Abstract

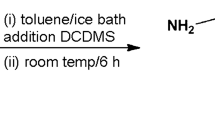

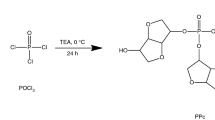

A novel silicon-containing trifunctional cycloaliphatic epoxide resin tri(3,4-epoxycyclohexylmethyloxy) phenyl silane (TEMPS) was synthesized and characterized by FTIR, 1H NMR, 13C NMR, and 29Si NMR spectroscopic analysis. A series of flame-retardant formulations by blending TEMPS with a commercial epoxide resin DGEBA (EP828) in different ratios were prepared, and exposed to a medium pressure lamp to form the cured films in the presence of diaryliodonium hexafluorophosphate salt as a cationic photoinitiator. The thermal degradation behaviors of the cured films were evaluated by thermogravimetric analysis. The char yields under nitrogen and air atmospheres increased along with the TEMPS content. The limiting oxygen index (LOI) value increased from 22 for EP828 to 30 for TEMPS80, demonstrating the improved flame retardancy. The data from the dynamic mechanical thermal analysis showed that TEMPS had good miscibility with EP828. The T s and T g both decreased from 93 and 138 to 78 and 118 °C, respectively. The crosslinking density (ν e) increased along with the TEMPS content. The mechanical property measurements indicated that the addition of TEMPS led to a decrease in the tensile strength and an increase in the elongation-at-break.

Similar content being viewed by others

References

Calbo LJ. Handbook of coatings additives. New York: Marcel Dekker; 1986.

May CA, editor. Epoxy resins chemistry and technology. New York: Marcel Dekker, 1988.

Lin SC, Pearce PM. High-performance thermosets. New York: Hanser; 1994.

Sen AK, Mukheriee B, Bhattacharya AS, Sanghi LK, De PP, Bhowmick K. Preparation and characterization of low-halogen and nonhalogen fire-resistant low-smoke (frls) cable sheathing compound from blends of functionalized polyolefins and PVC. J Appl Polym Sci. 1991;43:1673–84.

Hsiue GH, Wang WJ, Chang FC. Synthesis, characterization, thermal and flame-retardant properties of silicon-based epoxy resins. J Appl Polym Sci. 1999;73:1231–8.

Hsiue GH, Liu YL, Tsiao J. Phosphorus-containing epoxy resins for flame retardancy V: synergistic effect of phosphorus–silicon on flame retardancy. J Appl Polym Sci. 2000;78:1–7.

Wang WJ, Perng LH, Hsiue GH, Chang FC. Characterization and properties of new silicone-containing epoxy resin. Polymer. 2000;41:6113–22.

Abad MJ, Barral L, Fasce DP, Williams RJJ. Epoxy networks containing large mass fractions of a monofunctional polyhedral oligomeric silsesquioxane (POSS). Macromolecules. 2003;36:3128–35.

Mecado LA, Reina JA, Galià M. Flame retardant epoxy resins based on diglycidyloxymethylphenylsilane. J Polym Sci A: Polym Chem. 2006;44:5580–7.

Mercado LA, Galià M, Reina JA. Silicon-containing flame retardant epoxy resins: synthesis, characterization and properties. Polym Degrad Stab. 2006;91:2588–94.

Spontón M, Mercado LA, Ronda JC, Galià M, Cádiz V. Preparation, thermal properties and flame retardancy of phosphorus-and silicon-containing epoxy resins. Polym Degrad Stab. 2008;93:2025–31.

Hsiue GH, Wei HF, Shiiao SJ, Kuo WJ, Sha YA. Chemical modification of dicyclopentadiene-based epoxy resins to improve compatibility and thermal properties. Polym Degrad Stab. 2001;73:309–18.

Decker C. Photoinitiated crosslinking polymerisation. Prog Polym Sci. 1996;21:593–650.

Fieberg A, Reis O. UV curable electrodeposition systems. Prog Org Coat. 2002;45:239–47.

Wu S, Sears MT, Soucek MD, Simonsick WJ. Synthesis of reactive diluents for cationic cycloaliphatic epoxide UV coatings. Polymer. 1999;40:5675–86.

Decker C, Viet TNT, Decker D, Weber-Koehl E. UV-radiation curing of acrylate/epoxide systems. Polymer. 2001;42:5531–41.

Wang HL, Liu JH, Xu SP, Shi WF. Preparation and film properties of tri(3,4-epoxycyclohexylmethyl) phosphate based cationically UV curing coatings. Prog Org Coat. 2009;65:263–8.

Kanai H, Sullivan V, Auerback A. Impact modification of engineering thermoplastics. J Appl Polym Sci. 1994;53:527–41.

Hill LW. Structure/property relationships of thermoset coatings. J Coat Technol. 1992;64:29–42.

Acknowledgements

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (No. 50633010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, Xe., Shi, W. Synthesis and thermal properties of silicon-containing epoxy resin used for UV-curable flame-retardant coatings. J Therm Anal Calorim 103, 303–310 (2011). https://doi.org/10.1007/s10973-010-1053-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-1053-9