Abstract

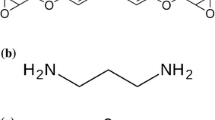

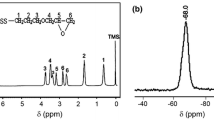

The physical aging process of 4-4′-diaminodiphenylsulfone (DDS) cured diglycidyl ether bisphenol-A (DGEBA) blended with various molecular weights of poly(ether sulfone) (PES; Mn = 28,600, 10,600, and 6,137) was studied by DSC. For DGEBA/DDS system blended with a low MW PES-3 (Mn = 6,137), no phase separation of the polymer blend and only one enthalpic relaxation process due to physical aging was observed. Since the high MW PES-1 (Mn = 28,600) had a Tg close to that of fully cured DGEBA/DDS, the fully cured DGEBA/DDS/PES-1 blend had a broader glass transition than a neat DGEBA/DDS system. However, the DSC results showed two enthalpic relaxation processes due to the physical aging of PES-rich and cured epoxy-rich phases as the material was aged at 155 °C (30 °C below Tg). Since the Tgs of PES-1-rich and epoxy-rich phases overlapped with each other, the enthalpic relaxation processes corresponding to each phase coupled to each other in the earlier stage of physical aging. The medium MW PES-2 (Mn = 10,600) has a much lower Tg than that of fully cured DGEBA/DDS, two well separated Tgs were observed for the cured DGEBA/DDS/PES-2 blend, indicating the cured epoxy was immiscible with PES. Aging the polymer blend at 155 °C (24 °C below Tg1 of the PES-2-rich phase and 53 °C below Tg2 of the epoxy-rich phase) produced two well separated relaxation processes due to PES-2-rich and epoxy-rich phases. The experimental results suggested that aging the polymer blend at a suitable temperature would improve the phase separation between PES-1-rich and epoxy-rich phases.

Similar content being viewed by others

References

L. C. E. Struik, Physical aging in amorphous polymers and other materials, Amsterdam, 1978.

A. S. Marshall and S. E. B. Petrie, J. Appl. Phys., 46, 4223 (1975).

A. J. Kovacs, J. J. Aklonis, J. M. Hutchinson and A. R. Ramos, J. Polym. Sci., Polym. Phys. Ed., 17, 1097 (1979).

A. Agrawal, J. Polym. Sci., Polym. Phys., Ed., 27, 1449 (1989).

A. K. Doolittle, J. Appl. Phys., 39, 3369 (1963).

H. S. Chen and T. T. Wang, J. Appl. Phys., 52, 5898 (1981).

A. J. Kovacs, Adv. Polym. Sci., 3, 394 (1963).

Z. H. Ophir, J. A. Emerson and G. L. Wikes, J. Appl. Phys., 49, 5032 (1978).

A. Buchman and D. Katz, Polym. Eng. Sci., 19, 923 (1979).

R. J. Morgan, J. Appl. Polym. Sci., 23, 2711 (1979).

J. Kaiser, Makromol. Chem., 180, 573 (1979).

T. D. Chang and J. O. Brittan, Polym. Eng. Sci., 22, 1221 (1982).

E. S. Kong, Adv. Polym. Sci., 80, 125 (1986).

E. S. W. Kong, G. L. Wikes, J. E. McGrath, A. K. Banthia, Y. Mohajer and M. R. Tant, Polym. Eng. Sci., 21, 943 (1981).

Y. G. Lin, H. Sautereau and J. P. Pascault, J. Appl. Polym. Sci., 32, 4595 (1986).

I. C. Choy and D. J. Plazek, J. Polym. Sci., Polym. Phys. Ed., 24, 1303 (1986).

D. J. Plazek and I. C. Choy, J. Polym. Sci., Polym. Phys. Ed., 27, 307 (1989).

D. J. Plazek and Z. N. Frund, J. Polym. Sci., Polym. Phys. Ed., 28, 431 (1990).

A. Lee and G. B. McKenna, Polymer, 29, 1812 (1988).

A. Lee and G. B. McKenna, Polymer, 31, 423 (1990).

C. G’Sell and G. B. McKenna, Polymer, 33, 2103 (1992).

S. Montserrat, J. Appl. Polym. Sci., 44, 545 (1992).

S. Montserrat, J. Polym. Sci., Polym. Phys. Ed., 32, 509 (1994).

J. M. Hutchinson, D. McCarthy, S. Montserrat and P. Cortes, J. Polym. Sci., Polym. Phys. Ed., 34, 229 (1996).

P. Cortes, S. Montserrat and J. M. Hutchinson, J. Appl. Polym. Sci., 63, 17 (1997).

A. Lee and G. B. McKenna, J. Polym. Sci., Polym. Phys. Ed., 35, 1167 (1997).

J. S. Shen, Z. Shao and S. Li, Polymer, 36, 3479 (1995).

C. D. Breach, M. J. Folkes and J. M. Barton, Polymer, 33, 3080 (1992).

J. M. G. Cowie and R. Ferguson, Macromolecules, 22, 2312 (1989).

J. L. Hedrick, PhD Thesis, Dept. of Chem., Virginia Polytech Institute, USA (1986).

P. K. Monhanty, J. L. Hedrick, K. Gobetz, B. C. Johnson, I. Yilgor, R. Yang and J. E. McGrath, Polym. Prepr. (Am. Chem. Soc., Div. Polym. Chem.) 23, 284 (1982).

R. B. Prime, Thermal Analysis in Polymer Characterization, E. Turi, Ed., Heyden, Pa., 1981.

I. M. Hodge and A. R. Berens, Macromolecules, 15, 762 (1982).

J. L. Ribelles, R. D. Calleja, R. Ferguson and J. M. G. Cowie, Polymer, 28, 2262 (1987).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Leon Yu, T., Chen, Y.S. Physical aging of epoxy resin blended with poly(ether sulfone): Effect of poly(ether sulfone) molecular weight. J Polym Res 7, 257–266 (2000). https://doi.org/10.1007/s10965-006-0128-6

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10965-006-0128-6