Abstract

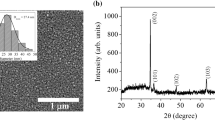

Indium–zinc oxide (IZO) thin films were fabricated by spin coating using acetate- and nitrate-based precursors, and thin film transistors (TFTs) were further fabricated employing the IZO films as the active channel layer. The impact of the indium concentration on the properties of the solutions, the structure and optical transmittance properties of the IZO films and the IZO TFTs device properties were researched in this article. The IZO films with amorphous structure were obtained when the annealing temperature is 500 °C. The transmittance could reach ~90 % (including glass substrate) during the visible region of 400–760 nm. Higher indium concentration can improve the IZO TFTs’ filed effect mobility. A Ion–Ioff of 6.0 × 106 and a mobility of 0.13 cm2/Vs were obtained when the indium concentration is 60 %. IZO TFTs’ performance could deteriorate when the indium concentration more than 60 %.

Similar content being viewed by others

References

Nomura K, Ohta H, Takagi A, Kamiya T, Hirano M, Honoso H (2004) Nature 432:488–492

Hosono H (2006) J Non Cryst Solids 352:851–858

Kamiya T, Nomura K, Hosono H (2010) Sci Technol Adv Mater 11:044305

Choi CG, Seo SJ, Bae BS (2008) Electrochem Solid State Lett 11(1):H7

Jeong S, Ha YG, Moon J, Facchetti A, Marks TJ (2010) Adv Mater 22:1346–1350

Seo SJ, Choi CG, Hwang YH, Bae BS (2009) J Phys D Appl Phys 42:035106

Chen KJ, Hung FY, Chang SJ, Young SJ, Hu ZS, Chang SP (2010) J Sol–Gel Sci Technol 54:347–354

Wang Y, Liu XW, Sun XW, Zhao JL, Goh GKL, Vu QV, Yu HY (2010) J Sol–Gel Sci Technol 55:322–327

Kim YH, Han MK, Han JI, Park SK (2010) Trans Electron Device 57(5):1009

Martins R, Barquinha P, Pimentel A, Pereira L, Fortunato E (2005) Phys Status Solid (A) 202(9):R95

Kim GH, Shin HS, Ahn BD, Kim KH, Park WJ, Kim HJ (2009) J Electrochem Soc 156(1):H7–H9

Kim SJ, Kim DL, Rim YS, Jeong WH, Kim DN, Yoon DH, Kim HJ (2011) J Cryst Growth 326:163–165

Pasquarelli RM, Curtis CJ, Miedaner A, Hest MFAMV, O’Hayre RP, Ginley DS (2010) Inorg Chem 49:5424–5431

Mottern ML, Tyholdt F, Ulyashin A, Helvoort ATJ, Verweij H, Bredesen R (2007) Thin Solid Films 515:3918–3926

Song K, Kim D, Li XS, Jun T, Jeong Y, Moon J (2009) J Mater Chem 19:8881–8886

Seo SJ, Choi CG, Hwang YH, Bae BS (2008) SID 08 DIGEST 1254

Lee DH, Chang YJ, Herman GS, Chang CH (2007) Adv Mater 19:843–847

Kim D, Koo CY, Song K, Jeong Y, Moon J (2009) Appl Phys Lett 95:103501

Banger KK, Yamashita Y, Mori K, Peterson RL, Leedham T, Rickard J, Sirringhaus H (2011) Nat Mater 10:45

Pasquarelli RM, Ginley DS, O’Hayre R (2011) Chem Soc Rev 40:5406–5441

Acknowledgments

This work was supported by National Natural Science Foundation of China under Grant No. 61006005 and Shanghai science and technology commission under Grant No. 10dz1100102.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, X., Li, Q., Xin, E. et al. Sol–gel processed indium zinc oxide thin film and transparent thin-film transistors. J Sol-Gel Sci Technol 65, 130–134 (2013). https://doi.org/10.1007/s10971-012-2916-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-012-2916-2