Abstract

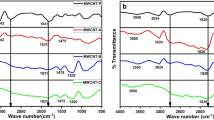

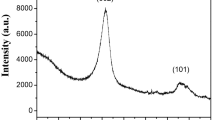

Carbon nanotubes (CNTs) were used to modify magnesium fluoride (MgF2) film via the spin coating technique. Nanoparticles of MgF2 were in situ synthesized on surfaces of CNTs resulted in the composites (MgF2–CNTs) by means of sol–gel technique. The sizes of the MgF2 nanoparticles in situ synthesized on CNTs surfaces could be modulated by processing the MgF2 sol–gel in different ways. The MgF2–CNTs as prepared was mixed with MgF2 sol to fabricate composite films (MgF2–CNTs/MgF2). Instead of adding directly CNTs, adding MgF2–CNTs, into MgF2 sol could effectively improve the dispersion of CNTs, avoid emergence of carbon clusters in the compsite film, decrease surface roughness of the film, and enhance the interaction between the CNTs and MgF2 matrix. In the paper, the MgF2 nanoparticles were in situ synthesized on the surfaces of multi-walled carbon nanotubes (MWCNTs) and single-walled carbon nanotubes (SWCNTs) respectively to prepare MgF2–SWCNTs/MgF2 and MgF2–MWCNTs/MgF2 composite films. Experimental results showed that the transparency of the MgF2–SWCNTs/MgF2 composite film was higher than that of the MgF2–MWCNTs/MgF2 film in the range of ultraviolet, visible and near-infrared wavelengths. The results showed SWCNTS could be an ideal reinforcement of MgF2 films to get good toughness, and retain its optical transmittance at the same time.

Similar content being viewed by others

References

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Qian D, Wagner GJ, Liu WK et al (2002) Mechanics of carbon nanotubes. Appl Mech Rev 55:495–533

Hone J, Llaguno MC, Biercuk MJ et al (2002) Thermal properties of carbon nanotubes and nanotube-based materials. Appl Phys A: Mater Sci Process 74:339–343

Gao L, Zhou XF, Ding YL (2007) Effective thermal and electrical conductivity of carbon nanotube composites. Chem Phys Lett 434:297–300

Zhou TL, Wang X, Liu XH et al (2010) Improved thermal conductivity of epoxy composites using a hybrid multi-walled carbon nanotube/micro-SiC filler. Carbon 48:1171–1176

Pasupuleti S, Peddetti R, Santhanam S, Jen KP, Wing ZN, Hecht M, Halloran JP (2008) Toughening behavior in a carbon nanotube reinforced silicon nitride composite. Mater Sci Eng A 491:224–229

Noguchi T, Magario A, Fukazawa S et al (2004) Carbon nanotube/aluminium composites with uniform dispersion. Mater Trans 45(2):602–604

Laha T, Agarwat A, Tim M et al (2004) Synthesis and characterization of plasma spray formed carbon nanotube reinforced aluminum composite. Mater Sci Eng A 381:249–258

Wang J, Kou H, Liu X et al (2007) Reinforcement of mullite matrix with multi-walled carbon nanotubes. Ceram Int 33(5):719–722

Balani K, Zhang T, Karakoti A, Li WZ et al (2008) In situ carbon nanotube reinforcements in a plasma-sprayed aluminum oxide nanocomposite coating. Acta Mater 56(3):571–579

Estili M, Kawasaki A (2008) An approach to mass-producing individually alumina-decorated multi-walled carbon nanotubes with optimized and controlled compositions. Scripta Mater 58:906–909

Morisada Y, Miyamoto Y, Takaura Y et al (2007) Mechanical properties of SiC composites incorporating SiC-coated multi-walled carbon nanotubes. Int J Refract Metal Hard Mater 4(25):322–327

Yan S, Lian G, Xue GY, Xia L et al (2009) Preparation and electrical characterization of carbon nanotube/ZrO2 composite ceramics. J Phys: Conf Ser 152:1–6

Zhan GD, Kuntz JD, Wan J et al (2003) Single-Wall Carbon Nanotubes as Attractive Toughening Agents in Alumina-Based Nanocomposites. Nat Mater 2(1):38–42

Dusza J, Blugan G, Morgiel J et al (2009) Hot-pressed and spark plasma sintered zirconia/carbon nanofiber composites. J Eur Ceram Soc 29(15):3177–3184

Inam F, Yan H, Peijs T et al (2010) Electrically conductive alumina–carbon nanocomposites prepared by spark plasma sintering. J Eur Ceram Soc 30(2):153–157

Jiang L, Gao L (2008) Densified multiwalled carbon nanotubes–titanium nitride composites with enhanced thermal properties. Ceram Int 34(1):231–235

Show Y, Takahashi K (2009) Stainless steel bipolar plate coated with carbon nanotube (CNT)/polytetrafluoroethylene (PTFE) composite film for proton exchange membrane fuel cell (PEMFC). J Power Sour 190:322–325

Shin DH, Yoon KH, Kwon OH et al (2006) Surface Resistivity and Rheological Behaviors of Carboxylated Multiwall Carbon Nanotube-Filled PET Composite Film. J Appl Polym Sci 99:900–904

Wang Z, Zhu ZZ, Shi J et al (2007) Electrocatalytic oxidation of formaldehyde on platinum well-dispersed into single-wall carbon nanotube/polyaniline composite film. Appl Surf Sci 253:8811–8817

Umasankar Y, Shie JW, Chen SM (2009) Electrocatalytic activity of oxygen and hydrogen peroxide reduction at poly (iron tetra(o-aminophenyl) porphyrin) coated multiwalled carbon nanotube composite film. J Electrochem Soc 156(12):238–244

Lee J, Park EJ, Choi J et al (2010) Polyurethane/PEG-modified MWCNT composite film for the chemical vapor sensor application. Synth Met 160:566–574

Sun ZQ, Cai Q, Song XP (2008) Microstructure and electrical conductivity of Au-MgF2 nanoparticle cermet films. Thin Solid Films 516:2280–2285

He YP, Zhang ZY, Hoffmann C et al (2008) Embedding Ag nanoparticles into MgF2 nanorod Arrays. Adv Funct Mater 18(11):1676–1684

Sun ZQ, Xiao L, Cao L et al (2009) Optical nonlinear characteristics of MgF2 films containing Cu nanoparticles. Chin Opt Lett 10(7):964–966

Wojciechowska M, Zielinski M, Pietrowski M (2003) MgF2 as a non-conventional catalyst support. J Fluor Chem 1(120):1–11

Kalevaru VN, Raju BD, Rao VV et al (2009) Preparation, characterization and catalytic evaluation of MgF2 supported V2O5 catalysts for ammoxidation of 3-picoline. Appl Catal A: Gen 352:223–233

Hannes K, Erhard K, Andreas H et al (2008) Transparent MgF2-films by sol-gel coating: synthesis and optical properties. Thin Solid Films 516:4175–4177

Tsuyoshi M, Hitoshi I, Akira T (2008) Investigation of MgF2 optical thin films with ultralow refractive indices prepared from autoclaved sols. Appl Opt 13(47):246–250

Tsuyoshi M, Hitoshi I, Izumi M et al (2004) Investigations of MgF2 optical thin films prepared from autoclaved sol. J Sol-Gel Sci Technol 32:161–165

Hitoshi I, Shunsuke N, Tsuyoshi M et al (2008) Preparation of MgF2-SiO2 thin films with a low refractive index by a sol-gel process. Appl Opt 13(47):200–205

Wojciechowska M, Czajka B, Pietrowski M et al (2000) MgF2 as a non-conventional catalytic support. Surface and structure characterization. Catal Lett 66(3):147–153

Zhu YF, Shi L, Liang J et al (2008) Synthesis of zirconia nanoparticles on carbon nanotubes and their potential for enhancing the fracture toughness of alumina ceramics. Compos: Part B 39:1136–1141

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, FY., Zhu, YF., Jiang, Y. et al. Fabrication and properties of MgF2 composite film modified with carbon nanotubes. J Sol-Gel Sci Technol 58, 587–593 (2011). https://doi.org/10.1007/s10971-011-2431-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-011-2431-x