Abstract

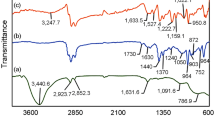

Styrene butadiene rubber (SBR) as matrix was reinforced separately with 9, 15 and 21 nm sizes of CaCO3, which were synthesized by matrix mediated growth technique. The mixing and compounding was done on two-roll mill and sheets were prepared in compression molding machine. The effect of nature and loading of nano CaCO3 on these rubber nanocomposites was investigated thoroughly by different characterizations such as DSC, TGA, XRD, and mechanical properties. An appreciable increase in glass transition temperature has been observed from DSC study. 9 nm sizes of CaCO3/SBR composites show more increment in Tg as compared to pristine SBR as well as different sizes of CaCO3 filled SBR. This increment in Tg is due to restricted mobility of nano CaCO3 filled SBR nanocomposites. XRD study of nanocomposites showed that nano CaCO3 dispersed uniformly throughout the matrix because of the small peak at lower 2θ. This uniform dispersion of nano CaCO3 contributes towards the higher mechanical properties of rubber composites. From TGA study, it was observed that as the size of CaCO3 reduces the thermal stability increases as compared to pristine SBR. The other results of these rubber nanocomposites were compared with commercial CaCO3 filled SBR.

Similar content being viewed by others

References

Giannelis EP (1996) Adv Mater 8:29

Chen T, Tien Y, Wei K (2000) Polymer 42:1345

Usuki A, Tukigase A, Kato M (2002) Polymer 43:2185

Fu X, Qutubuddin S (2001) Polymer 42:807

Zhang W, Chen D, Zhao Q, Fang Y (2003) Polymer 44:7953

Chang J, An Y (2002) J Polym Sci, Part B, Polym Phys 40:670

Chang J, An Y, Sur G (2003) J Polym Sci, Part B, Polym Phys 41:94

Liu Y, Wu C, Chiu Y, Ho W (2003) J Polym Sci, Part A, Polym Chem 41:2354

Mishra S, Sonawane SH, Singh RP, Bendale A, Patil K (2004) J Appl Polym Sci 94:116

Mishra S, Sonawane SH, Singh RP (2005) J Polym Sci, Part B: Polym Phys 43(1):107

Lan T, Kaviratna PD, Pinnavaia TJ (1995) Chem Mater 7:2144

Yoon JT, Jo WH, Lee MS, Ko MB (2001) Polymer 42:329

Kader MA, Nah C (2004) Polymer 45:2237

Arroyo M, Lopez-Manchado MA, Herrero B (2003) Polymer 44:2447

Brown MJ, Curliss D, Vaia RA (2000) Chem Mater 12:3376

Tjong SC, Meng YZ, Hay AS (2002) Chem Mater 14:44 494

Fornes TD, Hunter DL, Paul DR (2004) Macromolecules 37:1793

Choi YS, Ham HT, Chung IJ (2004) Chem Mater 16:2522 496

Zhang H, Wang Y, Wu Y, Zhang L, Yang J (2005) J Appl Polym Sci 97:844

Chan CM, Wu JS, Li JX, Cheung YK (2002) Polymer 43:2981–2992

Gopinath CS, Hedge SG, Ramaswamy AV, Mahapatra S (2002) Mater Res Bull 37:1323

Mishra S, Shimpi NG (2005) J Sci Ind Res 41:744

Mishra S, Shimpi NG (2005) J Appl Polym Sci 98:2563

Pathak A, Panda AB, Tarafdar A, Pramanik P (2003) J Indian Chem Soc 80:289 510

Mishra S, Sonawane SH, Badgujar N, Gurav K, Patil D (2005) J Appl Polym Sci 96:6 512

Manchando MA, Herrero B, Arroyo M (2003) Polym Int 52:1070

Usuki A, Koiwai A, Kojima Y, Kawasumi M, Okada A, Fukushima Y, Kurachi T, Kamigaito O (1993) J Mater Res 8(5):1179

Kim JT, Oh T-S, Lee D-H (2003) Polym Int 52:1058

Chang Y-W, Yang Y, Ryu S, Nah C (2002) Polym Int 51:319

Flory PJ (1953) In: Principles of polymer chemistry. Cornell University. Ithaca, New York 519

Chang YW, Yang Y, Ryu S, Nah C (2002) Polym Int 51:319

Chen G, Lin S, Chen S, Qi Z (2001) Macromol Chem Phys 202:1189

Fujiwara S, Sakamato T (1976) Kokai Patent SHO 51, 109998

Gilman JW (1999) App Clay Sci 15:31

Acknowledgment

Authors are thankful to Council of Scientific and Industrial Research, New Delhi (CSIR) for financial assistance to carry out this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Partly this research paper has been presented in International conference on ‘RubberChem 2006, Dec 5–6, 2006, Munich, Germany.

Rights and permissions

About this article

Cite this article

Mishra, S., Shimpi, N.G. & Patil, U.D. Effect of Nano CaCO3 on thermal properties of Styrene Butadiene Rubber (SBR). J Polym Res 14, 449–459 (2007). https://doi.org/10.1007/s10965-007-9127-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-007-9127-5