Abstract

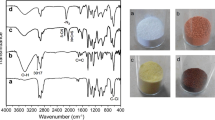

Block copolyetheresters with hard segments of poly(trimethylene 2,6-naphthalenedicarboxylate) and soft segments of poly(tetramethylene oxide) were prepared by melt polycondensation of dimethyl 2,6-naphthalenedicarboxylate, 1,3-propanediol and poly(tetramethylene ether)glycol (PTMEG) of molecular weights of 650, 1000 and 2000. The block copolyetheresters were characterized by FTIR, 1H NMR, DSC, X-ray diffraction, TSC (thermal stimulated current), DMA and TGA. It was found that the thermal transitions were dependent on the composition. As the charge molar ratio of PTMEG to dimethyl 2,6-naphthalenedicarboxylate, x, increased, the Tm and ΔHm of the polyester segments decreased, which has been also confirmed by the X-ray diffraction data. The polyether segments of the block copolyetheresters derived from PTMEG2000 could crystallize after cooling, but those of the block copolyetheresters derived from PTMEG1000 and PTMEG650 could not crystallize. The DSC, TSC and DMA results show consistent Tg data of the polyether segments. Based on the shift in Tg of the polyether segments, the amorphous parts of the polyether segments and the amorphous parts of the polyester segments were immiscible for the block copolyetheresters derived from PTMEG2000, but became partially miscible for the block copolyetheresters derived from PTMEG1000 and PTMEG650. The TGA results indicated that composition had little effect on thermal degradation under nitrogen.

Similar content being viewed by others

References

N. R. Legge, G. Holder and H. E. Schroeder, Eds., Thermoplastic Elastomers: A Comprehensive Review, Hanser Publishers, New York, 1987.

A. K. Bhowmick and H. L. Stephens (Eds.), Handbook of Elastomers: New Developments and Technology, Marcel Dekker, New York, 1988.

J. C. Shivers and W. Chester, U. S. Pat. 3,023,192 (1962).

W. K. Witsiepe, U. S. Pat. 3,651,014 (1972).

J. R. Wolfe, Jr., U. S. Pat. 3,775,374 (1973).

G. K. Hoeschele U. S. Pat. 3,801,547 (1974).

J. R. Wolfe, Jr., Multiphase Polymers, ACS Advances in Chemistry Series 176, S. L. Cooper and G. M. Estes, Eds., pp. 129–151, ACS, Washington D. C., 1979.

H. Schroeder and R. J. Cella, Encyclopedia of Polymer Science and Engineering, H. Mark, N. M. Bikales, C. G. Overberger, G. Menges and J. I. Kroschwits, Eds., 2nd Ed., Vol. 12, pp. 75–117, Wiley, New York, 1988.

R. W. Seymour, J. R. Overton and L. S. Corley, Macromolecules, 8, 331 (1975).

C. M. Boussias, R. H. Peters and R. H. Still, J. Appl. Polym. Sci., 25, 855 (1980).

L. L. Zhu and G. Wegner, Makromol. Chem., 182, 3625 (1981).

R. M. Briber and E. L. Thomas, Polymer, 26, 8 (1985).

J. L. Castles, M. A. Vallance, J. M. McKenna and S. L. Cooper, J. Polym. Sic., Polym. Phys., 23, 2119 (1985).

J. C. Stevenson and S. L. Cooper, J. Polym. Sic., Polym. Phys., 26, 953 (1988).

J. C. Stevenson and S. L. Cooper, Macromolecules, 21, 1309 (1988).

R. A. Phillips, J. M. McKenna and S. L. Cooper, J. Polym. Sic., Polym. Phys., 32, 791 (1994).

S. J. Chang, F. C. Chang and H. B. Tsai, Polm. Eng. Sci., 35, 190 (1994).

H. B. Tsai, C. Lee and N. S. Chang, Polym. J., 24, 157 (1992).

N. T. Hsiue, C. C. M. Ma and H. B. Tsai, J. Polym. Sic., Polym. Chem., 33, 1153 (1995).

H. B. Tsai, D. K. Lee, J. L. Liu, Y. S. Tsao, R. S. Tsai and J. W. You, Polym. Bull., 35, 743 (1995).

I. N. Duling and W. Chester, U. S. Pat. 3,436,376 (1969).

R. S. Tsai and Y. D. Lee, J. Appl. Polym. Sci., 66, 1411 (1997).

J. P. Ibar, Fundamentals of Thermal Stimulated Current and Relaxation Map Analysis, SLP Press, Newcaan, 1993.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tsai, RS., Lee, YD. Block copolyetheresters with poly(trimethylene 2,6-naphthalenedicarboxylate) segments: Effect of composition on thermal properties. J Polym Res 5, 77–84 (1998). https://doi.org/10.1007/s10965-006-0043-x

Issue Date:

DOI: https://doi.org/10.1007/s10965-006-0043-x