Abstract

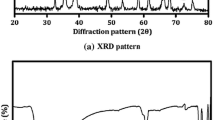

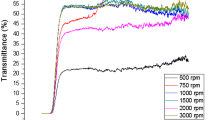

Gamma-ray irradiation assisted polyacrylamide gel route was used to prepare CoAl2O4 nanoblue pigments. In this route, citric acid was used as a carboxyl and hydroxyl type chelating agent. The phase purity, morphology, and optical and fluorescence properties of as-prepared samples were analyzed via X-ray diffraction (XRD), Fourier transform infrared (FTIR) spectrometer, transmission electron microscopy (TEM), UV–Visible spectrophotometer, and a confocal Raman system. XRD analysis indicates that the xerogel sintered at relatively low temperature (500 °C) to obtain single phase CoAl2O4 nanopowders. The primary crystal of CoAl2O4 nanoblue pigment is only 28 nm characterized by TEM, which is more likely to be realized with high uniformity than that the CoAl2O4 nanopowders prepared by conventional polyacrylamide gel route. Optical properties of CoAl2O4 nanoblue pigment shows that the optical energy gap (Eg) of nanoblue pigment increases with the decrease of crystallite size. The CIE parameter of CoAl2O4 nanoblue pigment indicates that a different sintering temperature causes a variation in the color of nanoparticles. The fluorescence spectra show that a major blue emission band around 400 nm and a weaker side band located at 430 nm are observed when the excitation wavelength is 325 nm. The chelation mechanism and fluorescence mechanism of the CoAl2O4 nanoblue pigment have been analyzed based on the experimental results.

A cubic nano-CoAl2O4 pigments were synthesized by γ-ray irradiation assisted polyacrylamide gel route. The nano-CoAl2O4 pigments with high uniformity than that the CoAl2O4 nanopowders prepared by conventional polyacrylamide gel route. The SAED pattern revealed that the CoAl2O4 nanoparticles possess interplanar spacing of 2.8651, 2.4434, 2.0258, 1.5586, 1.4327, 1.3657, and 1.1549 Å corresponding to the (220), (311), (400), (511), (440), (531), and (444) planes, respectively. The UV–Vis absorption spectrum shows three obvious absorption peaks at 551, 590, and 628 nm and the CIE parameter is consistent with the real photos.

Similar content being viewed by others

References

Jafari M, Hassanzadeh-Tabrizi SA, Ghashang M, Pournajaf R (2014) Ceram Int 40:11877–11881

Bulte JWM, Kraitchman DL (2004) NMR Biomed 17:484–499

Zayat M, Levy D (2000) Chem Mater 12:2763–2769

Son SJ, Reichel J, He B, Schuchman M, Lee SB (2005) J Am Chem Soc 127:7316–7317

Basak J, Hardia N, Saxena S, Dixit R, Dwivedi R, Bhadauria S, Prasad R (2007) Ind Eng Chem Res 46:7039–7044

de Herval LKS, Tuncer Arslanlar Y, Ayvacikli M, Iikawa F, Nobrega JA, Pizani PS, Galvão Gobato Y, Can N, Henini M, de Godoy MPF (2015) J Lumin 163:17–20

Yoon S, Bierwagen J, Trottmann M, Walfort B, Gartmann N, Weidenkaff A, Hagemann H, Pokrant S (2015) J Lumin 167:126–131

Ji L, Tang S, Zeng HC, Lin J, Tan KL (2001) Appl Catal A 207:247–255

Melo DMA, Cunha JD, Fernandes GDG, Bernardi MI, Melo MAF, Martinelli AE (2003) Mater Res Bull 38:1559–1564

Li W, Li J, Guo J (2003) J Eur Ceram Soc 23:2289–2295

Otero Area´n CO, Mentruit MP, Platero EE, Xamena FXL, Parra JB (1999) Mater Lett 39:22–27

Merikhi J, Jungk HO, Feldmann CJ (2000) J Mater Chem 10:1311–1314

Stangar UL, Orel B, Krajnc M (2003) J Sol Gel Sci Technol 26:771–775

Manikandan A, Durka M, Amutha Selvi M, Arul Antony S (2016) J Nanosci Nanotechno 16:448–456

Gama L, Ribeiro MA, Barros BS, Kiminami RHA, Weber IT, Costa ACFM (2009) J Alloy Comp 483:453–455

Gholami T, Salavati-Niasari M, Varshoy S (2016) J Hydrog Energ 41:9418–9426

Ahmed IS (2011) Mater Res Bull 46:2548–2553

Torkian L, Daghighi M (2014) Adv Powder Technol 25:739–744

Chandradass J, Balasubramanian M, Kim KH (2010) J Alloy Comp 506:395–399

Duan XL, Pan M, Yu FP, Yuan DR (2011) J Alloy Comp 509:1079–1083

Kurajica S, Popovic J, Tkalcec E, Grzeta B, Mandic V (2012) Mater Chem Phys 135:587–593

Xi XL, Nie ZR, Ma LW, Li L, Xu XY, Zuo TY (2012) Powder Technol 226:114–116

Aly KA, Khalil NM, Algamal Y, Saleem QMA (2016) J Alloy Comp 676:606–612

Peymannia M, Soleimani-Gorgani A, Ghahari M, Jalili M (2015) Ceram Int 41:9115–9121

Peymannia M, Soleimani-Gorgani A, Ghahari M, Najafi F (2014) J Eur Ceram Soc 34:3119–3126

Wang QK, Chang QB, Wang YQ, Wang X, Zhou JE (2016) Mater Lett 173:64–67

Chen ZZ, Shi EW, Li WJ, Zheng YQ, Zhong WZ (2002) Mater Lett 55:281–284

Jafari M, Hassanzadeh-Tabrizi SA (2014) Powder Technol 266:236–239

Zhao X, Yang H, Cui Z, Li R, Feng W (2017) Mater Technol 32:870–880

Saket-Oskoui M, Khatamian M, Nofouzi K, Yavari A (2014) Adv Powder Technol 25:1634–1642

Di LJ, Yang H, Xian T, Chen XJ (2017) Materials 10:1118

Zheng CX, Yang H, Cui ZM, Zhang HM, Wang XX (2017) Nanoscale Res Lett 12:608

Wang SF, Lv HB, Zhou XS, Fu YQ, Zu XT (2014) Nanosci Nanotech Lett 6:758–771

Sin A, Odier P (2000) Adv Mater 12:649–652

Wang SF, Li DM, Yang CQ, Sun GA, Zhang J, Xia YH, Xie CM, Yang GX, Zhou M, Liu W (2017) J Sol Gel Sci Technol 84:169–179

Wang F, Yang H, Zhang YC (2018) Mat Sci Semicon Proc 73:58–66

Gabrovska M, Crisan D, Stanica N, Nikolova D, Bilyarska L, Crisan M, Edreva-Kardjieva R (2014) Rev Roum Chim 59:445–450

Renouprez AJ (1992) Acta Phys Pol Α 82:295–308

Ianos R, Borcǎnescu S, Lazaǎu R (2014) Chem Eng J 240:260–263

Salavati-Niasari M, Farhadi-Khouzani M, Davar F (2009) J Sol Gel Sci Technol 52:321–327

Mindru I, Marinescu G, Gingasu D, Patron L, Ghica C, Giurginca M (2010) Mater Chem Phys 122:491–497

Ahmed IS, Dessouki HA, Ali AA (2008) Spectrochim Acta A 71:616–620

de Souza LKC, Zamian JR, daRocha Filho GN, Soledade LEB, dos Santos IMG, Souza AG, Scheller T, Angelica RS, da Costa CEF (2009) Dyes Pigments 81:187–192

El Habra N, Crociani L, Sada C, Zanella P, Casarin M, Rossetto G, Carta G, Paolucci G (2007) Chem Mater 19:3381–3386

Rangappa D, Naka T, Kondo A, Ishii M, Kobayashi T, Adschiri T (2007) J Am Chem Soc 129:11061–11066

Agilandeswari K, Ruban Kumar A (2015) AIP Conf Proc 1665:120022-1–120022-3. https://doi.org/10.1063/1.4918129

Ahmad F (2014) J Alloy Comp 586:605–610

Zheng WC, Wu XX, Fang W, Mei Y (2007) Spectrochim Acta A 66:1295–1299

Ho C, Yu JC, Kwong T, Mak AC, Lai S (2005) Chem Mater 17:4514–4522

Jayasree S, Manikandan A, Mohideen AM, Barathiraja C, Antony SA (2015) Adv Sci Eng Med 7:672–682

Pelagotti A, Pezzati L, Bevilacqua N, Vascotto V, Reillon V, Daffara C (2005) A study of UV fluorescence emission of painting materials. ‘05–8th International Conference on Non-Destructive Investigations and Microanalysis for the Diagnostics and Conservation of the Cultural and Environmental Heritage. Lecce, CD-ROM, A97, 2005

Alves E, Marques C, da Silva RC, Monteiro T, Soares J, McHargue C, Ononye LC, Allard LF (2003) Nucl Instrum Meth B 207:55–62

Monteiro T, Soares MJ, Santos L, Boemare C, Cascalheira J, Alves LC, Alves E (2002) Radiat Eff Defect S 157:1117–1122

Kuleshov NNV, Mikhailov VP, Scherbitsky VG, Prokoshin PV, Yumashev KV (1993) J Lumin 55:265–269

Ahn KS, Yan YF, Kang MS, Kim JY, Shet S, Wang HL, Turner J, Al-Jassim M (2009) Appl Phys Lett 95:022116

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51662027, and 61540043).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Highlights

-

CoAl2O4 nanoblue pigments were prepared by γ-ray irradiation assisted polyacrylamide gel route.

-

CoAl2O4 nanoblue pigments with high uniformity.

-

Sintering temperature causes a variation in the color and Eg value of CoAl2O4 nanoparticles.

-

The chelation and fluorescence mechanisms of the CoAl2O4 nanoblue pigment have been analyzed.

Rights and permissions

About this article

Cite this article

Gao, H., Yang, H., Wang, S. et al. A new route for the preparation of CoAl2O4 nanoblue pigments with high uniformity and its optical properties. J Sol-Gel Sci Technol 86, 206–216 (2018). https://doi.org/10.1007/s10971-018-4609-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4609-y