Abstract

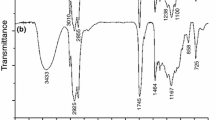

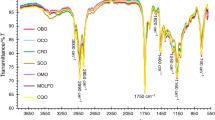

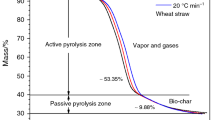

The thermal degradation and corresponding decomposition products of fresh and heat-treated soybean oil were investigated by synchronous thermal analyzer combined with Fourier transform infrared spectrometry and quadrupole mass spectrometry (STA–FTIR–QMS). Two longtime heat-treated soybean oil samples were aforehand prepared by consistently heating the fresh soybean oil for 50 and 100 h, respectively. N2 and simulative air (N2/O2 = 4:1, volume) were used as the thermal reaction gas atmosphere. The results showed that one stage of mass loss appeared in analysis of the all oil samples under N2 atmosphere condition and longtime heat pre-treatment had no effect on the thermal behavior of the soybean oil under N2 atmosphere condition. However, four stages occurred in analysis of both untreated and heat-treated oil samples under the simulative air atmosphere condition. Longtime heat pre-treatment influenced the thermal behavior of the soybean oil in certain extent, which was reflected in the different mass loss values of the four stages. According to the infrared absorption profiles and MS spectra of the released compounds in vapor phase, H2O, CO, CO2, hydrocarbons (such as CH4), and hydroxyl, carbonyl, and carboxyl-contained compounds have been confirmed. Therefore, STA–FTIR–QMS can be suggested as a promising technique for investigating of thermal degradation and monitoring the decomposition products of the evolving substances in edible oils.

Similar content being viewed by others

References

Zhang Q, Saleh ASM, Chen J, Shen Q. Chemical alterations taken place during deep-fat frying based on certain reaction products: a review. Chem Phys Lipids. 2012;165:662–81.

Kulkarni MG, Dalai AK. Waste cooking oil an economical source for biodiesel: a review. Ind Eng Chem Res. 2006;45:2901–13.

Mothé CG, de Castro BCS, Mothé MG. Characterization by TG/DTG/DSC and FTIR of frying and fish oil residues to obtain biodiesel. J Therm Anal Calorim. 2011;106:811–7.

Viola E, Blasi A, Valerio V, Guidi I, Zimbardi F, Braccio G, Giordano G. Biodiesel from fried vegetable oils via transesterification by heterogeneous catalysis. Catal Today. 2012;179:185–90.

Tavares MLA, Queiroz N, Santos IMG, Souza AL, Cavalcanti EHS, Barros AKD, Rosenhaim R, Soledade LEB, Souza AG. Sunflower biodiesel. J Therm Anal Calorim. 2011;106:575–9.

Singh SP, Singh D. Biodiesel production through the use of different sources and characterization of oils and their esters as the substitute of diesel: a review. Renew Sust Energy Rev. 2010;14:200–16.

Baldwin RM, Magrini-Bair KA, Nimlos MR, Pepiot P, Donohoe BS, Hensley JE, Phillips SD. Current research on thermochemical conversion of biomass at the National Renewable Energy Laboratory. Appl Catal B Environ. 2012;115–116:320–9.

Bridgwater AV, Meier D, Radlein D. An overview of fast pyrolysis of biomass. Org Geochem. 1999;30:1479–93.

Maher KD, Bressler DC. Pyrolysis of triglyceride materials for the production of renewable fuels and chemicals. Bioresour Technol. 2007;98:2351–68.

Valliyappan T, Bakhshi NN, Dalai AK. Pyrolysis of glycerol for the production of hydrogen or syn gas. Bioresour Technol. 2008;99:4476–83.

Panwar NL, Kothari R, Tyagi VV. Thermo chemical conversion of biomass—Eco friendly energy routes. Renew Sust Energy Rev. 2012;16:1801–16.

Materazzi S, Gentili A, Curini R. Applications of evolved gas analysis: Part 1: EGA by infrared spectroscopy. Talanta. 2006;68:489–96.

Materazzi S, Gentili A, Curini R. Applications of evolved gas analysis: Part 2: EGA by mass spectrometry. Talanta. 2006;69:781–94.

Materazzi S. Thermogravimetry-infrared spectroscopy (TG-FTIR) coupled analysis. Appl Spectrosc Rev. 1997;32:385–404.

Materazzi S. Mass spectrometry coupled to thermogravimetry (TG-MS) for evolved gas characterization: a review. Appl Spectrosc Rev. 1998;33:189–218.

Materazzi S, Curini R. On-line evolved gas analysis by infrared spectroscopy coupled to thermoanalytical instruments. Appl Spectrosc Rev. 2001;36:1–9.

Materazzi S, Vecchio S. Evolved gas analysis by infrared spectroscopy. Appl Spectrosc Rev. 2010;45:241–73.

Materazzi S, Vecchio S. Evolved gas analysis by mass spectrometry. Appl Spectrosc Rev. 2011;46:261–340.

Alencar JW, Alves PB, Craveiro AA. Pyrolysis of tropical vegetable oils. J Agric Food Chem. 1983;31:1268–70.

Fortes ICP, Baugh PJJ. Pyrolysis-GC/MS studies of vegetable oils from Macauba fruit. Anal Appl Pyrolysis. 2004;72:103–11.

Dandik L, Aksoy HA. Pyrolysis of used sunflower oil in the presence of sodium carbonate by using fractionating pyrolysis reactor. Fuel Process Technol. 1998;57:81–92.

Dandik L, Aksoy HA. Effect of catalyst on the pyrolysis of used oil carried out in a fractionating pyrolysis reactor. Renew Energy. 1999;16:1007–10.

Zhao HY, Cao Y, Orndorff W, Cheng YH, Pan WP. Thermal behaviors of soy biodiesel. J Therm Anal Calorim. 2012;109:1145–50.

Silva HKTA, Chellappa T, Carvalho FC, Silva EFB, Nascimento TA, Araújo ANS, Fernandes VJ Jr. Thermal stability evaluation of methylic biodiesel obtained for different oilseeds. J Therm Anal Calorim. 2011;106:731–3.

Tutunea D. Thermal investigation of biodiesel blends derived from rapeseed oil. J Therm Anal Calorim. 2013;111:869–75.

Teixeira GAA, Maia AS, Rosenhaim R, Santos IMG, Souza AL, Souza AG, Queiroz N. Thermo-oxidative decomposition of biodiesel samples obtained from mixtures of beef tallow, soybean oil, and babassu oil. J Therm Anal Calorim. 2011;106:569–74.

Rodríguez RP, Pérez LG, Alfonso M, Duarte M, Caro R, Galle J, Sierens R, Verhelst S. Thermal behavior of Jatropha curcas oils and their derived fatty acid ethyl esters as potential feedstocks for energy production in Cuba. J Therm Anal Calorim. 2012;109:1005–12.

Nawar WW. Thermal degradation of lipids. J Agric Food Chem. 1969;17:18–21.

de Souza AG, Santos JCO, Conceição MM, Silva MCD, Prasad S. A thermoanalytic and kinetic study of sunflower oil. Braz J Chem Eng. 2004;21:265–73.

Vecchio S, Campanella L, Nuccilli A, Tomassetti MJ. Kinetic study of thermal breakdown of triglycerides contained in extra-virgin olive oil. J Therm Anal Calorim. 2008;91:51–6.

Sahin S, Sumnu SG. Advances in deep-fat frying of foods. London: Taylor & Francis Group; 2009.

Santos JCO, Santos IMG, Conceição MM, Porto SL, Trindade MFS, Souza AG, Prasad S, Fernandes VJ, AraúJo ASJ. Thermoanalytical, kinetic and rheological parameters of commercial edible vegetable oils. J Therm Anal Calorim. 2004;75:419–28.

Dweck J, Sampaio CMS. Analysis of the thermal decomposition of commercial vegetable oils in air by simultaneous TG/DTA. J Therm Anal Calorim. 2004;75:385–91.

Kim TS, Yeo JD, Kim JY, Kim MJ, Lee JH. Determination of the degree of oxidation in highly-oxidised lipids using profile changes of fatty acids. Food Chem. 2013;138:1792–9.

Silverstein RM, Webster FX, Kiemle DJ. Spectrometric identification of organic compounds. 7th ed. Hoboken: Wiley; 2005.

Acknowledgements

The authors would like to heartily thank Prof. Chen Yongmei and her master student Peng Zumao in College of Science of Beijing University of Chemical Technology for their kind help to complete the whole test.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Q., Saleh, A.S.M., Chen, J. et al. Monitoring of thermal behavior and decomposition products of soybean oil. J Therm Anal Calorim 115, 19–29 (2014). https://doi.org/10.1007/s10973-013-3283-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3283-0