Abstract

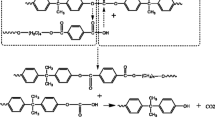

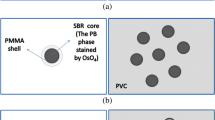

Methyl methacrylate-co-styrene-co-glycidyl methacrylate grafted polybutadiene (PB-g-MSG) and styrene-co-glycidyl methacrylate grafted polybutadiene (PB-g-SG) core-shell particles were prepared to toughen poly (butylene terephthalate) (PBT) and polycarbonate (PC) blends. The compatibilization reaction between the epoxy groups of glycidyl methacrylate and the carboxyl groups of PBT induced the PB-g-SG particles dispersed in the PBT phase. On the other hand, the good miscibility between PMMA (the shell phase of PB-g-MSG) and PC induced the PB-g-MSG particles dispersed in the PC phase. The different phase morphology led to different toughening behavior. The PBT/PC/PB-g-MSG blends with the PC encapsulated morphology showed much lower brittle-ductile transition core-shell particles content (10-15 wt% or 15-20 wt%) compared with the PBT/PC/PB-g-SG blends (20-25 wt%). The difference between the toughening efficiency of the core-shell particles was due to the change of deformation mechanisms. In PBT/PC/PB-g-MSG blends, the cavitation of PB rubber phase led to the occurrence of shear yielding of the matrix. While in the PBT/PC/PB-g-SG blends, the debonding between PBT and PC interface induced the shear yielding of the matrix. The variation of the core-shell particles dispersed phase morphology also affected the crystallization properties and DMA results of the PBT/PC blends. Modification of the phase morphology provided an useful strategy to prepare PBT/PC blends with higher toughening efficiency.

Similar content being viewed by others

References

He JX, Guo Y, Sun SL, Zhang HX (2015) J Polym Eng 3:247–256

Jose MRCAS, James T (2006) J Mater Chem 16:237–245

Kooshki RM, Ghasemi I, Karrabi M, Azizi H (2013) J Vinyl Addit Techn 19:203–212

Sonnier R, Viretto A, Taguet A, Lopez-Cuesta JM (2012) J Appl Polym Sci 125:3148–3158

Lei CH, Chen DH (2008) J Appl Polym Sci 109:1099–1104

DePolo WS, Baird DG (2009) Polym Compos 30:188–199

Kalkar AK, Siesler HW, Pfeifer F, Wadekar SA (2003) Polymer 44:7251–7264

Zaki MF, Elmaghraby EK, Elbasaty AB (2016) J Adhes Sci Technol 30:443–457

Bai HY, Zhang Y, Zhang YX, Zhang XF, Zhou W (2005) Polym Test 24:235–240

Bai HY, Zhang Y, Zhang YX, Zhang XF, Zhou W (2006) J Appl Polym Sci 101:54–62

Kalhoro MS, Gabrys BJ, Zajac W, King SM, Peiffer (2001) Polymer 42:1679–1690

Wen TT, Guo Y, Song SX, Sun SL, Zhang HX (2015) J Polym Res 22:222

Guo Y, He JX, Zhang XN, Sun SL, Zhang HX (2015) J Macromol Sci B 54:823835

Guo Y, Sun SL, Zhang HX (2014) RSC Adv 4:58880–58887

Lin GP, Lin L, Wang XL, Chen L, Wang YZ (2015) Ind Eng Chem Res 54:1282–1291

Sun SL, Zhang FF, Fu Y, Zhou C, Zhang HX (2013) J Macromol Sci B 52:861–872

Kuram E, Ozcelik B, Yilmaz F, Timur G, Sahin ZM (2014) Polym Compos 35:2074–2084

Kuram E, Timur G, Ozcelik B, Yilmaz F (2014) Mater Manuf Process 29:1260–1268

Zhang FF, Sun SL, Liu XY, Zhang LX, Zhang HX (2009) E-polymers 77:1–11

Wu JS, Wang K, Yu DM (2003) J Mater Sci 38:183–191

Wu JS, Mai YW, Yee AF (2000) J Mater Sci 35:307–315

Tseng WTW, Lee JS (2000) J Appl Polym Sci 76:1280–1284

Brady AJ, Keskkula H, Paul DR (1994) Polymer 35:3665–3672

Okamoto M, Shinoda Y, Kojima T, Inoue T (1994) Polymer 35:4868–4873

Memon AN (1994) J Appl Polym Sci 54:1059–1072

Hale W, Keskkula H, Paul DR (1999) Polymer 40:365–377

Oyamaa HT, Kitagawab T, Ougizawab T, Inouec T, Weberd M (2004) Polymer 45:10331043

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (51273025, 51272026, and 50803007) and Jilin Provincial Science & Technology Department (20140101104JC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, B., Guo, Y., Song, S. et al. Effect of core-shell particles dispersed morphology on the toughening behavior of PBT/PC blends. J Polym Res 23, 210 (2016). https://doi.org/10.1007/s10965-016-1106-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-016-1106-2