Abstract

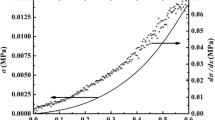

The bending strength and the Young’s modulus of bimodal porous silica gels having different porosity were evaluated. The porosity of the gel increased by aging the gel under basic conditions, and decreased with increasing the calcination temperature. The mesopores disappeared on calcination at 1,050 °C, whereas continuous macropores retained their morphology up to 1,050 °C for all the samples. Both the bending strength and the Young’s modulus of the bimodal porous silica gels were expressed as power-law functions of the bulk density, and no effect of bimodal pore structures on mechanical properties was observed. We also found linear correlation between the bending strength and the elasticity. The bimodal porous silica had higher strength and elastic modulus compared with other porous materials at the same porosity probably due to the presence of homogeneous micrometer-scale macropores.

Similar content being viewed by others

References

Nakanishi K, Soga N (1991) J Am Ceram Soc 74:2518

Nakanishi K (1997) J Porous Mater 4:67

Takahashi R, Sato S, Sodesawa T, Haga A, Nishino H (2004) J Ceram Soc Japan 112:99

Minakuchi H, Nakanishi K, Soga N, Ishizuka N, Tanaka N (1996) Anal Chem 68:3498

Nakamura N, Takahashi R, Sato S, Sodesawa T, Yoshida S (2000) Phys Chem Chem Phys 2:4983

Takahashi R, Sato S, Sodesawa T, Yachi A (2001) J Ceram Soc Japan 109:577

Martin J, Hosticka B, Lattimer C, Norris PM (2001) J Non-Cryst Solids 285:222

Coble RL, Kingery WD (1956) J Am Ceram Soc 39:377

Mercier F, Kolenda F, Puiggali JR (2002) Chem Eng J 86:95

Isobe T, Tomita T, Kameshima Y, Nakajima A, Okada K (2006) J Euro Ceram Soc 26:957

Spriggs RM, Vasilos T (1963) J Am Ceram Soc 46:224

Ryshkrwitch E (1953) J Am Ceram Soc 36:65

Fryxell RE, Chandler BA (1964) J Am Ceram Soc 47:283

Knudsen FP (1959) J Am Ceram Soc 42:376

Colombo P, Hellmann JR, Shelleman DL (2001) J Am Ceram Soc 84:2245

Studt PL, Fulrath RM (1962) J Am Ceram Soc 45:182

Huec JCL, Schaeverbeke T, Clement D, Faber J, Rebeller AL (1995) Biomaterials 16:113

Girona MM, Martinez E, Roig A, Esteve J, Mokins E (2001) J Non-Cryst Solids 285:244

Woignier T, Phalippou J, Hdach H, Larnac G, Pernot F, Scherer G (1992) J Non-Cryst Solids 147&148:672

Woignier T, Reynes J, Hafidi Alaoui A, Beurroies I, Phalippou J (1998) J Non-Cryst Solids 241:45

Gross J, Fricke J (1995) Nanostruct Mater 6:905

Pekara R, Alviso C, Lu X, Gross J, Fricke J (1995) J Non-Cryst Solids 188:34

Scherer G (1997) J Non-Cryst Solids 215:155

Takahashi R, Sato S, Sodesawa T, Goto T, Matsutani K, Mikami N (2005) Mater Res Bull 40:1148

Takahashi R, Sato S, Sodesawa T, Goto T, Matsutani K, Mikami N (2007) Mater Res Bull 42:523

Yachi A, Takahashi R, Sato S, Sodesawa T, Matsutani K, Mikami N (2005) J Non-Cryst Solids 351:331

Takahashi R, Nakanishi K, Soga N (1995) Faraday Discuss 101:249

Duckworth W (1953) J Am Ceram Soc 36:68

Kingery W, Bowen H, Uhlmann D (1976) Introduction to ceramics, 2nd edn. John Wiley and Sons, New York

Zou X, Toratani H (2001) J Non-Cryst Solids 290:180

Acknowledgement

This work was supported by Industrial Research Grant Program in 04A25503c from New Energy and Industrial Technology Development Organization (NEDO) of Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shinozaki, N., Takahashi, R., Sato, S. et al. Strength and elasticity of bimodal porous silica prepared from water glass. J Sol-Gel Sci Technol 43, 275–282 (2007). https://doi.org/10.1007/s10971-007-1589-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-007-1589-8