Abstract

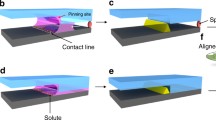

Patterning of sol gel based silica and silica–titania films has been developed at room temperature by soft lithographic technique. Corresponding metal alkoxides have been utilized for the preparation of precursor sols. Elastomeric stamps of polydimethylsiloxane (PDMS) are used to emboss patterns of a master grating on the as-prepared silica and silica–titania films obtained by sol gel process. Pressure-less capillary force lithography has been used to fabricate both 1-D and 2-D ordered structures of simple stripe patterns. A modified solvent assisted lithography and micro-molding in capillaries yielded stable and high fidelity 1-D structures for silica and silica–titania films over a large area.

Similar content being viewed by others

References:

Barrett CR (1993) Mater Res Soc Bull XVIII(7):3

Bryzek J (1996) Sensors July:4

Clark RA, Hieptas PB, Ewing AG (1997) Anal Chem 69:259

Wu MC, Lin LY, Lee SS, King CR (1996) Laser Focus World February:64

Briceno G, Chang HY, Sun XD, Schultz PG, Xiang XD (1995) Science 270:273

Bryzek J, Peterson K, McCulley W (1994) IEEE Spectrum May:20

Manz A (1996) CHIMIA 59:140

Kovacs GTA, Petersen K, Albin M (1996) Anal Chem 68:407A–4012A

Szendro I (2001) Proc SPIE 4284:80

Suh KY, Kim YS, Lee HH (2001) Adv Mater 13:1386

Xia Y, Rogers JA, Paul KE, Whitesides GM (1999) Chem Rev 99:1823

Xia Y, Whitesides GM (1998) Angew Chem Int Ed 37:550

Chou SY, Krauss PR, Renstrom PJ (1996) Science 272:85

Xia Y, Whitesides GM (1995) J Am Chem Soc 117:3274

Rogers JA, Meier M, Dodabalapur A (1998) Appl Phys Lett 73:1766

Schaffer E, Thurn-Albrecht T, Russell TP, Steiner U (2000) Nature 403:874

Piner RD, Zhu J, Xu F, Hong S, Mirkin CA (1999) Science 283:661

Drury CJ, Mutsaers CMJ, Hart CM, Matters M, de Leeuw DM (1998) Appl Phys Lett 73:108

Wang HY, Deeman N, Gauzner G, US Patent No. 7033683

Mukherjee R, Sharma A, Gonuguntla M, Patil GK (2008) J Nanosci Nanotech 8:1

Suh KY, Lee HH (2002) Adv Mater 14:346

Mukherjee R, Sharma A, Patil G, Faruqui D, Pattader PSG (2008) Bull Mater Sci 31:249

Xia Y, Kim E, Whitesides GM (1996) Chem Mater 8:1558

Fardad A, Andrews M, Milova G, Malek-Tabrizi A, Najafi I (1998) Appl Opt 37:2429

Herzig HP (1997) Micro-optics: elements, systems and applications. Taylor & Francis, London

Biswas PK, Kundu D, Ganguli D (1989) J Mater Sci Lett 8:1436

Atta AK, Biswas PK, Ganguli D (1990) J Non-Cryst Solids 125:202

Kim E, Xia Y, Whitesides GM (1995) Nature 376:581

Gonuguntla M, Sharma A, Mukherjee R, Subramaniam SA (2006) Langmuir 22:7066

Yu X, Wang Z, Xing R, Luan S, Han Y (2005) Polymer 46:11099

Erhardt MK, Nuzzo RG (1999) Langmuir 15:2188

Doshi DA, Huesing NK, Lu M, Fan H, Lu Y, Simmons-Potter K, Potter BG Jr, Hurd AJ, Brinker CJ (2000) Science 290:107

Jana S, Lim MA, Baek IC, Kim CH, Seok SI (2008) Mater Chem Phys 112:1008

Akram D, Ahmad S, Sharmin E, Ahmad S (2010) Macromol Chem Phys 211:412

Schrijnemakers K, Vansant EF (2001) Porous Mater J 8:83

Cheng P, Zheng M, Jin Y, Huang Q, Gu M (2003) Lett Matter 57:2989

Acknowledgments

The authors would like to thank the Director, CGCRI, Kolkata for support and encouragement for the work. This work has been carried out under the sponsorship of DST, Govt. of India (Sanction No.: DST/TSG/PT/2006/74). Two authors (DS and RDR) thankfully acknowledge DST for providing their research fellowships.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Sil, D., Deb Roy, R., Jana, S. et al. Patterning of sol gel thin films by capillary force assisted soft lithographic technique. J Sol-Gel Sci Technol 59, 117–127 (2011). https://doi.org/10.1007/s10971-011-2469-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-011-2469-9