Abstract

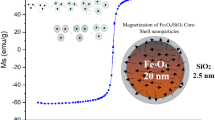

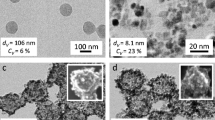

This paper describes a method for fabricating spherical submicron-sized silica particles that contained magnetite nanoparticles (magnetite/silica composite particles). The magnetite nanoparticles with a size of ca. 10 nm were prepared according to the Massart method, and were surface-modified with carboxyethylsilanetriol. The fabrication of magnetite/silica composite particles was performed in water/ethanol solution of tetraethoxyorthosilicate with ammonia catalyst in the presence of the surface-modified magnetite nanoparticles. The magnetite/silica composite particles with a size of ca. 100 nm were successfully prepared at 0.05 M TEOS, 15 M water, and 0.8 M ammonia with injection of the magnetite nanoparticle colloid at 2 min after the initiation of hydrolysis reaction of TEOS. Magnetite concentration in the composite particles could be raised to 17.3 wt.% by adjustment of the injected amount of the magnetite colloid, which brought about the saturation magnetization of 7.5 emu/g for the magnetite/silica composite particles.

Similar content being viewed by others

References

Cupta PK, Hung CT (1989) Life Sci 44:175

Mitsuhashi K, Yoshizaki R, Okada H, Ohara T, Wada H (2003) Bunseki Kagaku 53:121 (in Japanese)

Uhlen M (1989) Nature 340:733

Kondo A, Kamura H, Higashitani K (1994) Appl Microbiol Biotechnol 41:99

Haik Y, Pai V, Chen CJ (1999) J Magn Magn Mater 194:254

Yang HH, Zhang SQ, Chen XL, Zhuang ZX, Xu JG, Wang XR (2004) Anal Chem 76:1316

Santra S, Tapec R, Theodoropoulou N, Dobson J, Hebard A, Tan W (2001) Langmuir 17:2900

Barnakov YA, Yu MH, Rosenzweig Z (2005) Langmuir 21:7524

Liu X, Xing J, Guan Y, Shan G, Liu H (2004) Colloids Surf A 238:127

Sun Y, Duan L, Guo Z, DuanMu Y, Ma M, Xu L, Zhang Y, Gu N (2005) J Magn Magn Mater 285:65

Correa-Duarte MA, Giersig M, Kotov NA, Liz-Marzán LM (1998) Langmuir 14:6430

Lu Y, Yin Y, Mayers BT, Xia Y (2002) Nano Lett 2:183

Deng YH, Wang CC, Hu JH, Yang WL, Fu SK (2005) Colloids Surf A 262:87

Gu S, Onishi J, Kobayashi Y, Nagao D, Konno M (2005) J Colloid Interface Sci 289:419

Kobayashi Y, Yoshida M, Nagao D, Ando Y, Miyazaki T, Konno M (2007) Ceram Trans 198:135

Nagao D, Osuzu H, Yamada A, Mine E, Kobayashi Y, Konno M (2004) J Colloid Interface Sci 279:143

Massart R (1981) IEEE Trans Magn 17:1247

Shimoiizaka J, Nakatsuka K, Chubachi R, Sato Y (1976) Nihon Kagakukaishi 1:6 (in Japanese)

Wang Q, Wei Q, Gu H (2003) J Chem Eng Jpn 36:1227

Harris LA, Goff JD, Carmichael AY, Riffle JS, Harburn JJ, St. Pierre TG, Saunders M (2003) Chem Mater 15:1367

Mine E, Konno M (2001) J Chem Eng Jpn 34:545

Xu H, Tong N, Cui L, Lu Y, Gu H (2007) J Magn Magn Mater 311:125

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kobayashi, Y., Saeki, S., Yoshida, M. et al. Synthesis of spherical submicron-sized magnetite/silica nanocomposite particles. J Sol-Gel Sci Technol 45, 35–41 (2008). https://doi.org/10.1007/s10971-007-1648-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-007-1648-1