Abstract

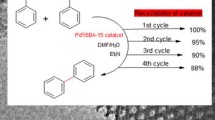

Here we describe a new platinum catalyst comprised of Pt(0) nanoparticles immobilized on a modified magnetic mesoporous silica support modified with electron donor groups (–N). The material is constituted of controlled pore size (2.4–4.1 nm) and serves as a template for the generation of Pt nanoparticles (2–4 nm). The catalytic activity of the supported Pt nanoparticles was investigated in the catalytic reduction of anthracene under ultra-mild conditions. A complete morphological characterization of the hybrid organic–inorganic composite which confirms the formation of the hybrid material is also given. The catalyst was easily recycled using a small magnet, and it could be reused at least twice without significant loss of its catalytic activity. ICP–OES reveals that after the recyclability study no leaching of Pt or Si could be detected in the products (<0.01 ppm) which confirms the chemical stability of the material allowing it to be used as a potential hydrogenation catalyst for solid–liquid reactions with facile catalyst recovery.

Graphical Abstract

Similar content being viewed by others

References

Atabaev TJ, Lee JH, Han DW, Hwang H, Hong NH (2013) Nanotechnology 24:345603–345610

Yin Y, Rioux RM, Erdonmez CK, Hughes S, Somorjai GA, Alivisatos AP (2004) Science 304:711–714

Jeong GH, Kim EG, Kim SB, Park ED, Kim SW (2011) Micropor Mesopor Mat 144:134–139

Carniato F, Bisio C, Paul G, Gatti G, Bertinetti L, Coluccia S, Marchese L (2010) J Mater Chem 20:5504–5509

Joo SH, Park JY, Tsung CK, Yamada Y, Yang P, Somorjai GA (2009) Nat Mater 8:126–131

Xie R, Wang H, Gao P, Xia L, Zhang Z, Zhao T, Sun Y (2015) Appl Catal A Gen 492:93–99

Malay O, Yilgor I, Menceloglu YZ (2013) J Sol–Gel Sci Technol 67:351–361

Jacinto MJ, Kiyohara PK, Masunaga SH, Jardim RF, Rossi LM (2008) Appl Catal A Gen 338:52–57

Fang Y, Chen Y, Li X, Zhou X, Li J, Tang W, Huang J, Jin J, Ma J (2014) J Mol Catal A Chem 392:16–21

Jacinto MJ, Santos OHCF, Landers R, Kiyohara PK, Rossi LM (2009) Appl Catal B Env 90:688–692

Murugan E, Jebaranjitham N (2015) Chem Eng J 259:266–276

Darwish MSA, Kunz U, Peuker UJ (2012) Appl Polym Sci 129:1806–1811

Qureshi ZS, Sarawade PB, Albert M, D’Elia V, Hedhili MN, Köhler K (2015) Chem Cat Chem 7:635–642

Foppa L, Dupont J, Scheeren C (2014) RSC 4:16583–16588

Lee DH, Jung JY, Jin MJ (2010) RSC 12:2024–2029

Ray S, Bhaumik A, Pramanik M, Mukhopadhyay C (2014) RSC 4:15441–15450

Carlier E, Guyot A, Revillon A (1992) Reac Polym 18:167–171

Rosenholm JM, Lindén M (2007) Chem Mater 19:5023–5034

Ortiz HIM, Mercado YP, Silva JAM, Maldonado YO, Castruita G, Cerda LAG (2013) Ceram Int 40:9701–9707

Tan SY, Ang CY, Li P, Yap QM, Zhao Y (2014) Chem Eur J 20:11276–11282

Niu D, Liu Z, Li Y, Luo X, Zhang J, Gong J, Shi J (2014) Adv Mater 26:4947–4953

Yang P, Gai S, Lin J (2012) Chem Soc Rev 41:3679–3698

Nador F, Moglie Y, Vitale C, Yus M, Alonso F, Radivoy G (2010) Tetrahedron 66:4318–4325

Liao W, Liu HW, Chen HJ, Chang WY, Chiu KH, Wai CM (2011) Chemosphere 82:573–580

Yuan T, Marshall WD (2005) J Hazard Mater B 126:149–157

Nelkenbaum E, Dror I, Berkowitz B (2007) Chemosphere 68:210–217

Li G, Liu Y, Du H (2015) Org Biomol Chem 13:2875–2878

Park J, An K, Hwang Y, Park JG, Noh HJ, Kim JY, Park JH, Hwang NM, Hyeon T (2004) Nat Mater 3:891

Kresge CT, Leonowics ME, Roth WJ, Vartuli JC, Beck JS (1992) Nature 359:710

Briggs D, Seah MP (1990) Practical surface analysis, vol 1 Auger and X-ray photoelectron spectroscopy. Willey, New York

Smith GC (1994) Surface analysis by electron spectroscopy. Plenum, New York

Scofield JH (1996) J Electron Spectrosc 8:129–132

Moulder JF, Stickle WF, Sobol PE, Bomben KD (1992) in: J. Chastian, Handbook of X-ray photoelectron spectroscopy, Perkin-Elmer Corp., Minnesota

Naumkin AV, Kraut-Vass A, Gaarenstroom SW, Powell CJ (2012)NIST X-ray photoelectron spectroscopy database, 20, V. 4.1. Retrieved from: http://srdata.nist.gov/xps/Version_his.aspx, last accessed: 04/03/2015 at 14:52

Acknowledgments

The authors are grateful to Fundação de Amparo a Pesquisa do Estado do Mato Grosso (FAPEMAT) and Conselho Nacional de Desenvolvimento Científico e Tecnológico(CNPq) for financial support, and indebted to LEFE (Brazil), LME-DEMA (Brazil) and LMC-UnB for the XPS, TEM and BET analyses, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jacinto, M.J., Wizbiki, M., Justino, L.C. et al. Platinum-supported mesoporous silica of facile recovery as a catalyst for hydrogenation of polyaromatic hydrocarbons under ultra-mild conditions. J Sol-Gel Sci Technol 77, 298–305 (2016). https://doi.org/10.1007/s10971-015-3854-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-015-3854-6