Abstract

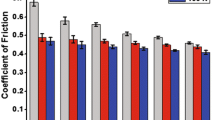

The nanocomposite films were synthesized based on the thermally stable benzoxazole-containing aromatic polyimide. The multi-walled carbon nanotubes in the concentrations from 0.25 to 1.0 wt.% were introduced in the matrix polymer as a nanofiller. Two types of nanotubes were used: the pristine nanotubes and those containing COOH-groups attached to the nanotubes’ surface. The impacts of the nanoparticles on the mechanical properties of the films in both single extension and creep conditions, and on the tribological properties of the material in the polymer/steel friction couple were tested. The positive actions of the COOH-containing nanotubes on both the mechanical properties and the tribological behavior of the studied materials were evidenced. These effects can be caused by the formation of the tightly packed nanocomposite structure in which the H-bonds are formed between CO- groups of the imide cycles of the polymer chains and COOH-groups of the nanotubes. The COOH-pretreatment hinders the aggregation processes of the nanotubes if their concentration in the composite films is less than ~1 wt. %.

Similar content being viewed by others

References

Hussain F (2006) J Compos Mater 40:1511–1575

Kasgöz H, Durmus A (2008) Polym Adv Technol 19:838–845

Bessonov MI, Koton MM, Kudryavtsev VV, Laius LA (1987) Polyimides—thermally stable polymers. Plenum Publishing Corp, New York

Garboczi EJ, Snyder KA, Douglas JF, Thorpe MF (1995) Phys Rev E 52:819–828

Iijima S (1991) Nature 354:56–58

Fang C, Zhao J, Jia J, Zhang Z, Zhang X, Li Q (2010) Appl Phys Lett 97:181906

Zhu BK, Xie S-H, Xu Z-K, Xu Y-Y (2006) Compos Sci Technol 66:548–554

So H, Cho J, Sahoo N (2007) Eur Polym J 43:3750–3756

Thuau D, Koutsos V, Cheung R (2009) J Vacuum Sci & Technol B: Microelectron and Nanometer Struct 27:3139–3144

Lebron-Colon M, Meador MA, Gaier JR, Sola F, Scheiman DA, McCorkle LS (2010) ACS Appl Mater Interfaces 2:669–676

Zhang B, Bershtein VA, Sukhanova TE, Zang W, Li Y, Chen C, Egorova LM, Gofman IV, Gubanova GN, Volkov AY, Vylegzhanina ME, Yakushev PN (2012) J Macromol Sci Phys 51:1794–1814

Kim SW, Kim T, Kim YS, Choi HS, Lim HJ, Yang SJ, Park CR (2012) Carbon 50:3–33

Assali M, Leal MP, Fernández I, Romero-Gomez P, Baati R, Khiar N (2010) Nano Res 3:764–778

Yang Z, Chen X, Chen C, Li W, Zhang H, Xu L, Yi B (2007) Polym Compos 28:36–41

Hatui G, Das CK (2013) J Polym Res 20:77

Gofman IV, Svetlichnyi VM, Yudin VE, Dobrodumov AV, Didenko AL, Abalov IV, Korytkova EN, Egorov AI, Gusarov VV (2007) Russ J Gen Chem 77:1158–1166

Delozier DM, Orwoll RA, Cahoon JF, Johnston NJ, Smith JG Jr, Connell JW (2002) Polymer 43:813–822

Gofman IV, Abalov IV, Tiranov VG, Yudin VE (2013) Polym Sci A 55:313–319

Myshkin NK, Kim CK, Petrokovets MI (1997) Introduction to tribology. CMG Publishers, Seoul

Hertz H (1882) Mathematik 92:156–171

Acknowledgments

The financial support provided by Russian Foundation for Basic Research (project No. 13- 03–00547) is acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Iosif Gofman and Baode Zhang contributed equally.

Rights and permissions

About this article

Cite this article

Gofman, I., Zhang, B., Zang, W. et al. Specific features of creep and tribological behavior of polyimide-carbon nanotubes nanocomposite films: effect of the nanotubes functionalization. J Polym Res 20, 258 (2013). https://doi.org/10.1007/s10965-013-0258-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-013-0258-6