Abstract

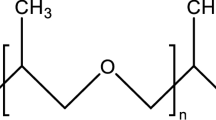

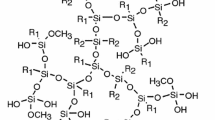

In this research, a series of epoxy-silicone copolymers were prepared from methyl phenyl silicone intermediates (PMPS) with a bisphenol A type epoxy resin (E-51) by condensation with dilaurate dibutyltin acting as catalyst. The chemical structure of the siloxane-bridged epoxy resin was characterized by Fourier transform infrared spectroscopy (FTIR), 1H-NMR and an epoxy equivalent weight (EEW) test. The modified epoxy resins showed better elongation at break and izod notched impact strength than neat resin. TGA results revealed that the residue at 600 °C of the modified epoxy resin increased with the increase of siloxane content. DMA tests displayed that the addition of silicone effectively enhanced the damping properties. Morphology studies indicated that the increase in izod notched impact strength is due to the suitable diameter of silicone phases because of the silicone toughening effect.

Similar content being viewed by others

References

Pan G, Du Z, Zhang C, Li C, Yang X, Li H (2007) Polymer 48:3686

Francis B, Thomas S, Sadhana R, Thuaud N, Ramaswamy R, Jose S, Rao VL (2007) J Polym Sci B Polym Phys 45:2481

Rostamiyan Y, Fereidoon AB, Hamed Mashhadzadeh A, Khalili MA (2013) J Polym Res 20:1

Tripathi G, Srivastava D (2008) Mater Sci Eng, A - Struct 496:483

Chen SB, Wang QH, Wang TM (2011) Polym Test 7:726

Roy PK, Ullas AV, Chaudhary S, Mangla V, Sharma P, Kumar D, Rajagopal C (2013) Iran Polym J 22:709

Asif A, Rao VL, Ninan KN (2011) Polym Adv Technol 22:437

Liu PG, Song JX, He LH, Liang XQ, Ding HY, Li QF (2008) Eur Polym J 44:940

Alagar M, Kumar AA, Prabu AA, Rajendran A (2004) Int J Polym Mater 53:45

Prabu AA, Alagar M (2005) J Macromol Sci, Part A: Pure Appl Chem 42:175

Huang W (2001) Polymer 42:1763

Wu SY (2002) J Appl Polym Sci 84:2352

Shon M, Kwon H (2009) Corros Sci 51:650

Jang M, Crivello JV (2003) J Polym Sci A Polym Chem 41:3056

Shih WC, Ma CCM, Yang JC, Chen HD (1999) J Appl Polym Sci 73:2739

Ku C-K, Lee Y-D (2007) Polymer 48:3

Lin ST, Huang SK (1996) J Polym Sci A Polym Chem 34:1907

Sharif A, Gupta AP, Eram S, Manawwer A, Pandey SK (2005) Prog Org Coat 54:248

Park SJ, Jin FL, Lee JR (2004) Macromol Chem Phys 205:2048

Loera AG, Cara F, Dumon M, Pascault JP (2002) Macromolecules 35:6291

Wang WJ, Perng LH, Hsiue GH, Chang FC (2000) Polymer 41:6113

Woo YJ, Jin LY, Bok LS (2014) Cryogenics 61:63

Deng L, Shen M, Yu J, Wu K, Ha C (2012) Ind Eng Chem Res 51:8178

Ananda Kumar S (2006) Eur Polym J 42:2419

Sultan JN, McGarry FJ (1973) Polym Eng Sci 13:29

Wu S (1985) Polymer 26:1855

Lu TL, Liang GZ, Peng YL, Chen T (2007) J Appl Polym Sci 106:411

Zhang C, Madbouly SA, Kessler MR (2015) ACS Appl Mater Interfaces 7:1226

Zhang C, Li Y, Chen R, Kessler MR (2014) ACS Sustainable Chem Eng 2:2465

Zhang C, Wu H, Kessler MR (2015) Polymer 69:52

Acknowledgments

The authors would like to thank the National Natural Science Foundation of China (51273118), the Science & Technology Pillar Program of Sichuan (2013FZ0006) and the Fundamental Research Funds for the Central Universities of China (2015SCU11008) for financial support, and the Analytical and Testing Center of Sichuan University for providing SEM measurements.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Heng, Z., Zeng, Z., Chen, Y. et al. Silicone modified epoxy resins with good toughness, damping properties and high thermal residual weight. J Polym Res 22, 203 (2015). https://doi.org/10.1007/s10965-015-0852-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-015-0852-x