Abstract

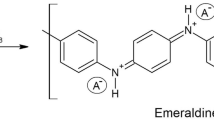

This paper describes the application of Taguchi experimental design to study the simultaneous effects of the dopant, the coagulant, and multiwalled carbon nanotubes (MWCNTs) used as reinforcing filler on the properties (tensile strength and electrical conductivity) of polyaniline (PANI) nanocomposite fibers produced via a wet spinning process. The MWCNT content was found to be the most significant factor, accounting for 72.8 % of the total contribution of the three selected parameters to the tensile strength. The dopant contributed 17.6 %, while the coagulant had a negligible effect and was therefore pooled. MWCNT content provided the maximum contribution of 98 % to the electrical conductivity, whereas the dopant and the coagulant had negligible effects, with contributions of 0.021 % and 0.247 %, respectively. A scanning electron microscope (SEM) and a tapping-mode atomic force microscope (AFM) were employed to study the morphology of the fibers. The electrochemical and pseudocapacitive properties of the fibers were investigated using cyclic voltammetry (CV). The PANI-AMPSA-MWCNT presented a specific capacitance value of 12.8 F cm−2. The thermal characteristics of the nanocomposite fibers were studied using thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). Elemental analysis of the fibers showed a high degree of doping: about 47–55 %.

Similar content being viewed by others

References

Bowman D, Mattes BR (2005) Conductive fibre prepared from ultra-high molecular weight polyaniline for smart fabric and interactive textile applications. Synth Met 154:29–32

Chiu CW, Lin CA, Hong PD (2011) Melt-spinning and thermal stability behavior of TiO2 nanoparticle/polypropylene nanocomposite fibers. J Polym Res 18:367–372

Arbab S, Noorpanah P, Mohammadi N, Zeinolebadi A (2011) Exploring the effects of non-solvent concentration, jet-stretching and hot-drawing on microstructure formation of poly(acrylonitrile) fibers during wet-spinning. J Polym Res 18:1343–1351

Skothem TA, Elsenbaumer RL, Reynolds JR (1998) Handbook of conducting polymers. Marcel Dekker, New York

Soroudi A, Skrifvars M (2010) Melt blending of carbon nanotubes/polyaniline/polypropylene compounds and their melt spinning to conductive fibres. Synth Met 160:1143–1147

Notin L, Viton C, Lucas JM, Domard A (2006) Pseudo-dry-spinning of chitosan. Acta Biomater 2:297–311

Jianming J, Wei P, Shenglin Y, Guang L (2005) Electrically conductive PANI-DBSA/Co-PAN composite fibers prepared by wet spinning. Synth Met 149:181–186

Mattes BR, Wang HL, Yang D, Zhua YT, Blumenthala WR, Hundleya MF (1997) Formation of conductive polyaniline fibers derived from highly concentrated emeraldine base solutions. Synth Met 84:45–49

Zhou J, Tzamalis G, Zaidi NA, Comfort NP, Monkman AP (2001) Effect of thermal aging on electrical conductivity of the 2-acrylamido-2-methyl-1-propanesulfonic acid-doped polyaniline fiber. J Appl Polym Sci 79:2503–2508

Mottaghitalab V, Xi B, Spinks GM, Wallace GG (2006) Polyaniline fibres containing single walled carbon nanotubes: enhanced performance artificial muscles. Synth Met 156:796–803

Mottaghitalab V, Spinks GM, Wallace GG (2006) The development and characterisation of polyaniline—single walled carbon nanotube composite fibres using 2-acrylamido-2 methyl-1-propane sulfonic acid (AMPSA) through one step wet spinning process. Polymer 47:4996–5002

Wang YZ, Joo J, Hsu CH, Epstein AJ (1995) Charge transport of camphor sulfonic acid-doped polyaniline and poly(o-toluidine) fibers: role of processing. Synth Met 68:207–211

Pomfret SJ, Adams PN, Comfort NP, Monkman AP (2000) Electrical and mechanical properties of polyaniline fibres produced by a one-step wet spinning process. Polymer 41:2265–2269

Pomfret SJ, Adams PN, Comfort NP, Monkman AP (1998) Inherently electrically conductive fibers wet spun from a sulfonic acid–doped polyaniline solution. Adv Mater 10:1351–1353

Liu Y, Li J, Pan ZJ (2011) Effect of spinning conditions on the mechanical properties of PA6/MWNTs nanofiber filaments. J Polym Res 18:2055–2060

Ross PJ (1996) Taguchi techniques for quality engineering. McGraw-Hill, New York

Stejskal J, Gilbert RG (2002) Polyaniline: preparation of a conducting polymer. Pure Appl Chem 74:857–867

Yang D, Adams PN, Mattes BR (2001) Intrinsic viscosity measurement of dilute emeraldine base solutions for estimating the weight average molecular weight of polyaniline. Synth Met 119:301–302

Mirmohseni A, Zavareh S (2010) Preparation and characterization of an epoxy nanocomposite toughened by a combination of thermoplastic, layered and particulate nano-filler. Mater Design 31:2699–2706

Sinha S, Bhadra S, Khastgir D (2009) Effect of dopant type on the properties of polyaniline. J Appl Polym Sci 112:3135–3140

Chung SF, Wen TC, Gopalan A (2005) Influence of dopant size on the junction properties of polyaniline. Mater Sci Eng B 116:125–130

Yoon SB, Yoon EH, Jim KB (2011) Electrochemical properties of leucoemeraldine, emeraldine, and pernigraniline forms of polyaniline/multi-Wall carbon nanotube nanocomposites for supercapacitor applications. J Power Sources 196:10791–10797

Zhou J, Tzamalis G, Zaidi NA, Comfort NP, Monkman AP (2001) Electrically conductive PAni multifilaments spun by a wet-spinning process. J Mater Sci 36:3089–3095

Acknowledgement

This paper was published as part of a research project supported by the University of Tabriz Research Affairs Office. The authors are grateful to the University of Tabriz for financial supports. They are also grateful to Mahar Fan Abzar Co. for the AFM images.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mirmohseni, A., Dorraji, M.S.S. Effects of dopant, coagulant, and reinforcing nanofiller on mechanical and electrical properties of wet-spun polyaniline nanocomposite fibers. J Polym Res 19, 9852 (2012). https://doi.org/10.1007/s10965-012-9852-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-012-9852-2