Abstract

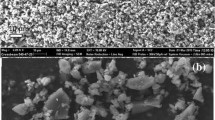

Phase change nanocomposites were prepared by dispersing γ-Al2O3 nanoparticles into melting paraffin wax (PW). Intensive sonication was used to make well dispersed and homogeneous composites. Differential scanning calorimetric (DSC) and transient short-hot-wire (SHW) method were employed to measure the thermal properties of the composites. The composites decreased the latent heat thermal energy storage capacity, L s, and melting point, T m, compared with those of the PW. Interestingly, the composites with low mass fraction of the nanoparticles, have higher latent heat capacity than the calculated latent heat capacity value. The thermal conductivity of the nanocomposites was enhanced and increased with the mass fraction of Al2O3 in both liquid state and solid state.

Similar content being viewed by others

References

Sari A, Alkan C, Karaipekli A, Önal A. Preparation, characterization and thermal properties of styrene maleic anhydride copolymer (SMA)/fatty acid composites as form stable phase change materials. Energy Convers Manage. 2008;49:373–80.

Wang J, Xie H, Xin Z. Thermal properties of paraffin based composites containing multi-walled carbon nanotubes. Thermochim Acta. 2009;488:39–42.

Sari A, Karaipekli A. Preparation and thermal properties of capric acid/palmitic acid eutectic mixture as a phase change energy storage material. Mater Lett. 2008;62:903–6.

Dimaano MNR, Watanabe T. Performance investigation of the capric and lauric acid mixture as latent heat energy storage for a cooling system. Sol Energy. 2002;72:205–15.

Sari A. Thermal characteristics of a eutectic mixture of myristic and palmitic acids as phase change material for heating applications. Appl Therm Energy. 2003;23:1005–17.

Karaipekli A, Sari A, Kaygusuz K. Thermal conductivity improvement of stearic acid using expanded graphite and carbon fiber for energy storage applications. Renew Energy. 2007;32:2201–10.

Fukai J, Kanou M, Kodama Y, Miyatake O. Thermal conductivity enhancement of energy storage media using carbon fibers. Energy Convers Manage. 2000;41:1543–56.

Lee J, Mudawar I. Assessment of the effectiveness of nanofluids for single-phase and two-phase heat transfer in micro-channels. Int J Heat Mass Transf. 2007;50:452–63.

Kim J-K, Jung JY, Kang YT. The effect of nano-particles on the bubble absorption performance, in a binary nanofluid. Int J Refrig. 2006;29:22–9.

Heris SZ, Etemad SG, Esfahany MN. Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int Commun Heat Mass Transf. 2006;33:529–35.

Sari A, Karaipekli A. Thermal conductivity and latent heat thermal energy storage characteristics of paraffin/expanded graphite composite as phase change material. Appl Therm Energy. 2007;27:1271–7.

Xie H, Gu H, Fujii M, Zhang X. Short hot wire technique for measuring thermal conductivity and thermal diffusivity of various materials. Meas Sci Technol. 2006;17:208–14.

Wang J, Xie H, Xin Z. Thermal properties of heat storage composites containing multi-walled carbon nanotubes. J Appl Phys. 2008;104(113537):1–5.

Ye X, Sha J, Jiao Z, et al. Size effect on structure and infrared behavior in nanocrystalline magnesium oxide. Nano-Struct Mater. 1997;8(7):945–51.

Zheng C, Zhang X, Zhang J, Liao K. Preparation and characterization of VO2 nanopowders. J Solid State Chem. 2001;156:274–80.

Wang Y, Suryanarayana C, An L. Phase transformation in nanometer-sized γ-Al2O3 by mechanical milling. J Am Ceram Soc. 2005;3:780–3.

Kumar DH, Patel HE, Kumar VRR, Sundararajan T, Pradeep T, Das SK. Model for heat conduction in nanofluids. Phys Rev Lett 2004;93(14):144301,1–4.

Huxtable ST, Cahill DG, Shenogin S, Xue L, Ozisik R, Barone P, et al. Effect of chemical functionalization on thermal transport of carbon nanotube composites. Nat Mater. 2003;2:731–4.

Papanikolaou N. Nonequilibrium radiation dosimetry. J Phys Condens Matter. 2008;20(135201):1–6.

Zhong HL, Lukes JR. Interfacial thermal resistance between carbon nanotubes: molecular dynamics simulations and analytical thermal modeling. Phys Rev B. 2006;74(125403):1–10.

Fu S-Y, Mai Y-W. Thermal conductivity of misaligned short-fiber-reinforced polymer composites. J Appl Poly Sci. 2003;88:1497–505.

Acknowledgements

This work was supported by National Science Foundation of China (50876058, 20876042), New Century Excellent Talents in University (NCET-10-883), and the Program for Professor of Special Appointment (Eastern Scholar) at Shanghai Institutions of Higher Learning.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Xie, H., Li, Y. et al. PW based phase change nanocomposites containing γ-Al2O3 . J Therm Anal Calorim 102, 709–713 (2010). https://doi.org/10.1007/s10973-010-0850-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-0850-5