Abstract

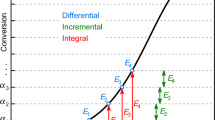

Modeling tradition is reviewed within its historical maturity from Plato do Penrose. Metaphors in nonisothermal kinetics achieved a wide application mostly employing models derived by means of undemanding isothermal descriptions. Geometrical basis of such modeling is revised and discussed in terms of symmetrical and asymmetrical (pentagonal) schemes. The properties of interface (reaction separating line) are found decisive in all cases of heterogeneous kinetics. Application of fractal geometry is accredited, and associated formal kinetic models based on nonintegral power exponents are acknowledged. Typical erroneous beliefs are dealt with showing common kinetic misinterpretation of measured data and associated mathematical manipulability of kinetic equations. The correction of a measured DTA peak is mentioned assuming the effects of heat inertia and temperature gradients.

Similar content being viewed by others

References

Šesták J. Philosophy of non-isothermal kinetics. J Therm Anal. 1979;16:520–603.

Šesták J. Mystery of derivatives in the nonisothermal rate equation. Thermochim Acta. 1985;83:391–4.

Šesták J. Nonisothermal kinetics: art, debate or applied science. J Therm Anal. 1988;33:1263–7.

Šesták J. Plenary lectures: nonisothermal kinetics. In: Wiedemann HG, editors. The proceedings: thermal analysis, conference 3rd ICTA in Davos, Birghausser, Basel; 1972. p. 3–9.

Šesták J. Rationale and fiction of thermochemical kinetics. In: Vitez I, editor. The proceedings: the 34th conference of North American Thermal Analysis Society, Bowling Green; 2006. p. 68–9.

Šestak J. Citation records and some forgotten anniversaries in thermal analysis. J Therm Anal Calorim. 2011 (in press). doi:10.1007/s10973-011-1625-3.

Šatava V. Utilization of thermographic methods for studying reaction kinetics. Silikáty (Prague). 1961;1:68–72. (in Czech).

Proks I. Influence of pace of temperature increase on the quantities important for the evaluation of DTA curves. Silikaty (Prague). 1961;1:114–21 (in Czech).

Šesták J. Temperature effects influencing kinetic data accuracy obtained by thermographic measurements under constant heating. Silikaty (Prague). 1963;7:125–31 (in Czech).

Garn PD. Thermoanalytical methods of investigation. New York: Academic; 1965.

Flynn JH, Wall LA. General treatment of the thermogravimetry of polymers. J Res Nat Bur Stand. 1966;70A:487.

Šesták J. Review of kinetic data evaluation from nonisothermal and isothermal data. Silikáty (Prague). 1967;11:153–90 (in Czech).

Murgulescu JG, Segal E. Reviewing kinetic data evaluations by thermal analysis. St Cerc Chim Tom (Bucharest). 1967;15:261 (in Romanian).

Šesták J. Thermophysical properties of solids: their measurements and theoretical thermal analysis. Amsterdam: Elsevier; 1984 and Teoretičeskij termičeskij analyz. Mir, Moscow; 1987 (in Russian).

Chvoj Z, Šesták J, Tříska A, editors. Kinetic phase diagrams: nonequilibrium phase transitions. Amsterdam: Elsevier; 1991.

Šesták J, editor. Reaction kinetics by thermal analysis. Special issue of Thermochim Acta, vol. 203. Amsterdam: Elsevier; 1992.

Šesták J, Sorai M, editors. Transition phenomena in condensed matter. Special issue of Thermochim Acta, vol. 266. Amsterdam: Elsevier; 1995.

Šesták J. Heat, thermal analysis and society. Nucleus, Hradec Králové; 2004.

Šesták J. Science of heat, thermophysical studies a generalized approach to thermal analysis. Amsterdam: Elsevier; 2005.

Šesták J. Some model classification of geometrical bodies and their development in historical applications. In: Wittwer A, Knut E, Pliska V, Folker G, editors. Approaching scientific knowledge. Zurich: Collegieum Helveticum; 2008. p. 87–91.

Penrose R. Shadow of the mind: approach to the missing science of consciousness. Oxford: Oxford University Press; 1994.

Penrose R. The road to reality: a complete guide to the laws of the Universe. London: Vintage; 2004.

Šesták J, Zámečník J. Can clustering of liquid water be of assistance for better understanding of biological germplasm exposed to cryopreservation. J Therm Anal Calorim. 2007;8:411–9.

Barrow JD. The origin of the universe. Orion, London 1994, impossibility limits of science and science of limits. New York: Vintage; 1999.

Šesták J, Chvoj Z. Irreversible thermodynamics and true thermal dynamics in view of generalized solid-state reaction kinetics. Thermochim Acta. 2002;388:427–31.

Jacobs PWM, Tompkins FC. Classification and theory of solid reactions. In: Garner WE, editor. Chemistry of the solid state. London: Butterworth; 1955. p. 184–212.

Young DA. Decomposition of solids. In: Tompkins FC, editor. Solid and surface kinetics. Oxford: Pergamon; 1966. p. 43–144.

Johnson WA, Mehl RF. Reaction kinetics in processes of nucleation and growth. Trans Am Inst Min Metal Petro Eng. 1939;135:416; reprinted in Metall Mater Trans A. 2010;41A:2713–75.

Hulbert HF. Models for solid-state reactions in powdered compacts: a review. J Br Ceram Soc. 1969;6:11–20.

Brown ME, Dollimore D, Galway AK. Reactions in the solid-state. In: Bamford CH, Tipper CFH, editors. Comprehensive chemical kinetics, vol. 22. Amsterdam: Elsevier; 1980.

Galwey AK, Brown ME. Thermal decomposition of ionic solids. Amsterdam: Elsevier; 1999.

Málek J, Criado JM, Šesták J, Militký J. The boundary conditions for kinetic models. Thermochim Acta. 1989;153:429–32.

Málek J, Mitsuhashi T, Criado JM. Kinetic analysis of solid-state processes. J Mater Res. 2001;16:1862–71.

Šesták J, Málek J. Diagnostic limits of phenomenological models of heterogeneous reactions and thermoanalytical kinetics. Solid State Ion. 1993;63/65:254–9.

Vyazovkin S, Wight CA. Kinetic concepts of thermally stimulated reactions in solids: a view from a historical perspective. Int Rev Phys Chem. 2000;19:45–60.

Mamleev V, Bourbigot S, LeBras M, Duquesne S, Šesták J. Modeling of nonisothermal kinetic mechanism in thermogravimetry. Phys Chem Chem Phys. 2000;2:4708–16.

Koga N, Šesták J. TA kinetics and physical-geometry of the nonisothermal crystallization. Bull Soc Espaňa Cer Vidro. 1992;31:185–9.

Koga N. Physico-geometric kinetics of solid-state reactions as exemplified by thermal dehydration. J Therm Anal. 1997;49:45–56.

Koga N, Tanaka H. A physico-geometric approach to the kinetics of solid-state reactions. Thermochim Acta. 2002;388:41–61.

Khawam A, Flanagan DR. Solid-state kinetic models: basics and mathematical fundamentals. J Phys Chem B. 2006;110:17315–28.

Kimura T, Koga N. Thermal dehydration of monohydrocalcite: overall kinetics and physico-geometrical mechanisms. J Phys Chem A. 2011;115:10491–501.

Koga N, Šesták J, Šimon P. Some fundamental and historical aspects of phenomenological kinetics. In: Šesták J, Šimon P, editors. Thermal analysis of micro-, nano- and non-crystalline materials, Chap. 1. New York: Springer; 2012 (in press). ISBN 978-90-481-3149-5.

Smith CS. Microstructure and geometry. Trans Am Soc Metals. 1953;45:533–75.

Smith CS. Some elementary principles of polycrystalline microstructure. Metal Rev. 1964;9:1–17.

Pfeifer O. Macromolecules and colloidal aggregates—fractal dimension as concealed symmetry of irregular structures. Chimia. 1985;39:120.

Avnir D, Farin D, Pfeifer P. Molecular fractal surfaces. Nature. 1984;308:261–3.

Avnir D. Fractal approach to heterogeneous chemistry. New York: Wiley; 1989.

Kopelman R. Fractal reaction kinetics. Science. 1988;241:620–5.

Schröde M. Fractals, chaos and power laws. New York: Freeman; 1991.

Šesták J. The role of order and disorder in thermal and material sciences part 1: heat and society. J Mining Metal. 2002;38:1–22.

Šesták J. The role of order and disorder in thermal and material sciences part 2: scientific world and new insights. J Mining Metal. 2003;39:1–7.

Glicksman E. Free dendritic growth. Mater Sci Eng. 1984;65:45–54.

Lipton J, Glicksman ME, Kurz W. Dendritic growth into undercooled alloy melts. Mater Sci Eng. 1984;65:57–64.

Roduner E, Cronin L. Nanoscopic materials: size-dependent phenomena. Cambridge: RSC-publ; 2006 & 2007. IBSN 978-1-84755-763-6.

Zhang Z, Li JC, Jiang Q. Modeling for size-dependent and dimension-dependent melting of nanocrystals. J Phys D. 2000;33:2653–6.

Guisbiers G, Buchaillot L. Universal size/shape-dependent law for characteristic temperatures. Phys Lett A. 2009;374:305–8.

Barnard AS. Modelling of nanoparticles: approaches to morphology and evolution—a review. Rep Prog Phys. 2010;73:6502–54.

Elliot RS. Eutectic solidification processing: crystalline and glassy alloys. London: Butterworth; 1989.

Alexander S, Orbach R. Density of states on fractals—fractons. J Phys Lett. 1982;43:L625.

Bonde A, Havlin S. Fractals and disordered systems. Berlin: Springer; 1991.

Peitgen HO, Jurgen H, Saupe D. Chaos and fractals: new frontiers of science. New York: Springer; 1992.

Mandelbrot BB. Gaussian self-similarity, fractals, globallity and 1/f noise. New York: Springer; 2002.

Falcone K. Fractal geometry. Chichester: Wiley; 2003.

Prout EG, Tompkins FC. The thermal decomposition of potassium permanganate. Trans Faraday Soc. 1944;40:488–98.

Ng WL. Thermal decomposition in the solid state. Aust J Chem. 1975;28:1169–78.

Šesták J, Berggren G. Study of the kinetics of the mechanism of solid-state reactions at increasing temperature. Thermochim Acta. 1971;3:1–13.

Málek J, Criado JM. Is the Šesták–Berggren equation a general expression of kinetic models? Thermochim Acta. 1991;175:305–9.

Šimon P. Forty years of Šesták–Berggren equation. Thermochim Acta. 2011. doi:10.1016/j.tca.2011.03.030.

Heal GR. Explanation of the Šestak–Berggren equation. Unpublished communication; 2011.

Yerofeev BV. Reaction rate of processes involving solids with different specific surfaces. In: The proceedings: 4th international symposium reactivity of solids. Amsterdam: Elsevier; 1961. p. 273–82.

Málek J. Crystallization kinetics by thermal analysis. J Therm Anal Calorim. 1999;56:763–9.

Málek J. Kinetic analysis of crystallization processes in amorphous materials. Thermochim Acta. 2000;355:239–53.

Šesták J, Kratochvil. Rational approach to thermodynamic processes and constitutive equations in kinetics. J Therm Anal. 1973;5:193–201.

Šesták J. Thermodynamic basis for the theoretical description and correct interpretation of thermoanalytical experiments. Thermochim Acta. 1979;28:197–227.

Holba P, Šesták J. Kinetics with regard to the equilibrium of processes studied by non-isothermal techniques. Zeit physik Chem NF. 1972;80:1–20.

Šesták J. Key lecture: integration of nucleation-growth equation when considering non-isothermal regime and shared phase separation. In: Dolimore D, editor, The 2nd ESTAC (Europ. symp. on thermal analysis) in proc. thermal analysis, Heyden, London; 1981. p. 115–20.

Hiller R, editor. Application of fractional calculus in physics. River Edge: World Science; 2000.

Milledr KS, Ross B. Introduction to the fractional calculus and fractional differential equations. New York: Wiley; 1993.

Fleschinger MF, Zaslavsky GM, Klaufter J. Strange kinetics. Nature. 1993;363:31–3.

Galwey AK, Brown ME. Application of the Arrhenius equation to solid-state kinetics: can this be justified? Thermochim Acta. 2002;386:91–8.

Galwey AK. Eradicating erroneous Arrhenius arithmetic. Thermochim Acta. 2003;399:1–29.

Galwey AK. Theory of solid-state thermal decomposition: scientific stagnation or chemical catastrophe? An alternative approach apprised and advocated. Unpublished communication; 2011.

L’vov BV. Thermal decomposition of solids and melts: a new thermochemical approach to the mechanism, kinetics and methodology. Berlin: Springer; 2007.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29:1702–6.

Šesták J. On the applicability of π(x)-function to the determination of reaction kinetics under nonisothermal conditions. Thermochim Acta. 1971;3:150–4.

Henderson DW. Experimental analysis of nonisothermal transformations involving nucleation and growth. J Therm Anal. 1979;15:325–31.

Kemeny J, Šesták J. Comparison of crystallization kinetic theories derived by isothermal and nonisothermal methods. Thermochim Acta. 1987;110:113–9.

Broido A, Williams AF. Use of asymptotic analysis of the large activation energy limit to compare various graphical methods of treating TG data. Thermochim Acta. 1970;6:245–53.

Moynihan CT. Correlation between the width of the glass-transition region and the temperature dependence of glass viscosity. J Am Ceram Soc. 1993;76:1081–8.

Šesták J. Applicability of DTA to study of crystallization kinetics of glasses. Phys Chem Glass. 1974;15:137–40.

Christian JW. Theory of transformations in metals and alloys. Oxford: Pergamon; 1975.

Málek J, Šesták J, Rouquerol F, Rouquerol J, Criado JM, Ortega A. Possibilities of two non-isothermal procedures (temperature-and/or rate-controlled) for kinetic studies. J Therm Anal. 1992;38:71–87.

Criado JM, Gotor FJ, Ortega A, Real C. New method of CRTA-application to discrimination of the kinetic models of solid-state reactions. Thermochim Acta. 1992;199:235–8.

Koga N, Tanak H, Criado JM. Kinetic analysis of inorganic solid-state reactions by CRTA. Netsu Sokutei (Jap J Therml Anal). 2000;27:128–40.

Koga N. A review of the emutual dependence of Arrhenius parameters evaluated by the thermoanalytical study of solid-state reactions: the kinetic compensation effect. Thermochim Acta. 1994;244:1–10.

Koga N. Kinetic analysis of thermoanalytical data by extrapolating to infinite temperature. Thermochim Acta. 1995;258:145–9.

Šesták J, Mareš JJ, Krištofik J, Hubík P. True physical meaning of the so called kinetic compensation effect. Glastech Ber Glass Sci Technol. 2000;73(C1):104–8.

Galwey AK, Mortimer M. Compensation effects and compensation defects in kinetic and mechanistic interpretations of heterogeneous chemical reactions. Int J Chem Kinet. 2006;38:464–73.

Šesták J, Strnad Z. Simulation of DTA crystallization peak on basis of nucleation-growth curves determined by optical microscopy. In: Gotz J, editor, The proceedings: XI inter. congress on glass, DT CVTS, Vol. II, Prague; 1977. p. 249–61.

Málek J, Zmrhalová Z, Barták J, Honcová P. A novel method to study crystallization of glasses. Thermochim Acta. 2010;511:67–73.

Málek, J, Shánělová J. Crystallization kinetics in amorphous materials studied by means of calorimetry, microscopy and dilatometry. In: Šesták J, Šimon P, editors. Thermal analysis of micro-, nano- and non-crystalline materials, Chap. 14. New York: Springer; 2012 (in press). ISBN 978-90-481-3149-5.

Dubaj T, Cibulková Z, Šimon P. Justification of the use of non-Arrhenian temperature functions, prepared for publication 2012.

Šimon P. Single-step kinetics approximation employing non-Arrhenius temperature functions. J Therm Anal Calorim. 2005;79:703.

Šimon P. The single-step approximation: attributes, strong and weak sides. J Therm Anal Calorim. 2007;88:709–15.

Serra R, Nomen R, Sempere J. Non-parametric kinetics: a new method for kinetic study. J Therm Anal Calorim. 1998;52:933.

Vyazovkin S. Model-free kinetics: staying free of multiplying entities without necessity. J Therm Anal Calorim. 2006;83:45.

Šesták J, Holba P. Theory of thermoanalytical methods based on the indication of enthalpy changes. Silikáty (Prague). 1976;29:83–8. (in Czech).

Šesták J, Holba P, Lombardi G. Quantitative evaluation of thermal effects: theoretical basis of DTA/DSC. Annali di Chimica (Roma). 1977;67:73–9.

Nevřiva M, Holba P, Šesták J. Utilization of DTA for the determination of transformation heats. Silikaty (Prague). 1976;29:33–8. (in Czech).

Holba P, Nevřiva M, Šesták J. Analysis of DTA curve and related calculation of kinetic data using computer technique. Thermochim Acta. 1978;23:223–31.

Holba P, Šesták J, Sedmidubsky D. Heat transfer and phase transition at DTA experiments. In: Šesták J, Šimon P, editors. Thermal analysis of micro-, nano- and non-crystalline materials, Chap. 4. New York: Springer; 2012 (in press). ISBN 978-90-481-3149-5.

Höhne GWH, Hemminger W, Flammersheim HJ. Differential scanning calorimetry. Dordrecht: Springer; 2003.

Brown ME, Gallagher PK, editors. Handbook of thermal analysis and calorimetry. Amsterdam: Elsevier; 2008.

Gabbott G, editor. Principles and application of thermal analysis. Oxford: Blackwell; 2008.

Boerio-Goates J, Callen JE. Differential thermal methods. In: Rossiter BW, Beatzold RC, editors. Determination of thermodynamic properties. New York: Wiley; 1992. p. 621–718.

Acknowledgements

The results were developed within the CENTEM project, reg. no. CZ.1.05/2.1.00/03.0088 that is co-funded from the ERDF within the OP RDI program of the Ministry of Education, Youth and Sports. I feel also indebted to my scientific friends, coworkers, and uppermost kineticists: late Joseph H. Flynn (Bethesda), Jerry Czarnecki (Fullerton), Klaus Heide (Jena), Pavel Holba (Prague), Nobuyoshi Koga (Hiroshima), Jiří Málek (Pardubice), Eugéne Segal (Bucharest), Peter Šimon (Bratislava), Donald R. Uhlmann (Tucson) and Živan Živkovič (Serbian Bor).

Author information

Authors and Affiliations

Corresponding author

Additional information

Devoted to the 90th birth anniversary (July 2012) of Vladimir Šatava (Prague) and also written on the occasion of passing away (October 2011 at the age 85) of Ivo Proks (Bratislava) both the foremost pioneers in the fields of thermodynamics and thermal analysis, to whom this paper is dedicated.

Rights and permissions

About this article

Cite this article

Šesták, J. Rationale and fallacy of thermoanalytical kinetic patterns. J Therm Anal Calorim 110, 5–16 (2012). https://doi.org/10.1007/s10973-011-2089-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-2089-1