Abstract

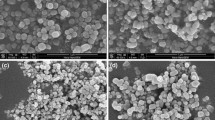

The optimum pH range for synthesizing barium strontium titanate (Ba0.5Sr0.5TiO3, BST) nanopowders by sol–gel auto-combustion method was calculated based on the principles of matter balance and charge balance. The effectiveness of the calculation was proved by the successful synthesis of highly dispersive, spherically shaped and pure BST nanoparticles with setting the pH in the range pre-decided by theoretical evaluation. Ours might have provided an effective path for pre-deciding the solution pH in synthesizing various oxide nanopowders by sol–gel auto-combustion method.

Similar content being viewed by others

References

Beitel G, Wendt H, Fritch E, Weinrich V, Engelhardt M (1999) Microelectron Eng 48:299

Horng RH, Wuu DS, Kung CY, Lin JC, Leu CC, Haung TY, Sze SM (2001) J Non-Cryst Solids 280:48

Zhang TJ, Ni H (2002) Sens Actuators A 100:252

Chen XF, Zhu WG, Tan OK (2000) Mater Sci Eng B 77:177

Zhu W, Tan OK, Yan Q, Oh JT (2000) Sens Actuators B 65:366

Jain M, Majumder SB, Katiyar RS, Bhalla AS (2003) Mater Lett 57:4232

Xu J, Menesklou WG, Tiffee EI (2004) J Eur Ceram Soc 24:1735

Szymczak L, Ujma Z, Handerek J, Kapusta J (2004) Ceram Int 30:1003

Tian HY, Luo WG, Pu XH, He XY, Qiu PS, Ding AL (2001) Mater Chem Phys 69:166

Jang SI, Jang HM (1998) Thin Solid Film 330:89

Khollam YB, Bhoraskar SV, Deshpande SB, Potdar HS, Pavaskar NR, Sainkar SR, Date SK (2003) Mater Lett 57:1871

Ries A, Simoes AZ, Cilense M, Zaghete MA, Varela JA (2003) Mater Charact 50:217

Qi XW, Zhou J, Yue ZX, Gui ZL, Li LT (2003) Ceram Int 29:347

Liu BH, Ding J (2006) Appl Phys Lett 88:042506

Choy J-H, Han Y-S, Hwang S-H (1998) J Am Ceram Soc 81:3197

Choy J-H, Han Y-S, Song S-W (2004) Mater Lett 19:257

Choy J-H, Han Y-S (1997) Mater Lett 32:209

Acknowledgements

This work was supported by National Natural Science Foundation of China (No. 10574112). Guangxi Natural Science Fund, China (Grant No. 0832257) and the Research Foundation of Education Bureau of Guangxi Province, China (Grant No. 200708LX333).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, S.H., Hu, J., Xu, H.J. et al. The calculation of the optimum pH range for synthesizing BST nanopowders by sol–gel auto-combustion process. J Sol-Gel Sci Technol 49, 166–169 (2009). https://doi.org/10.1007/s10971-008-1852-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-008-1852-7