Abstract

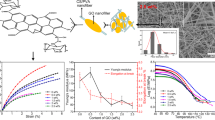

This article is aimed at a basic physical characterization of electrospun PVDF/graphene oxide (GO) composite non-woven fibre mats. The morphological characterization of the prepared fabrics was performed via SEM investigations. Introduction of the GO during the electrospinning process caused significant changes in the crystalline structure of PVDF, and a transformation from α- to β-crystalline phases was achieved. Addition of the GO particles into PVDF did not only improve the thermal stability of the polymer, but also acted as a reinforcing filler, giving rise to improved dynamic moduli and tensile strength. The dielectric properties were evaluated over a broad frequency range, and it was confirmed that the presence of small amounts of GO had little effect on the dielectric properties of the PVDF, since the GO has a dielectric character similar to that of the PVDF.

Similar content being viewed by others

References

Huang L, Lu C, Wang F, Wang L (2014) Preparation of PVDF/graphene ferroelectric composite films by in situ reduction with hydrobromic acids and their properties. RSC Adv 4:45220–45229

Chang C, Van Tran H, Wang J, Fuh Y-K, Lin L (2010) Direct-write piezoelectric polymeric nanogenerator with high energy conversion efficiency. Nano Lett 10:726–731

Zang W-b, Xu X-l, Yang J-h, Hiuang T, Zhang N, Wang Y, Zhou Z-w (2015) High thermal conductivity of poly(vinylidene fluoride)/carbon nanotubes nanocomposites achieved by adding polyvinylpyrrolidone. Compos Sci Technol 106:1–8

Shao H, Fang J, Wang H, Lin T (2015) Effect of electrospinning parameters and polymer concentrations on mechanical-to-electrical energy conversion of randomly-oriented electrospun poly(vinylidene fluoride) nanofiber mats. RSC Adv 5:14345–14350

Martins P, Lopes AC, Lanceros-Mendez S (2014) Electroactive phases of poly(vinylidene fluoride): determination, processing and applications. Prog Polym Sci 39:683–706

Maji S, Sarkar PK, Aggarwal L, Ghosh SK, Mandal D, Sheet G, Acharya S (2015) Self-oriented beta-crystalline phase in the polyvinylidene fluoride ferroelectric and piezo-sensitive ultrahin Langmuir-Schaefer film. Phys Chem Chem Phys 17:8159–8165

Li L, Zhang M, Rong M, Ruan W (2014) Studies on the transformation process of PVDF from alpha to beta phase by stretching. RSC Adv 4:3938–3943

Liu G, Schneider K, Zheng L, Zhang X, Li C, Stamm M, Wang D (2014) Stretching induced phase separation in poly(vinylidene fluoride)/poly(butylene succinate) blends studies in-situ X-ray scattering. Polymer 55:2588–2596

Sharma M, Madras G, Bose S (2014) Process induced electroactive beta-polymorph in PVDF: effect on dielectric and ferroelectric properties. Phys Chem Chem Phys 16:14792–14799

Kim GH, Hong SM, Seo Y (2009) Piezoelectric properties of poly(vinylidene fluoride) and carbon nanotube blends: beta-phase development. Phys Chem Chem Phys 11:10506–10512

Lei T, Cai X, Wang X, Yu L, Hu X, Zheng G, Lv W, Wang L, Wu D, Sun D, Lin L (2013) Spectroscopic evidence for high fraction of ferroelectric phase induced in electrospun polyvinylidene fluoride fibers. RSC Adv 3:24952–24958

Fang J, Wang X, Lin T (2011) Electrical power generator from randomly oriented electrospun poly(vinylidene fluoride) nanofibre membranes. J Mater Chem 21:11088–11091

Mofokeng TG, Luyt AS, Pavlovic VP, Pavlovic VB, Dudic D, Vlahovic B, Djokovic V (2014) Ferroelectric nanocomposites of polyvinylidene fluoride/polymethyl methacrylate blend and BaTiO3 particles: fabrication of β-crystal polymorph rich matrix through mechanical activation of the filler. J Appl Phys 115:084109

Zhang YY, Jiang SL, Yu Y, Zeng YK, Zhang GZ, Zhang QF, He JG (2012) Crystallization behavior and phase-transformation mechanism with the use of graphite nanosheets in poly(vinylidene fluoride) nanocomposites. J Appl Polym Sci 125:E314–E319

Thangavel E, Ramasundaram S, Pitchaimuthu S, Hong SW, Lee SY, Yoo SS, Kim D-E, Ito E, Kang YS (2014) Structural and tribological characteristics of poly(vinylidene fluoride)/functionalized graphene oxide nanocomposite thin films. Compos Sci Technol 90:187–192

Jia N, Xing Q, Xia G, Sun J, Song R, Huang W (2015) Enhanced beta-crystalline phase in poly(vinylidene fluoride) films by polydopamine-coated BaTiO3 nanoparticles. Mater Lett 139:212–215

Guan X, Zhang Y, Li H, Ou J (2013) PZT/PVDF composites doped with carbon nanotubes. Sensors Actuators A Phys 194:228–231

Jaleh B, Fakhri P, Noroozi M, Muensit N (2012) Influence of copper nanoparticles concentration on the properties of poly(vinylidene fluoride)/Cu nanoparticles nanocomposite films. J Inorg Organomet Polym Mater 22:878–885

Vasundhara K, Mandal BP, Tyagi AK (2015) Enhancement of dielectric permittivity and ferroelectricity of a modified cobalt nanoparticle and polyvinylidene fluoride based composite. RSC Adv 5:8591–8597

An N, Liu H, Ding Y, Zhang M, Tang Y (2011) Preparation and electroactive properties of a PVDF/nano-TiO2 composite film. Appl Surf Sci 257:3831–3835

Jaleh B, Jabbari A (2014) Evaluation of reduced graphene oxide/ZnO effect on properties of PVDF nanocomposite films. Appl Surf Sci 320:339–347

Kenneth JL, Donghee C (2011) Zinc oxide nanoparticle-polymeric thin films for dynamic strain sensing. J Mater Sci 46:228–237

Li Z, Zhang X, Li G (2014) In situ ZnO nanowire growth to promote the PVDF pieto phase and the ZnO-PVDF hybrid self-rectified nanogenerator as a touch sensor. Phys Chem Chem Phys 16:5475–5479

Fang L, Wu W, Hiuang X, He J, Jiang P (2015) Hydrangea-like zinc oxide superstructures for ferroelectric polymer composites with high thermal conductivity and high dielectric constant. Compos Sci Technol 107:67–74

El Achaby M, Arrakhiz FZ, Vaudreuil S, Essassi EM, Qaiss A (2012) Piezoelectric β-polymorph formation and properties enhancement in graphene oxide – PVDF nanocomposite films. Appl Surf Sci 258:7668–7677

Liu S, Zeng TH, Hofmann N, Burcombe E, Wei J, Jiang R, Kong J, Chen Y (2011) Antibacterial activity of graphite, graphite oxide, graphene oxide, and reduced graphene oxide: membrane and oxidative stress. J Am Chem Soc 5:6971–6980

Wang Z, Yu H, Xia J, Zhang F, Li F, Xia Y, Li Y (2012) Novel GO-blended PVDF ultrafiltration membranes. Desalination 299:50–54

Meng Q-L, Liu H-C, Huang Z, Kong S, Lu X, Tomkins P, Jiang P, Bao X (2016) Mixed conduction properties of pristine bulk graphene oxide. Carbon 101:338–344

Ponnamma D, Guo Q, Krupa I, Al-Maadeed MASA, Varughese KT, Thomas S, Sadasivuni KK (2015) Graphene and graphitic derivative filled polymer composites as potential sensors. Phys Chem Chem Phys 17:3954–3981

Noorunnisa K, Deepalekshmi P, Al-Maadeed MA (2015) In: Kishor KS (ed) Graphene-based polymer nanocomposites in electronics. Springer International Publishing, Switzerland

Issa AI, Al-Maadeed M, Luyt AS, Mrlik M, Hassan MK (2016) Investigation of the physico-mechanical properties of electrospun PVDF/cellulose (nano)fibers. J Appl Polym Sci 133:43594

Won-Chun O, Chin ML, Zhang K, Zhang F-J, Jang W-K, Zhang F-J (2010) The effect of thermal and ultrasonic treatment on the formation of graphene-oxide nanosheets. J Korean Phys Soc 56:1097–1102

Szabo T, Berkesi O, Forgo P, Josepovits K, Sanakis Y, Petridis D, Dekany I (2006) Evolution of surface functional groups in a series of progressively oxidized graphite oxides. Chem Mater 18:2740–2749

Kudin KN, Ozbas B, Schniep HC, Prud’homme RK, Aksay IA, Car R (2008) Raman spectra of graphite oxide and functionalized graphene sheets. Nano Lett 8:36–41

Guerrero-Contreras J, Caballero-Briones F (2015) Graphene oxide powders with different oxidation degree, prepared by synthesis variations of the Hummers method. Mater Chem Phys 153:209–220

Kumar HV, Woltornist SJ, Adamson DH (2016) Fractionation and characterization of graphene oxide by oxidation extent through emulsion stabilization. Carbon 98:491–495

Krishnamoorthy K, Veerapandian M, Yun K, Kim S-J (2013) The chemical and structural analysis of graphene oxide with different degrees of oxidation. Carbon 53:38–49

Konios D, Stylianakis MM, Stratakis E, Kymakis E (2014) Dispersion behaviour of graphene oxide and reduced graphene oxide. J Colloid Interface Sci 430:108–112

Dimiev AM, Tour JM (2014) Mechanism of graphene oxide formation. ACS Nano 8:3060–3068

Park YJ, Kang YS, Park C (2005) Micropatterning of semicrystalline poly(vinylidene fluoride) (PVDF) solutions. Eur Polym J 41:1002–1012

Zhang WL, Liu YD, Choi HJ, Kim SG (2012) Electrorheology of graphene oxide. ACS Appl Mater Interfaces 4:2267–2272

Najafi F, Rajabi M (2015) Thermal gravity analysis for the study of stability of graphene oxide–glycine nanocomposites. Int Nano Lett 5:187–190

Stapler JT, Barnes WJ, Yelland WEC (1968) Thermal degradation of polyvinylidene fluoride and polyvinyl fluoride by oven pyrolysis. Technical Report 69-7-CM, Clothing and Organic Materials Laboratory, US Army Natick Laboratories

Al-Maadeed MA, Shabana YM, Noorunnisa Khanam P (2014) Processing. characterization and modeling of recycled polypropylene/glass fibre/wood flour composites. Mater Des 58:374–380

Ourry L, Marchesini S, Bibani M, Mercone S, Ammar S, Mammeri F (2015) Influence of nanoparticle size and concentration on the electroactive phase content of PVDF in PVDF-CoFe2O4-based hybrid films. Phys Status Solidi A 212:252–258

Ilcikova M, Mrlik M, Sedlacek T, Chorvat D, Krupa I, Slouf M, Koynof K, Mosnacek J (2014) Viscoelastic and photo-actuation studies of composites based on polystyrene-grafted carbon nanotubes and styrene-b-isoprene-b-styrene block copolymer. Polymer 55:211–218

Ilcikova M, Mrlik M, Sedlacek T, Slouf M, Zhigunov A, Koynov K, Mosnacek J (2014) Synthesis of photoactuating acrylic thermoplastic elastomers containing diblock copolymer-grafted carbon nanotubes. ACS Macro Lett 3:999–1003

Ni P, Li H, Yang M, He X, Li Y, Liu Z-H (2010) Study on the assembling reaction of graphite oxide nanosheets and polycations. Carbon 48:2100–2105

Acknowledgments

This article was made possible by student grant (QUST-CAM-FALL-14/15-1) from the College of Arts and Sciences at Qatar University. The statements made herein are solely the responsibility of the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Issa, A.A., Al-Maadeed, M.A.A.S., Mrlík, M. et al. Electrospun PVDF graphene oxide composite fibre mats with tunable physical properties. J Polym Res 23, 232 (2016). https://doi.org/10.1007/s10965-016-1126-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-016-1126-y