Abstract

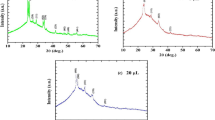

The photo-induced hydrophilicity of TiO2 films deposited on stainless steel substrates and silicon wafers using two different sol-gel routes has been investigated. The results indicate that crystalline titanium oxide films with excellent hydrophilic properties can be obtained on silicon wafer with both routes. XPS and XRD data reveal that films deposited on stainless steel exhibit crystallization features similar to those of films deposited on silicon wafers, and only differ by their oxidation degree owing to a TiO2 reduction process associated to a diffusion of iron ions during deposition of the acidic sol and/or high temperature post-treatment. Consequently, hydrophilic properties of films deposited on stainless steel are inhibited. The deposition of a SiO x barrier layer at the film/substrate interface allows preventing such a detrimental substrate influence. A low temperature deposition route of the TiO2 film associated to the presence of a barrier layer yields best results in preventing iron contamination of the films.

Similar content being viewed by others

References

A. Fujishima and K. Honda, Nature 238, 37 (1972).

R. Wang, N. Sakai, and A. Fujishima, J. Phys. Chem. B 103, 2188 (1999).

N. Sakai, A. Fujishima, and T. Wanatabe, J. Phys. Chem B 105, 3023 (2001).

T. Wanatabe, A. Nakajima, and R. Wang, Thin Solid Films 351, 260 (1999).

X.P. Wang, Y. Yu, and X.F. Hu, Thin Solid Films 371, 148 (2000).

J. Yu, X. Zhao, and Q. Zhao, Mater. Chem. Phys. 69, 25 (2001).

R. Sun, A. Nakajima, and A. Fujishima, J. Phys. Chem B 105, 1984 (2001).

J.C. Yu, J. Yu, H.Y. Tang, and L. Zhang, J. Mater. Chem. 12, 81 (2002).

Y. Ohko, S. Saitoh, and T. Tatsuma, J. Electrochem. Soc. 148, B24 (2001).

A. Fernandez, G. Lassaletta, and V.M. Jimenez, Apply. Catal. B: Environ. 7, 49 (1995).

J.M. Hermann, Catalysis Today 54, 131 (1999).

H.C. Chan, J.F. Porter, and J.P. Barford, J. Mater. Res. 17, 1758 (2002).

Y. Zhu, L. Zhang, and L. Wang, J. Mater. Chem. 11, 1864 (2001).

J. Yu, W. Ho, and J. Lin, Environ. Sci. Tech. 37, 2296 (2003).

T. Wanatabe, S. Fukayama, and M. Miyauchi, J. Sol-Gel Sci. Tech. 19, 71 (2000).

A. Hattori, K. Shimoda, and H. Tada, Langmuir 15, 5422 (1999).

M. Langlet, M. Burgos, and C. Coutier, J. Sol-Gel Sci. Tech. 22, 139 (2001).

M. Langlet, A. Kim, and M. Audier, J. Mater. Sci. 38, 3945 (2003).

R.J. Gonzales, R. Zallen, and H. Berger, Phys. Rev. B. 55, 7014 (1997).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Permpoon, S., Fallet, M., Berthomé, G. et al. Photo-Induced Hydrophilicity of TiO2 Films Deposited on Stainless Steel via Sol-Gel Technique. J Sol-Gel Sci Technol 35, 127–136 (2005). https://doi.org/10.1007/s10971-005-1385-2

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10971-005-1385-2