Abstract

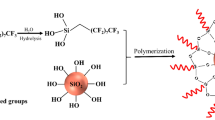

Ambient-curable polysiloxane coatings were prepared by hydrolysis and condensation of 3-methacryloxypropylmethyldimethoxysilane (MPDS) and methyltriethoxysilane (MTES) and subsequently mixing with 3-aminopropyltriethoxysilane (APS). The structures of the as-obtained polysiloxane oligomers as well as the dried polysiloxane coatings on tinplate substrates were analyzed by FTIR and 29Si NMR. The mechanical properties of the coatings were thoroughly examined at both macro-level and micro-level using a pendulum hardness rocker, an impact tester, and a nanoindentation/nanoscratch instrument. Effects of the molar ratio of MPDS/MTES, the dosage of aqueous ammonia solution, and the catalytic condition on the structure of polysiloxane oligomers as well as the structure and mechanical properties of the polysiloxane coatings were investigated. The dried coatings with thickness of 15–26 μm are highly elastic. The hardness (Koenig hardness and microhardness), impact resistance and scratch resistance are mainly dependent on the condensation degree of polysiloxane coatings rather than on the organic component of the coatings. A proper pre-hydrolysis process or more APS is benefit for enhancing the mechanical strength of the polysiloxane coatings. Polysiloxane coatings with high hardness and excellent scratch resistance can be prepared preferentially at low molar ratio of MPDS/MTES.

Similar content being viewed by others

References

Mélanie F, Habiba M, Brice G, Jean-Philippe B (2001) J Non-Cryst Solids 293–295:527–533

Dave BC, Hu XK, Devaraj Y, Dhali SK (2004) J Sol–Gel Sci Technol 32:143–147

Subasri R, Jyothirmayi A, Reddy DS (2010) Surf Coat Technol 205:806–813

Ying-Sing L, Paul BW, Rosalyn P, Tuan T (2004) Spectrochim Acta Part A 60:2759–2766

Ying-Sing L, Yu W, Tuan T, Anshion P (2005) Spectrochim Acta Part A 61:3032–3037

Ying-Sing L, Abdul B (2008) Spectrochim Acta Part A 70:1013–1019

Wolfgang EG, Hansala T, Selma H, Matthias P, Andreas K, Gerhard Z, Gerhard EN (2006) Surf Coat Technol 200:3056–3063

Ivan J, Boris O, Angela ŠV, Matjaž K, Janez K (2010) Thin Solid Films 518:2710–2721

Malzbender J, With G (2001) Surf Coat Technol 135:202–207

Nemeth S, Liu YC (2009) Thin Solid Films 517:4888–4891

Mehner A, Dong J, Prenzel T, Datchary W, Lucca DA (2010) J Sol–Gel Sci Technol 54:355–362

Josefina B, Damián AL, Ana LC (2009) Wear 266:1165–1170

Walid AD, John HX, Tao X (2004) J Am Ceram Soc 87:1782–1784

Mackenzie JD, Bescher EP (2000) J Sol–Gel Sci Technol 19:23–29

Wang H, Robert A (2007) Corros Sci 49:4491–4503

Xing W, You B, Wu LM (2008) J Coat Technol Res 5:65–72

Xing W, You B, Wu LM (2007) J Sol–Gel Sci Techn 42:187–195

Huang Y, Liu W (2010) J Sol–Gel Sci Technol 55:261–268

Sarmento V, Schiavetto M, Hammer P, Benedetti A, Fugivara C, Suegama PH, Pulcinelli SH, Santilli CV (2010) Surf Coat Technol 204:2689–2701

Spirkova M, Brus J, Hlavata D, Kamisova H, Matejka L, Strachota A (2004) J Appl Polym Sci 92:937–950

Donley MS, Mantz RA, Khramov AN, Balbyshev VN, Kasten LS, Gaspar DJ (2003) Prog Org Coat 47:401–415

Innocenzi P, Brusatin G, Licoccia S, Vona M, Babonneau F, Bruno A (2003) Chem Mater 15:4790–4797

Pharr GM, Oliver WC, Brotzen FR (1992) J Mater Res 7:1564–1583

Osterholtz FD, Pohl ER (1992) J Adhes Sci Technol 6:127–149

Ferchichi A, Calas-Etienne S, Smaı¨hi M, Pre′vot G, Solignac P, Etienne P (2009) J Mater Sci 44:2752–2758

Hideki K, Yoshiaki H, Atsushi S, Kazuyuki K (2008) Chem Asian J 3:600–606

Chen GD, Zhou SX, Gu GX, Wu LM (2005) Macromol Chem Phys 206:885–892

Liu WC, Yang CC, Chen WC, Dai BT, Tsai MS (2002) J Non-Cryst Solids 311:233–240

Han YH, Taylor A, Mantle MD, Knowles KM (2007) J Sol–Gel Sci Technol 43:111–123

Mather BD, Viswanathan K, Miller KM, Long TE (2006) Prog Polym Sci 31:487–531

Acknowledgments

This work was supported by the Foundation of Science and Technology of Shanghai (09DJ1400205), Shanghai Shuguang Scholar Program (09SG06), Nature Science Foundation of China (51073038) and the innovative team of Ministry of Education of China (IRT0911).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, X., Zhou, S., You, B. et al. Ambient-curable polysiloxane coatings: structure and mechanical properties. J Sol-Gel Sci Technol 58, 490–500 (2011). https://doi.org/10.1007/s10971-011-2418-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-011-2418-7