponding commercial materials (11.63 × 10−8 m2 s−1 < α < 12.01 × 10−8 m2 s−1). For the commercially available giomer (Beautifil II), the values of the thermal diffusivity (α = 8.19 × 10−8 m2 s−1) and effusivity (e = 960 W s1/2 m−2 K−1) indicate a good thermal biocompatibility of the material.

Similar content being viewed by others

References

Mandelis A, Zver MM. Theory of the photopyroelectric effect in solids. J Appl Phys. 1985;57:4421–30.

Chirtoc M, Mihailescu G. Theory of the photopyroelectric method for investigation of optical and thermal materials properties. Phys Rev. 1989;B40:9606–17.

Dadarlat D, Bicanic D, Visser H, Mercuri F, Frandas A. Photopyroelectric method for. Determination of thermophysical parameters and detection of phase transitions in fatty acids and triglycerides. Part I: principles, theory and instrumentational concepts. J Am Oil Chem Soc. 1995;72:273–80.

Marinelli M, Mercuri F, Zammit U, Pizzoferrato R, Scudieri F, Dadarlat D. Photopyroelectric study of specific heat, thermal conductivity and thermal diffusivity of Cr2O3 at the Neel transition. Phys Rev. 1994;B49:9523–32.

Dadarlat D, Chirtoc M, Neamtu C, Candea R, Bicanic D. Inverse photopyroelectric detection method. Phys Stat Sol. 1990;121:K231–4.

Dadarlat D, Frandas A. Inverse photopyroelectric detection of phase transitions. Appl Phys. 1993;A56:235–8.

Delenclos S, Dadarlat D, Houriez N, Longuemart S, Kolinsky C, Hadj Sahraoui A. On the accurate determination of thermal diffusivity of liquids by using the photopyroelectric thickness scanning method. Rev Sci Instrum. 2007;78:024902.

Dadarlat D, Neamtu C. High performance photopyroelectric calorimetry of liquids. Acta Chim Slov. 2009;56:225–36.

Dadarlat D. Photopyroelectric calorimetry of liquids. Recent development and applications. Laser Phys. 2009;19:1330–40.

Streza M, Pop MN, Kovacs K, Simon V, Longuemart S, Dadarlat D. Thermal effusivity investigations of solid materials by using the thermal-wave-resonator-cavity (TWRC) configuration. Theory and mathematical simulations. Laser Phys. 2000;19:1340–4.

Mandelis A, Matvienko A. Photopyroelectric thermal-wave cavity devices-10 years later. In: Denis R, editor. Pyroelectric materials and sensors. Trivandrum: Research Signpost; 2007. p. 61–96.

Shen J, Mandelis A. Thermal-wave resonator cavity. Rev Sci Instrum. 1995;66:4999–5005.

Shen J, Mandelis A, Tsai H. Signal generation mechanism, intercavity-gas thermal diffusivity temperature dependence and absolute infrared emissivity measurements in a thermal-wave resonant cavity. Rev Sci Instrum. 1998;69:197–203.

Dadarlat D, Neamtu C, Surducan E, Hadj Sahraoui A, Longuemart S, Bicanic D. Accurate photopyroelectric measurements of thermal diffusivity of (semi)liquids. Instrum Sci Technol. 2002;30:387–96.

Neamtu C, Dadarlat D, Chirtoc M, Hadj Sahraoui A, Longuemart S, Bicanic D. Evidencing molecular associations in binary liquid mixtures via photothermal measurements of thermophysical parameters. Instrum Sci Technol. 2006;34:225–34.

Balderas-Lopez LA, Mandelis A, Garcia JA. Thermal-wave resonator cavity design and measurements of the thermal diffusivity of liquids. Rev Sci Instrum. 2000;71:2933–7.

Balderas-Lopez LA, Mandelis A. Self-consistent photothermal techniques: application for measuring thermal diffusivity in vegetable oils. Rev Sci Instrum. 2003;74:700–2.

Van Landuyt KL, Snauwaert D, de Munk J, Peumans M, Yoshida Y, Poitevin A, Coutinho E, Suzuki K, Lambrechts P, Van Meerbeek P. Systematic review of the chemical composition of contemporary dental adhesives. Biomaterials. 2007;28:3757–85.

Acknowledgements

The authors acknowledge the financial support provided by the Ministry of Education Research and Youth of Romania, through the National Research Programs, PN-II-ID-PCE-2011-3-0036 and PN-II-189/2012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silaghi-Dumitrescu, L., Dadarlat, D., Streza, M. et al. Preparation of a new type of giomers and their thermal characterization by photopyroelectric calorimetry. J Therm Anal Calorim 118, 623–630 (2014). https://doi.org/10.1007/s10973-013-3561-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3561-x