Abstract

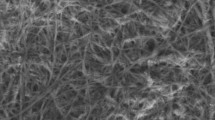

Electrospun fiber mats are promising media for chemical separation because of their porous interior and high surface area, which enhance penetrant permeation and provide a large number of active sites. The application of this technology was fulfilled in the present study, wherein syndiotactic polystyrene (sPS) fibers were prepared by high-temperature solution electrospinning to absorb volatile organic compounds. The as-spun sPS fibers had an average radius of ~360 nm and were amorphous as revealed by Fourier transform infrared spectroscopy (FTIR) and wide-angle X-ray diffraction. When the electrospun fibers were exposed to different solvent vapors, solvent-induced crystallization occurred in these submicron-sized fibers to form δ- or γ-form sPS crystals, depending on the solvent used. To trace the microstructure transformation of sPS chains induced by the solvent vapors, in situ FTIR spectral measurements were performed. The absorbance of crystallization-sensitive IR bands was plotted against time, from which the crystallization kinetics were analyzed based on the Avrami equation. Results showed that the rate of solvent-induced crystallization was higher for solvents with a higher saturated vapor pressure. Subsequent solvent desorption from the crystallized sPS fibers was also studied under ambient conditions by monitoring the absorbance variation of the solvent-sensitive IR band. Two-stage solvent desorption was observed in the δ-form sPS fibers; this process consisted of initial rapid desorption from the amorphous region, followed by slow desorption from the crystalline region. Notably, all the solvent molecules in the treated fibers can be completely removed in this manner, thereby leading to the formation of δ e-form crystals for repetitive sorption/desorption applications.

Similar content being viewed by others

References

Gowd EB, Tashiro K, Ramesh C (2009) Prog Polym Sci 34:280–315

Milano G, Guerra G (2009) Prog Mater Sci 54:68–88

Chatani Y, Shimane Y, Inagaki T, Ijitsu T, Yukinari T, Shikuma H (1993) Polymer 34:1620–1624

Rizzo P, Albunia AR, Guerra G (2005) Polymer 46:9549–9554

Milano G, Venditto V, Guerra G, Cavallo L, Ciambelli P, Sannino D (2001) Chem Mater 13:1506–1511

Uda Y, Kaneko F, Kawaguchi T (2004) Polymer 45:2221–2229

Ma W, Yu J, He J (2005) Macromolecules 38:4755–4760

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S (2003) Compos Sci Technol 63:2223–2253

Reneker DH, Yarin AL (2008) Polymer 49:2387–2425

Greiner A, Wendorff JH (2007) Angew Chem Int Ed 46:5670–5703

Zhu H, Qiu S, Jiang W, Wu D, Zhang C (2011) Environ Sci Technol 45:4527–4531

Bertarelli C, Zanutta A, Bianco A, Daniel C (2011) Soft Mater 9:303–312

Givens SR, Gardner KH, Rabolt JF, Chase DB (2007) Macromolecules 40:608–610

Rein DM, Shavit-Hadar L, Khalfin RL, Cohen Y, Shuster K, Zussman E (2007) J Polym Sci Polym Phys 45:766–773

Yoshioka T, Dersch R, Tsuji M, Schaper AK (2010) Polymer 51:2383–2389

Cheng Y, Lu H, Wang Y, Thierry A, Lotz B, Wang C (2010) Macromolecules 43:2371–2376

Tashiro K, Ueno Y, Yoshioka A, Kobayashi M (2001) Macromolecules 34:310–315

Yoshioka A, Tashiro K (2003) Polymer 44:6681–6688

Brandrup J, Immergut EH (1989) Polymer handbook, 3rd ed. Wiley-Interscience, New York, sec. III

Durning CJ, Rebenfeld WB, Russel WB, Weigmann HD (1986) J Polym Sci Polym Phys 24:1321–1340

Ouyang H, Lee WH, Shih MC (2002) Macromolecules 35:8428–8432

Wunderlich B (1976) Macromolecular physics, Vol. 2. Academic, New York

Gowd EB, Shibayama N, Tashiro K (2008) Macromolecules 41:2541–2547

Ritger PL, Reppas NA (1987) J Contrl Release 5:23–36

Wang TT, Kwei TK (1973) Macromolecules 6:919–921

Bernes AR, Hopfenberg HB (1982) J Membr Sci 10:283–303

Venditto V, Del Mauro ADG, Mensitieri G, Milano G, Musto P, Rizzo P, Guerra G (2006) Chem Mater 18:2205–2210

Gowd EB, Tashiro K (2007) Macromolecules 40:5366–5371

Gowd EB, Shibayama N, Tashiro K (2006) Macromolecules 39:8412–8418

Vrentas JS, Jarzebski CM, Duda JL (1975) AIChE J 21:894–901

Durning CJ, Rebenfeld L, Russel WB, Weigmann HD (1986) J Polym Sci Polym Phys 24:1341–1360

Acknowledgments

This work was supported by the Ministry of Science and Technology of Taiwan (NSC96-2918-I-006-011 and MOST103-2221-E-006-262-MY3).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Avrami plots of solvent-treated fibers.

Figure S1

(DOC 120 kb)

Rights and permissions

About this article

Cite this article

Cheng, YW., Wang, C. Solvent-induced crystallization of electrospun syndiotactic polystyrene nanofibers and its reversible desorption/sorption of volatile organic vapors. J Polym Res 23, 234 (2016). https://doi.org/10.1007/s10965-016-1130-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-016-1130-2