Abstract

The ceramic industry uses enormous amounts of energy to produce products at high temperatures. Energy-saving measures based on sintering process improvements are examined.

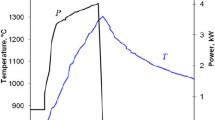

Oxide ceramics were irradiated by two different methods during microwave sintering: intermittent use of the same high power levels (time-control method) and continuous use of lower, increasing levels of power (power-control method). We found that: 1) the power consumption and efficiency of the time-control method were lower than those of the power-control method; 2) the power-control method gave more precise control of temperature under our experimental conditions; 3) sample densification did not differ greatly between the two methods; and 4) grain growth did not differ greatly between the two methods.

Similar content being viewed by others

References

WH Sutton (1989) J. Am. Ceram. Soc. Bull. 68 376 Occurrence Handle1:CAS:528:DyaL1MXhtF2lurk%3D

JD Katz (1992) Annual Review of Materials 22 153 Occurrence Handle1:CAS:528:DyaK38XlvFKlt7Y%3D

C Saltiel Z Fathi WH Sutton ( 1995) Mechanical Engineering 117 102

DE Clark WH Sutton (1996) Annual Review of Materials 26 299 Occurrence Handle1:CAS:528:DyaK28XkvFGmsLw%3D

KG Ayappa (1997) Rev. Chem. Eng. 13 1 Occurrence Handle1:CAS:528:DyaK2sXlvV2rsb4%3D

WC Lee KS Kuo IN Lin (1999) Ferroelectrics 231 237

A Birnboim D Gershon J Calame A Birman Y Carmel J Rodgers B Levush YV Bykov AG Eremeev VV Holoptset D Dadon PL Martin M Rosen ( 1988) J. Am. Ceram. Soc. 81 1493

LM Levinson HR Philipp (1986) J. Am. Ceram. Soc. Bull. 65 639 Occurrence Handle1:CAS:528:DyaL28XhvFOksrg%3D

TK Gupta ( 1990) J. Am. Ceram. Soc. 73 1817 Occurrence Handle10.1111/j.1151-2916.1990.tb05232.x

I Lin W Lee K Liu H Cheng M Wu (2001) J. Eur. Ceram. Soc. 21 2085 Occurrence Handle1:CAS:528:DC%2BD3MXms12itrs%3D

JH Booske RF Cooper SA Freeman (1997) Mater. Res. Innov. 1 77 Occurrence Handle10.1007/s100190050024 Occurrence Handle1:CAS:528:DyaK2sXntFyqs7o%3D

JP Cheng D Agrawal YJ Zhang R Roy (2002) Mater. Lett. 56 587 Occurrence Handle1:CAS:528:DC%2BD38XnvVyltb8%3D

KH Brosnan GL Messing DK Agrawal (2003) J. Am. Ceram. Soc. 86 1307 Occurrence Handle1:CAS:528:DC%2BD3sXmt1Gitr8%3D

M Mizuno S Obata S Takayama S Ito N Kato T Hirai M Sato (2004) J. Eur. Ceram. Soc. 24 387 Occurrence Handle10.1016/S0955-2219(03)00217-6 Occurrence Handle1:CAS:528:DC%2BD3sXpt1Khsbo%3D

HY Chang KS Liu IN Lin (1995) J. Appl. Phys. 78 423 Occurrence Handle1:CAS:528:DyaK2MXmsFWltLY%3D

Y Ma E Vileno SL Suib PK Dutta (1997 ) Chem. Mater. 9 3023 Occurrence Handle10.1021/cm970371n Occurrence Handle1:CAS:528:DyaK2sXnsVCmt70%3D

OP Thakur C Prakash DK Agrawal (2002) J. Ceram. Proc. Res. 3 75.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yasuoka, M., Nishimura, Y., Nagaoka, T. et al. Influence of different methods of controlling microwave sintering . J Therm Anal Calorim 83, 407–410 (2006). https://doi.org/10.1007/s10973-004-6725-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-004-6725-x