Abstract

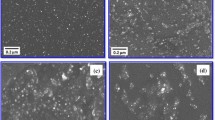

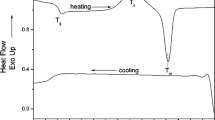

The decomposition kinetics of glycerol diglycidyl ether (GDE)/3,3-dimethylglutaric anhydride/nanoalumina composite have been investigated by thermogravimetry analysis under nonisothermal mode. The activation energy, E a, of the solid-state decomposition process was evaluated using the advanced isoconversional method. From the experimental data, the dependence of conversion on temperature and activation energy was constructed allowing calculating the master plots. Our results showed that the decomposition mechanism at temperatures below 400 °C could be fitted by R2 kinetic model with E a = 143 kJ mol−1. The information about the kinetic parameters based only on thermal degradation data has been used for quick lifetime estimation at different temperatures. The Vyazovkin method was also employed to predict the times to reach α = 0.5 at isothermal mode using the activation energy calculated by the advanced isoconversional approaches. Scanning electron microscopy (SEM) analysis was carried out to investigate the fracture surface morphology. It was revealed from the SEM images that the presence of nanoalumina results in reinforcement of GDE matrix.

Similar content being viewed by others

References

Barral L, Cano J, Lopez J, Lopez-Bueno I, Nogueira P, Abad MJ, Ramrez C. Decomposition behavior of epoxy-resin systems cured by diamines. Eur Polym J. 2000;36:1231–40.

Jablonski AE, Lang AJ, Vyazovkin S. Isoconversional kinetics of degradation of polyvinylpyrrolidone used as a matrix for ammonium nitrate stabilization. Thermochim Acta. 2008;474:78–80.

Santon AF, Polese L, Crespi MS, Ribeiro CA. Kinetic model of poly (3-hydroxybutyrate) thermal degradation from experimental non-isothermal data. J Therm Anal Calorim. 2009;96:287–91.

Vyazovkin S, Wigh CA. Isothermal and nonisothermal reaction kinetics in solids: In search of ways toward consensus. J Phys Chem A. 1997;101:8279–84.

Carrasco F, Pages P. Thermal degradation and stability of epoxy nanocomposites: influence of montmorillonite content and cure temperature. Polym Degrad Stab. 2008;93:1000–7.

Nunez L, Fraga F, Nunez MR, Villanueva M. Thermogravimetric study of the decomposition process of the system BADGE (n = 0)/1,2 DCH. J Appl Polym Sci. 2000;41:4635–41.

Nunez L, Villanueva M, Fraga-Rivas I. Activation energies for the thermodegradation process of an epoxy-diamine system. J Therm Anal Calorim. 2006;83(3):727–33.

Friedman HL. Kinetic and gaseous products of thermal decomposition of polymers. J Macromol Sci A. 1967;1(1):57–79.

Ozawa T. Kinetic analysis of derivative curves in thermal analysis. J Therm Anal. 1970;2(3):301–24.

Flynn JH, Wall LA, Quick A. Direct method for the determination of activation energy from thermogravimetric data. J Polym Sci. 1966;4:323–42.

Doyle CD. Series approximations to the equation of thermogravimetric data. Nature. 1965;207:290–1.

Vyazovkin S, Dollimore D. Linear and nonlinear procedures in isoconversional computations of the activation energy of nonisothermal reactions in solids. J Chem Inform Comput Sci. 1996;36:42–5.

Vyazovkin S. Modification of the integral isoconversional method to account for variation in the activation energy. J Comput Chem. 2001;2(2):178–83.

Sbirrazzuoli N, Vyazovkin S. Learning about epoxy cure mechanisms from isoconversional analysis of DSC data. Thermochim Acta. 2002;388:289–98.

Peterson JD, Vyazovkin S, Wight CA. Kinetics of the thermal and themo-oxidative degradation of polystyrene, poly (propylene). Macromol Chem Phys. 2001;202:775–84.

Gotor FJ, Criado JM, Malek J, Koga N. Kinetic analysis of solid-state reactions: the universality of master plots for analyzing isothermal and nonisothermal experiments. J Phys Chem A. 2000;104:10777–82.

Omrania A, Rostamia AA, Ravaria F, Mashak A. Curing behavior and structure of a novel nanocomposite from glycerol diglycidyl ether and 3, 3-dimethylglutaric anhydride. Thermochim Acta. 2011;517:9–15.

Nunez L, Fraga F, Nunez MR, Villanueva M. Lifetime prediction of the epoxy system badge n = 0/1,2 DCH by thermogravimetric analysis. J Appl Polym Sci. 2000;78:1239–44.

Malek J. The kinetic analysis of nonisothermal data. Thermochim Acta. 1992;200:257–69.

Sestak J, Malek J. Diagnostic limits of phenomenological models of heterogeneous reactions and thermal analysis kinetics. Solid State Ion. 1993;63:245–54.

Vyazovkin S. A unified approach to kinetic processing of nonisothermal data. Int J Chem Kinet. 1996;28:95–101.

Vyazovkin S, Sbirrazzuoli N. Mechanism and kinetics of epoxy-amine cure studied by differential scanning calorimetry. Macromolecules. 1996;29:1867–73.

Vyazovkin S, Sbirrazzuoli N. Isoconversional kinetic analysis of thermally stimulated processes in polymers. Macromol Rapid Commun. 2006;27:1515–32.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Omrani, A., Rostami, A.A. & Ravari, F. Advanced isoconversional and master plot analyses on solid-state degradation kinetics of a novel nanocomposite. J Therm Anal Calorim 111, 677–683 (2013). https://doi.org/10.1007/s10973-011-2154-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-2154-9