Abstract

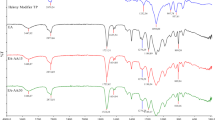

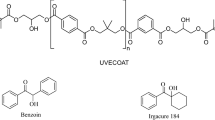

The bisphenol A epoxy acrylate resin containing a small amount of organically modified alpha-zirconium phosphate (α-ZrP) was cured within seconds upon UV irradiation at ambient temperature. The UV–curing behavior was investigated by fourier transformedinfrared spectroscopy (FTIR). The microstructures were characterized by X-ray diffraction (XRD) and transmission electron microscopy (TEM). The transparency and the combustion were examined by the UV–vis transmission spectra and Microscale Combustion Calorimeter (MCC), respectively. The ultraviolet–visible spectra of the cured films showed no obvious absorbance over a range of 400–800 nm, which revealed that the cured films were transparent. The results of MCC revealed that heat release rate (HRR) of the films decreased with the contents of organic α-ZrP (OZrP). Thermal behavior of the cured films was studied by thermogravimetric analysis (TGA), which indicated that with increasing the contents of OZrP, the char yields of UV-cured films were enhanced. Viscoelastic property of photocured nanocomposites was evaluated by dynamic-mechanical analysis. The effects of OZrP on the properties of UV curable films were critically evaluated in this paper.

Similar content being viewed by others

References

Ajayan PM, Schadler LS, Braun PV (2003) Nanocomposite science and technology. Wiley, New York

Sumita M, Tsukurmo T, Miyasaka K, Ishikawa K (1983) J Mater Sci 18:1758

Koleske JV (2002) Radiation curing of coatings. ASTM International, West Conshohocken, PA

Decker K, Eckhard S (1998) Polym Int 45:110

Jackson P (2002) Paint Resin Times 1:26

Fouassier JP (1995) Hanser Publishers, Munich

Tey JN, Soutar AM, Mhaisalkar SG, Yu H, Hew KM (2006) Thin Solid Films 504:384

Uhl FM, Davuluri SP, Wong SC, Webster DC (2004) Polymer 45:6175

Zahouily K, Decker C, Benfarhi S, Baron J. (2002) Proc RadTech North Am 309

Decker C (2003) Int Symp Polym Nanocompos Montreal 37

Decker C, Zahouily K, Keller L, Benfarhi S, Bendaikha T, Baron J (2002) J Mater Sci 37:4831

Bauer F, Flyunt R, Czihal K, Ernst H, Naumov S, Buchmeiser MR (2007) Nucl Instrum Methods, B 265:87

Grand AF, Wilkie CA (2000) Fire retardancy of polymeric materials. Marcel Dekker, New York

Lyons AM, Pearce EM, Mujsce AM (1990) J Polym Sci A: Polym Chem 28:245

Wilkie CA, Leone JT, Mittleman ML (1991) J Appl Polym Sci 42:1133

Beer RS, Wilkie CA, Mittleman ML (1992) J Appl Polym Sci 46:1095

Taniguchi M, Yamagishi A, Iwamoto T (1990) J Phys Chem 94:2534

Christensen AN, Andersen EK, Anderen IGK (1990) Acta Chem Scand 44:865

Zhang R, Hu Y, Song L, Zhu YR, Fan WC, Chen ZY (2001) Chinese J Nonferr Metals 11:895

Berchtold KA, Lu BH, Lovell L, Nie J, Bowman CN (2001) Macromolecules 34:5103

Wei H, Lu Y, Shi W, Yuan H, Chen Y (2001) J Appl Polym Sci 80:51

US Patent 6464391

Standard test method for heat and visible smoke release rates for materials and products, ASTM E 906. (1998) American Society for testing and materials, West Conshohocken, PA

Hergenrother PM, Thompson CM et al (2005) Polymer 46:5012

Zanetti M, Kashiwagi T, Falqui L, Camino U (2002) Chem Mater 14:881

Xie W, Gao ZM, Pan WP (2001) Chem Mater 13:2979

Sangermano M, Lak N, Malucelli G, Samakande A, Sanderson RD (2008) Prog Org Coat 61:89

Acknowledgements

The work was supported by the Program for Specialized Research Fund for the Doctoral Program of Higher Education (200803580008), the Program for Science and Technology of SuZhou (SG-0841), the Opening Project of State Key Laboratory of Environmental Adaptability for Industrial Product and the Program for the graduate innovation fund in University of Science and Technology of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xing, W., Song, L., Lv, X. et al. Preparation, combustion and thermal behaviors of UV-cured coatings containing organically modified α-ZrP. J Polym Res 18, 179–185 (2011). https://doi.org/10.1007/s10965-010-9405-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9405-5