Abstract

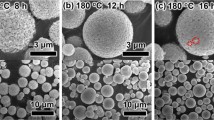

Herein, porous Li3V2(PO4)3/C microspheres made of nanoparticles are obtained by a combination of sol spray-drying and subsequent-sintering process. Beta-cyclodextrin serves as a special chelating agent and carbon source to obtain carbon-coated Li3V2(PO4)3 grains with the size of ca. 30–50 nm. The unique porous structure and continuous carbon skeleton facilitate the fast transport of lithium ion and electron. The Li3V2(PO4)3/C microspheres offer an outstanding electrochemical performance, which present a discharge capacity of 122 mAh g−1 at 2 C with capacity retention of 96% at the end of 1000 cycles and a high-rate capacity of 113 mAh g−1 at 20 C in the voltage window of 3.0–4.3 V. Moreover, the Li3V2(PO4)3/C microspheres also give considerable cycling stability and high-rate reversible capacity at a higher end-of-charge voltage of 4.8 V.

Similar content being viewed by others

References

Rui X, Yan Q, Skyllas-Kazacos M, Lim TM (2014) Li3V2(PO4)3 cathode materials for lithium-ion batteries: a review. J Power Sources 258:19–38

Zhang L, Xiang H, Li Z, Wang H (2012) Porous Li3V2(PO4)3/C cathode with extremely high-rate capacity prepared by a sol–gel-combustion method for fast charging and discharging. J Power Sources 203:121–125

Ni J, Zhang L, Fu S, Savilov SV, Aldoshin SM, Lu L (2015) A review on integrating nano-carbons into polyanion phosphates and silicates for rechargeable lithium batteries. Carbon 92:15–25

Sun HB, Zhang LL, Yang XL, Liang G, Li Z (2016) Investigation of Co-incorporated pristine and Fe-doped Li3V2(PO4)3 cathode materials for lithium-ion batteries. Dalton Trans 45:15317–15325

Cheng Y, Feng K, Zhou W, Zhang H, Li X, Zhang H (2015) A Bi-doped Li3V2(PO4)3/C cathode material with an enhanced high-rate capacity and long cycle stability for lithium ion batteries. Dalton Trans 44:17579–17586

Liu C, Massé R, Nan X, Cao G (2016) A promising cathode for Li-ion batteries: Li3V2(PO4)3. Energy Storage Mater 4:15–58

Kim S, Song J, Sambandam B, Kim S, Jo J, Park S, Baek S, Kim J (2017) One step pyro-synthesis process of nanostructured Li3V2(PO4)3/C cathode for rechargeable Li-ion batteries. Mater Today Commun 10:105–111

Secchiaroli M, Nobili F, Tossici R, Giuli G, Marassi R (2015) Synthesis and electrochemical characterization of high rate capability Li3V2(PO4)3/C prepared by using poly(acrylic acid) and D-(+)-glucose as carbon sources. J Power Sources 275:792–798

Rui XH, Li C, Chen CH (2009) Synthesis and characterization of carbon-coated Li3V2(PO4)3 cathode materials with different carbon sources. Electrochim Acta 54:3374–3380

Wang L, Tang Z, Ma L, Zhang X (2011) High-rate cathode based on Li3V2(PO4)3/C composite material prepared via a glycine-assisted sol-gel method. Electrochem Commun 13:1233–1235

Yang CC, Kung SH, Lin SJ, Chien WC (2014) Li3V2(PO4)3/C composite materials synthesized using the hydrothermal method with double-carbon sources. J Power Sources 251:296–304

Liu Q, Ren L, Cong C, Ding F, Guo F, Song D, Guo J, Shi X, Zhang L (2016) Study on Li3V2(PO4)3/C cathode materials prepared using pitch as a new carbon source by different approaches. Electrochim Acta 187:264–276

Rui XH, Li C, Liu J, Cheng T, Chen CH (2010) The Li3V2(PO4)3/C composites with high-rate capability prepared by a maltose-based sol-gel route. Electrochim Acta 55:6761–6767

Li Y, Xiang K, Shi C, Zhou W, Zhu Y, Chen H (2017) Frogegg-like Li3V2(PO4)3/carbon composite with three dimensional porous structure and its improved electrochemical performance in lithium ion batteries. Mater Lett 204:104–107

Wang Y, Zhang X, He W, Wei C, Cheng Q, Li C (2016) In situ synthesis of biocarbon coated Li3V2(PO4)3 cathode material using lotus leaf as carbon source. J Mater Sci Mater Electron 27:12610–12617

Wang C, Li Z, Liu H, Wang Y (2017) Improved electrochemical performance of a Li3V2(PO4)3 cathode in a wide potential window for lithium-ion storage by surface N-doped carbon coating and bulk K-doping. New J Chem 41:8772–8780

Liu L, Lei X, Tang H, Zeng R, Chen Y, Zhang H (2015) Influences of La doping on magnetic and electrochemical properties of Li3V2(PO4)3/C cathode materials for lithium-ion batteries. Electrochim Acta 151:378–385

Yan J, Cao Y, Liu F (2016) Stable high-rate cycling electrode based on Li3V2(PO4)3/C using polyamide as a novel carbon source. RSC Adv 6:113228–113233

Li L, Fan C, Zhang X, Zeng T, Zhang W, Han S (2015) Synthesis of Li3V2(PO4)3/C for use as the cathode material in lithium ion batteries using polyvinylidene fluoride as the source of carbon. New J Chem 39:2627–2632

Qiao YQ, Tu JP, Wang XL, Gu CD (2012) The low and high temperature electrochemical performances of Li3V2(PO4)3/C cathode material for Li-ion batteries. J Power Sources 199:287–292

Qiao YQ, Wang XL, Xiang JY, Zhang D, Liu WL, Tu JP (2011) Electrochemical performance of Li3V2(PO4)3/C cathode materials using stearic acid as a carbon source. Electrochim Acta 56:2269–2275

Liang S, Hu J, Zhang Y, Wang Y, Cao X, Pan A (2016) Facile synthesis of sandwich-structured Li3V2(PO4)3/carbon composite as cathodes for high performance lithium-ion batteries. J Alloy Compd 683:178–185

Zhou X, Liu Y, Guo Y (2009) Effect of reduction agent on the performance of Li3V2(PO4)3/C positive material by one-step solid-state reaction. Electrochim Acta 54:2253–2258

Fan C, Han S, Zhang K, Li L, Zhang X (2014) Influences of the molecular structure of carbon sources on the structure, morphology and performances of Li3V2(PO4)3-C cathode for lithium ion batteries. New J Chem 38:4336–4343

Cheng Y, Zhou W, Feng K, Zhang H, Li X, Zhang H (2017) One-pot synthesis of 3D hierarchical porous Li3V2(PO4)3/C nanocomposites for high-rate and long-life lithium ion batteries. RSC Adv 7:38415–38423

Zhang J, Wang X, Zhang B, Tong H (2015) Porous spherical LiMnPO4·2Li3V2(PO4)3/C cathode material synthesized via spray-drying route using oxalate complex for lithium-ion batteries. Electrochim Acta 180:507–513

Wei Q, Xu Y, Li Q, Tan S, Ren W, An Q, Mai L (2016) Novel layered Li3V2(PO4)3/rGO&C sheets as high-rate and long-life lithium ion battery cathodes. Chem Commun 52:8730–8732

Chen H, Wang ZK, Li GD, Guo FF, Fan MH, Wu XY, Cao XC (2015) Enhanced electrochemical performance of Li3V2(PO4)3 microspheres assembled with nanoparticles embedded in a carbon matrix. RSC Adv 5:31410–31414

He W, Wei C, Zhang X, Wang Y, Liu Q, Shen J, Wang L, Yue Y (2016) Li3V2(PO4)3/LiFePO4 composite hollow microspheres for wide voltage lithium ion batteries. Electrochim Acta 219:682–692

Zhang X, Guo H, Li X, Wang Z, Wu L (2012) High tap-density Li3V2(PO4)3/C composite material synthesized by sol spray-drying and post-calcining method. Electrochim Acta 64:65–70

Wang X, Dong S, Wang H (2017) Three-dimensional CNTs wrapped Li3V2(PO4)3 microspheres cathode with high-rate capability and cycling stability for Li-ion batteries. Solid State Ion 309:146–151

Hu Y, Ma X, Guo P, Jaeger F, Wang Z (2017) 3D graphene-encapsulated Li3V2(PO4)3 microspheres as a high-performance cathode material for energy storage. J Alloy Compd 723:873–879

Jung DS, Ko YN, Kang YC, Park SB (2014) Recent progress in electrode materials produced by spray pyrolysis for next-generation lithium ion batteries. Adv Powder Technol 25:18–31

Fu P, Zhao Y, Dong Y, Hou X (2015) Synthesis of high tap density Li3V2(PO4)3 cathode materials using mixed lithium precursors. J Phys Chem Solids 71:394–399

Pan A, Liu J, Zhang J-G, Xu W, Cao G, Nie Z, Arey BW, Liang S (2010) Nano-structured Li3V2(PO4)3/carbon composite for high-rate lithium-ion batteries. Electrochem Commun 12:1674–1677

Yang X, Li C, Fu R (2016) Nitrogen-enriched carbon with extremely high mesoporosity and tunable mesopore size for high-performance supercapacitors. J Power Sources 319:66–72

Yang X, Huang H, Li Z, Zhong M, Zhang G, Wu D (2014) Preparation and lithium-storage performance of carbon/silica composite with a unique porous bicontinuous nanostructure. Carbon 77:275–280

Li C, Li Z, Ye X, Yang X, Zhang G, Li Z (2018) Crosslinking-induced spontaneous growth: A novel strategy for synthesizing sandwich-type graphene@Fe3O4 dots/amorphous carbon with high lithium storage performance. Chem Eng J 334:1614–1620

Yang X, Yu J, Lin Z, Fu R (2017) Investigation on the applicable pore size of nanoporous carbon for electrochemical double-layer formation at different current densities. Electrochim Acta 241:189–196

Liu Q, Yang F, Wang S, Feng L, Zhang W, Wei H (2013) A simple diethylene glycol-assisted synthesis and high rate performance of Li3V2(PO4)3/C composites as cathode material for Li-ion batteries. Electrochim Acta 111:903–908

Oh RG, Hong JE, Jung HW, Ryu KS (2015) Electrochemical properties of Li3-xNaxV2-xTix(PO4)3/C cathode materials in lithium ion batteries. J Power Sources 295:1–8

Acknowledgements

The authors thank the National Natural Science Foundation of China (No. 21401061), the Anhui Provincial Natural Science Foundation (No. 1308085QB41), the Key project of Anhui Universities support program for Outstanding Youth (No. gxyqZD2016111), and Anhui Provincial Innovation Team of Design and Application of Advanced Energetic Materials (KJ2015TD003).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Highlights

-

Beta-cyclodextrin serves as a novel chelating agent to form highly dispersed sol.

-

Li3V2(PO4)3/C porous microspheres are obtained by a sol spray-drying method.

-

The microspheres are made of nanoparticles ca. 30–50 nm in size.

-

The Li3V2(PO4)3/C presents high-rate capacity with good cyclability.

Rights and permissions

About this article

Cite this article

Liu, X., Feng, X., Xu, X. et al. Sol-assisted spray-drying synthesis of porous Li3V2(PO4)3/C microspheres as high-activity cathode materials for lithium-ion batteries. J Sol-Gel Sci Technol 86, 343–350 (2018). https://doi.org/10.1007/s10971-018-4644-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4644-8