Abstract

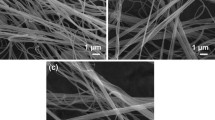

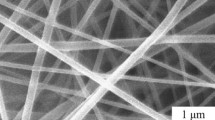

Fast and large-scale production of mesoporous titania nanofibers was achieved by solution blow spinning. The blow spinning setup provides a method to prepare titania nanofibers in a safe and scalable way without using a high-voltage electric field. Titania microstructure and porosity can be modified by adding a suitable template, such as pluronic polymers. The blow spun titania nanofibers had a good performance on the photocatalytic degradation of tetracycline and could be easily removed from the tetracycline aqueous solution due to their large aspect ratio. Solution blow spinning method has a great potential for the large-scale production of titania nanofibers with good photocatalytic properties.

Graphical Abstract

Similar content being viewed by others

References

Zhang W, Zhu R, Ke L, Liu X, Liu B, Ramakrishna S (2010) Small 6:2176–2182

Chuangchote S, Jitputti J, Sagawa T, Yoshikawa S (2009) ACS Appl Mater Interfaces 1:1140–1143

Zheng Z, Liu H, Ye J, Zhao J, Waclawik ER, Zhu H (2010) J Mol Catal A-Chem 316:75–82

Li D, McCann JT, Gratt M, Xia YN (2004) Chem Phys Lett 394:387–391

Caruso RA, Schattka JH, Greiner A (2001) Adv Mater 13:1577–1579

Kim S-W, Han TH, Kim J, Gwon H, Moon H-S, Kang S-W, Kim SO, Kang K (2009) Acs Nano 3:1085–1090

Li D, Xia YN (2003) Nano Lett 3:555–560

Li D, Xia YN (2004) Nano Lett 4:933–938

Yang G, Chang W, Yan W (2014) J Sol-Gel Sci Technol 69:473–479

Qin D, Liang G, Gu A, Yuan L (2013) J Sol-Gel Sci Technol 67:451–457

Luo CJ, Stoyanov SD, Stride E, Pelan E, Edirisinghe M (2012) Chem Soc Rev 41:4708–4735

Vasquez H, Gutierrez H, Lozano K, Leal G (2015) J Eng Fiber Fabr 10:129–136

Bao N, Wei Z, Ma Z, Liu F, Yin GJ (2010) J Hazar Mater 174:129–136

Liu H, Zhou X, Chen Y, Li T, Pei S (2014) J Sol-Gel Sci Technol 71:102–108

Medeiros ES, Glenn GM, Klamczynski AP, Orts WJ, Mattoso LHC (2009) J Appl Polym Sci 113:2322–2330

Cheng B, Tao X, Shi L, Yan G, Zhuang X (2014) Ceram Int 40:15013–15018

Li L, Kang W, Zhuang X, Shi J, Zhao Y, Cheng B (2015) Mater Lett 160:533–536

Chattopadhyay S, Saha J, De G (2014) J Mater Chem A 2:19029–19035

Abdal-hay A, Hamdy AS, Lim JH (2014) Ceram Int 40:15403–15409

Lisboa Costa D, Santos Leite R, Araujo Neves G, Navarro de Lima Santana L, Souto Medeiros E, Rodrigues Menezes R (2016) Mat Lett 183:109–113

Abdal-hay A, Hamdy MAS, Khalil KA (2015) ACS Appl Mater Interfaces 7:13329–13341

Costa RGF, Brichi GS, Ribeiro C, Mattoso LHC (2016) Polym Bull. doi:10.1007/s00289-016-1635-1

Li H, Zhang W, Pan W (2011) J Am Ceram Soc 94:3184–3187

Kartini I, Meredith P, Da Costa JCD, Lu GQ (2004) J Sol-Gel Sci Technol 31:185–189

Lopez R, Gomez R (2012) J Sol-Gel Sci Technol 61:1–7

Zhang QH, Gao L, Guo JK (2000) Appl Catal B-Environ 26:207–215

Jang HD, Kim SK, Kim SJ (2001) J Nanopart Res 3:141–147

Acknowledgments

The authors wish to thank CONACYT-Mexico for its support through CB-239354 project and Mario Hernandez for his 3D model of the spinneret. R. Cruz-Silva thanks the support of the Center of Innovation Program from Japan Science and Technology Agency, JST.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Gonzalez-Abrego, M., Hernandez-Granados, A., Guerrero-Bermea, C. et al. Mesoporous titania nanofibers by solution blow spinning. J Sol-Gel Sci Technol 81, 468–474 (2017). https://doi.org/10.1007/s10971-016-4210-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-016-4210-1