Abstract

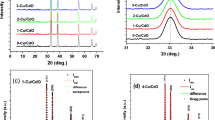

The Cd10−x Cu x ZnO films were prepared for various x = 0.25, 0.50, 0.75 and 1.0 by sol–gel method. The structural and surface morphology of the films was investigated by XRD and atomic force microscopy. The results indicate that the crystallinity of the films is improved with Cu doping. The maximum crystallite size was 23 nm and minimum dislocation density 1.890 × 1013 lines/m2. The study of optical properties revealed that optical band gap firstly decreases with doping and then increase with further increase in doping. The obtained results indicate that the structural and optical properties of Cd10−x Cu x ZnO composite films are controlled with Cd/Cu ratio.

Graphical Abstract

Similar content being viewed by others

References

Wang ZL, Kong XY, Ding Y, Gao P, Hughes WL, Yang R, Zhang Y (2004) Adv Funct Mater 14(10):943

Li YZ, Li XM, Gaoa XD (2011) J Alloys Compd 509(26):7193

Phan DT, Chung GS (2011) Appl Surf Sci 257(9):4339

Hembram K, Sivaprahasam D, Rao TN (2011) J Eur Ceram Soc 31(10):1905

Liu K, Sakurai M, Aono M (2011) Sensors Actuators B Chem 157(1):98

Lee CT, Chiu YS, Ho SC, Lee YJ (2011) Sensors 11(5):4648

Xu CX, Sun XW (2003) Appl Phys Lett 83(18):3806

Kim JH, Hong YC, Uhm HS (2007) Chem Phys Lett 443:122

Wang WW, Zhu YJ (2004) Inorg Chem Commun 7:1003

Mahmoud WE, Al-Ghamdi AA (2010) Opt Laser Technol 42:1134–1138

Freeman AJ, Poeppelmeier KR, Mason TO, Chang RPH, Marks TJ (2000) Mater Res Soc Bull 25:45

Yan M, Lane M, Kannewurf CR, Chang RPH (2001) Appl Phys Lett 78:2342

Ghosh PK, Maity R, Chattopadhyay KK (2004) Sol Energy Mater Sol Cells 81:279

Gupta RK, Yakuphanoglu F, Amanullah FM (2011) Phys E 43:1666

Yahia IS, Salem GF, Yakuphanoglu F (2013) Superlattices Microstruct 64:178–184

Chung SM, Shin JH, Lee JM, Ryu MK, Cheong WS, Park SH, Hwang CS, Cho KI (2011) J Nanosci Nanotechnol 11(1):782–786

Gong H, Hu JQ, Wang JH, Ong CH, Zhu FR (2006) Sensors Actuators B Chem 115(1):247–251

Sung NE, Kang SW, Shin HJ, Lee HK, Lee IJ (2013) Thin Solid Films 547:285–288

Mani GK, Rayappan JBB (2014) J Alloys Compd 582:414–419

Wang DY, Zhou J, Liu GZ (2009) J Alloys Compd 487:545–549

Koao LF, Dejene BF, Swart HC (2014) Phys B 439:173–176

Xia CH, Wang F, Hu CL (2014) J Alloys Compd 589:604–608

Lin HT, Chin TS, Shih JC, Lin SH, Hong TM (2004) Appl Phys Lett 85:621

Gupta RK, Serbetçi Z, Yakuphanoglu F (2012) J Alloys Compd 515:96–100

JCPDS—International Centre for Diffraction Data, Card No. 05-0640 (1997)

Barret CS, Massalski TB (1980) Structure of metals. Pergamon Press, Oxford

Dakhel AA (2014) Solid State Sci 31:1–7

Elttayef Abdul-Hussein K, Ajeel Hayder M, Khudiar Ausama I (2013) J Mater Res Technol 2:182–187

Yakuphanoglu F (2012) Sensors Actuators A 173:141–144

Alahmed ZA, Yakuphanoglu F (2013) Microelectron Eng 110:25–28

Green M, Hussain Z (1991) J Appl Phys 69:7788

Satoh N, Nakashima T, Kamikura K, Yamamoto K (2008) Nat Nanotechnol 3:106

Dakhel AA (2012) J Alloys Compd 539:26–31

Acknowledgments

This paper was funded by the Deanship of Scientific Research (DSR), King Abdulaziz University, Jeddah, under Grant No. (619-130-D1435). The authors, therefore, acknowledge with thanks DSR technical and financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al Orainy, R.H. Optical properties of nanostructured Cd10−x Cu x ZnO composite films by sol–gel method. J Sol-Gel Sci Technol 77, 371–377 (2016). https://doi.org/10.1007/s10971-015-3863-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3863-5