Abstract

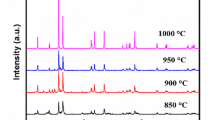

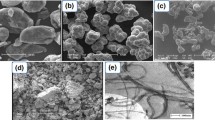

Scandate cathode made out of tungsten nanoparticles have several advantages such as high current density, uniform emission, and long life over conventional cathode. Fabrication of porous tungsten pellet out of tungsten nanoparticles by pressing and sintering is a critical challenge. Cold pressing followed by sintering of nanoparticles results shrinkage of pellet size and uncontrolled porosity, which motivate us to work on sintering of nanoparticle. A new chemical synthesis approach was adopted for precisely controlling the powder particle parameters. The present technology relates to the preparation of an ultra-fine nano-scandate powder using chemical route, dissolving tungsten, and rhenium powder in special solvent under ultra-agitation, wherein the other constituents (such as Ba, Ca, Sc, and alumina) are uniformly distributed throughout the powder. Dissolving tungsten and rhenium in the solution, and further sol–gel process, resulted in the formation of spherical shaped particles. Nanoparticles were characterized using: (1) X-ray diffraction (XRD) for phase purity of powder, (2) Field Emission Scanning Electron Microscopy (FE-SEM) for particle size and distribution, (3) Scanning Electron Microscopy (SEM) to study the surface micro-features such as pore dimension and pore distribution and (d) Energy Dispersive Analysis of X-rays (EDAX) for elemental composition. The results showed that the powder has uniform grain size with an average particle diameter of ~100 nm. In this proposed work, rhenium has been co-doped with scandia doped tungsten nanoparticles in order to improve shrinkage. Addition of rhenium in scandia doped tungsten nanoparticles showed about 10% less shrinkage compared with scandia doped tungsten nanoparticle.

Highlights

-

A novel synthesis approach for scandia doped rhenium–tungsten mixed nanoparticles using a sol–gel method was developed by dissolving tungsten and rhenium powder in hydrogen peroxide.

-

The characterization result showed that the complete formation of the spherical shape, homogeneously mixed, phase pure nanoparticle with an average diameter of 100 nm without any contamination by other materials.

-

Shrinkage effect of tungsten pellet made out of nanoparticles was reduced.

Similar content being viewed by others

References

Benford J, Swegle JA, Schamiloglu E, Institute of Physics (Great Britain) (2007). High power microwaves. Bristol: Taylor & Francis

Gold SH, Nusinovich GS (1997) Review of high-power microwave source research. Rev Sci Instrum 68:3945–3974

Li J et al. (2016) An X band 5-way multiplexer for high power microwave combination. In: Proceedings of the Progress in Electromagnetic Research Symposium (PIERS), Shanghai, p 4459–4461

Green MC (2008) Cathode technology overview: current status and future directions. In: Proceedings of the IEEE International Vacuum Electronics Conference. Monterey, CA: IEEE, p 3–4

Li L, Wang J, Wang Y (2009) Generation of high-current-density sheet electron beams. IEEE Electron Device Lett 30:228–230

Shih A, Yater J, Hor C (2005) Ba and BaO on W and on Sc2O3 coated W. Appl Surf Sci 242:35–54

Yamamoto S et al. (1984) Study of metal film coating on Sc2O3 mixed matrix impregnated cathodes. Appl Surf Sci 17:517–529

Yamamoto S et al. (1984) Electron emission properties and surface atom behavior of impregnated cathodes with rare earth oxide mixed matrix base metals. Appl Surf Sci 20:69–83

Yamamoto S et al. (1986) Electron emission properties and surface atom behavior of an impregnated cathode coated with tungsten thin film containing Sc2O3. Jpn J Appl Phys 25(7R):971

Zhao J, Li N, Li J, Barnett LR, Banducci M, Gamzina D, Munir ZA, Luhmann NC (2011) High current density and long life Nanocomposite scandate dispenser cathode fabrication. IEEE Trans Electron Devices 58:1221–1228

Schietrum G, Caryotakis C, Luhmann N, Wang Y, Li J,Miram G, Vancil B (2006) 100 A/cm2 Tungsten-Scandate Nanopowder Thermionic Cathode Testing at SLAC. In: Multidisciplinary University Research Initiative Annual Review, Monterey, CA

Booske JH (2008) Plasma physics and related challenge of millimeter-wave-to-terahertz and high power microwave generation. Phys Plasmas 15:055502

Barik RK, Singh AK, Shukla. SK, Singh TP, Raju RS, Park GS (2016) Development of nanoparticle-based high current density cathode for THz devices application. IEEE Trans ED 63:1715–1721

Shukla SK, Singh AK, Singh TP, Saini SK, Poonia RK, Raju RS, Barik RK (2016) Study and Development of Yttrium-Doped Nanoscandate Cathode for High-Power VEDs. IEEE Trans Electron Devices 63

Glazkova EA, Pervikov AV, Rodkevich NG, Apkaryan AS, Yu S. Muzhetskaya (2018) Sintering of W-Ni-Fe powders produced byelectrical explosion of wires. In: AIP Conference Proceedings, 2053, Ekaterinburg, Russia: AIP Conference Proceedings, p 4975–4980

Sahin Y (2014) Recent progress in processing of tungsten heavy alloys. J Powder Technol 764306:1–22

Webb JA, Charit I, Sparks C, Butt PD, Frary M, Carroll M (2011) SPS fabrication of tungsten-rhenium alloys in support of NTR fuels development. In: Proceedings of Nuclear and Emerging Technologies for Space 2011. Albuquerque: Idaho National Laboratory, NM, p 3274

Nokhrin AV et al. (2017) Spark Plasma Sintering of high-strength ultrafine-grained tungsten carbide. IOP Conference Series: Materials Science and Engineering, vol 218, p 012012

Tolochko OV, Klimova OG, Ordnian SS, Cheong D-I, Kim YM (2009) Effects of tungsten nanoparticles additions on the densification of micron size tungsten powder. Rev Adv Mater Sci 21:192–199

Aravinth S, Sankar B, Chakravarthy SR, Sarathi R (2011) Generation and characterization of nano tungsten oxide particles by wire explosion process. Mater Charact 62:248–255

Sarathi R, Sindhu TK, Chakravarthy SR, Sharma A, Nagesh KV (2009) Generation and characterization of nano-tungsten particles formed by wire explosion process. J Alloy Compd 475:658–663

Kwon YS, Gromov AA, Ilyin AP, Ditts AA, Kim JS, Park SH (2004) Features of passivation, oxidation and combustion of tungsten nano-powders by air. Int J Refractory Met Hard Mater 22:235–241

Murugan K, Chandrasekhar SB, Joardar J (2011) Nanostructured α/β-tungsten by reduction of WO3 under microwave plasma. Int J Refractory Met Hard Mater 29:128–133

Zhang H, Bai L, Hu P, Yuan F, Li J (2012) Single-step pathway for the synthesis of tungsten nanosized powders by RF induction thermal plasma. Int J Refractory Met Hard Mater 31:33–38

Wu C (2011) Preparation of ultrafine tungsten powders by in-situ hydrogen reduction of nano-needle violet tungsten oxide. Int J Refractory Met Hard Mater 29:686–691

Sahoo PK, Kamal SSK, Premkumar M, Jagadeesh TK, Sreedhar B, Singh AK, Srivastava SK, Chandra Sekhar K (2009) Synthesis of tungsten nanoparticles by solvothermal decomposition of tungsten hexacarbonyl. Int J Refractory Met Hard Mater 27:784–791

Wang Y, Wang J, Liu W, Li L, Wang Y, Zhang X (2009) Correlation between emission behavior and surface features of scandate cathodes. IEEE Trans Electron Devices 56:776–785

Barik RK, Bera A, Tanwar AK, Baek IK, Min SH, Kwon OJ, Lee WS, Park G-S (2003) A novel approach to synthesis of scandia-doped tungsten nano-particles for high-current-density cathode applications. Int J Refractory Met Hard Mater 38:60–66

Shukla SK, Barik RK, Raju RS (2016) Synthesis of Re and Sc doped impregnant mixed tungsten nano-powder for application of Cathode in THz-region. Indian Patent 201611005494, 17 Feb 2016

Charit I, Butt DP, Frary M, Carroll MC (2012) Fabrication of tungsten-rhenium cladding materials via spark plasma sintering for ultra high temperature reactor applications. Final Rep 09-775:1–73

Schindelin J, Arganda-Carreras I, Frise E et al. (2012) “Fiji: an open-source platform for biological-image analysis”. Nat methods 9:676–682

Klopp WD (1968) Review of ductilizing of group VIA elements by rhenium and other solutes. NASA TN D-4955, Lewis Research Center Report

Nieh TG, Wadsworth J (1993) Materials research society, Boston, MA, USA

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shukla, S.K., Singh, A.K. & Barik, R.K. Synthesis of Rhenium–Scandia doped tungsten nanoparticles for shrinkage investigation. J Sol-Gel Sci Technol 95, 384–392 (2020). https://doi.org/10.1007/s10971-020-05253-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05253-8