Abstract

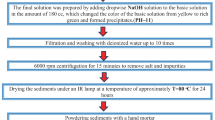

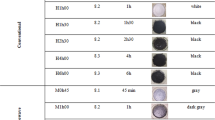

Tin oxide-doped hybrid particles were prepared by a wet chemical process with organic-inorganic (phenyl/silica) hybrid particles in an alcoholic solution. The phenyl/silica hybrid particles, with a diameter of ca. 790 nm were used as a new support material for tin oxide (SnO2) particles from tin(IV) chloride. The surface of the particles was modified via nitration of aromatic groups in the particles, to promote formation of the tin oxide coating on the particles. The thickness and surface morphology of the tin oxide layer coated on the nitrated-phenyl/silica hybrid particles could be controlled by varying the tin(IV) chloride concentration and reaction time. The size and morphology of the resultant particles were investigated with field emission scanning electron microscopy (FE-SEM) and transmission electron microscopy (TEM). The particles obtained were also characterised by infrared (FTIR) and solid-state 13C magic angle spinning nuclear magnetic resonance (13C-CP/MAS NMR) spectroscopy. The effect of processing parameters on the crystallinity and structure of the doped hybrids were confirmed by X-ray diffraction (XRD) patterns.

Similar content being viewed by others

References

H. Ogawa, A. Abe, M. Nishikawa, and S. Hayakawa, J. Electrochem. Soc. 128, 2020 (1981).

Z. Jarzebski and J.P. Marton, J. Electrochem. Soc. 123, 299c (1976).

H. Takeo, A. Shunji, S. Yasuhiro, and E. Makoto, Sensors and Actuators B. 93, 590 (2003).

H. J. Hah, J. S. Kim, B. J. Jeon, S. M. Koo, and Y. E. Lee, Chem Comm., 1712 (2003).

C.J. Brinker and G.W. Scherer, Sol–Gel Science (Academic Press, New York, 1990).

W. Stöber, A. Fink, and E. Bohn, J. Colloid Interface Sci. 26, 62 (1968).

J. Zhu, Z. Lu, S.T. Aruna, D. Aurbach, and A. Gedanken, Chem. Mater. 12, 2557 (2000).

S.W. Dien and L.W. Nae, J. Mater. Res. 15, 1445 (2000).

H. Klug and L. Alexander (eds.), X-ray Diffraction Procedure (Willey, New York, 1962), p. 125.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jung, C.Y., Hah, H.J., Han, S.H. et al. Preparation of Tin Oxide-Based Metal Oxide Particles. J Sol-Gel Sci Technol 33, 81–85 (2005). https://doi.org/10.1007/s10971-005-6704-0

Issue Date:

DOI: https://doi.org/10.1007/s10971-005-6704-0