Abstract

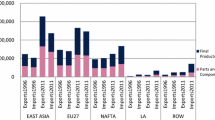

This paper examines supply chain value added in the US for producing assembly-centric products, which includes machinery, computers, electronics, and transportation equipment, and determines whether costs are disproportionally distributed. The implication being that reductions in resource consumption in some cost areas can disproportionally reduce total resource consumption. Efforts to develop and disseminate innovative solutions to improve efficiency can, therefore, be targeted to these high cost areas, resulting in larger efficiency improvements than might otherwise be achieved. An input–output model is used for this examination and is combined with labor data and data on assets. The top 20 industries, occupations, and industry occupation combinations contributing to production are identified. A sensitivity analysis is conducted on the model using Monte Carlo simulation. The results confirm that costs are disproportionally distributed, having a Gini coefficient of 0.75 for value added and for compensation it is 0.86. Wholesale trade, aircraft manufacturing, and the management of companies and enterprises were the industries with the largest contribution to assembly-centric manufacturing, even when including imports. Energy in the form of electricity and natural gas were discussed separately, but would rank 8th if compared to the industry rankings. In terms of occupation activities, team assemblers, general and operations managers, and sales representatives were the largest occupations. Public entities might use this model and results to identify efficiency improvement efforts that will have the largest impact on industry per dollar of expenditure.

Similar content being viewed by others

Notes

Calculated using Input–Output analysis of the BEA Benchmark data.

It is important to note that the capital purchases and the goods and services used up in production cannot be added together as it would be double counting some values.

The steel and aluminum industry often produce standard shapes rather than customized shapes tailored to specific products. This results in needing to cut away some portion of material, which ends up as scrap.

References

Albino, V., Izzo, C., & Kühtz, S. (2002). Input–output models for the analysis of local/global supply chains. International Journal of Production Economics, 78(2), 119–131.

Allwood, J. M. & Cullen, J. M. (2012). Sustainable materials with both eyes open. Cambridge Ltd. p. 185. http://www.withbotheyesopen.com/.

Australian Logistics Council. (2014). The economic significance of the australian logistics industry. http://austlogistics.com.au/wp-content/uploads/2014/07/Economic-Significance-of-the-Australian-Logistics-Indsutry-FINAL.pdf.

Bhatnagar, R., & Sohal, A. S. (2005). Supply chain competitiveness: Measuring the impact of location factors, uncertainty and manufacturing practices. Technovation, 25, 443–456.

Beynon, M. J., & Munday, M. (2007). An aggregated regional economic input–output analysis within a fuzzy environment. Spatial Economic Analysis, 2(3), 281–296.

Beynon, M. J., Munday, M., & Roberts, A. (2005). Ranking sectors using fuzzy output multipliers. Economic Systems Research, 17(3), 237–253.

Block, F. L., & Keller, M. R. (2016). State of innovation: the US government’s role in technology development. New York, NY: Taylor & Francis.

Bray, R. L., & Mendelson, H. (2012). Management science. Information transmission and the bullwhip effect: An empirical investigation (pp. 860–875). http://dx.doi.org/10.1287/mnsc.1110.1467.

Bureau of Economic Analysis. (2014). Input–output accounts data. http://www.bea.gov/industry/io_annual.htm.

Bureau of Transportation Statistics. (2015) Freight facts and figures 2015. Tables 3–11 (p. 41). https://www.rita.dot.gov/bts/sites/rita.dot.gov.bts/files/FFF_complete.pdf.

Butler, D. M., Atler, A., Worman, S. M., Geyer, L., & Magnuson, B. (2016). Identifying efficiencies in the supply chain for training ammunition. RAND Corporation. http://www.rand.org/pubs/research_reports/RR952.html.

Diaz, B., & Morillas, A. (2011). Incorporating uncertainty in the coefficients and multipliers of an IO table: a case study. Papers in Regional Science, 90(4), 845–861.

Economist. (2008). Delayering. http://www.economist.com/node/12677027.

Egilmez, G., Gumus, S., Kucukvar, M., & Tatari, O. (2016). A fuzzy data envelopment analysis framework for dealing with uncertainty impacts of input–output life cycle assessment models on eco-efficiency assessment. Journal of Cleaner Production, 129(15), 622–636. doi:10.1016/j.jclepro.2016.03.111.

Energy Information Administration. (2010). Manufacturing Energy Consumption Survey. http://www.eia.gov/consumption/manufacturing/.

European Commission. (2008). Eurostat manual of supply, use, and input–output tables. 2008 Edition. http://ec.europa.eu/eurostat/documents/3859598/5902113/KS-RA-07-013-EN.PDF/b0b3d71e-3930-4442-94be-70b36cea9b39?version=1.0.

European Science and Technology Observatory. (2006). Environmental impact of products: Analysis of the life cycle environmental impacts related to the final consumption of the EU-25. http://ec.europa.eu/environment/ipp/pdf/eipro_report.pdf.

Fenton, M. D. (2001). Iron and steel recycyling in the United States in 1998. Report 01-224. US Geological Survey: 3. https://pubs.usgs.gov/of/2001/of01-224/.

Harris, C. M. (1984). Issues in Sensitivity and Statistical Analysis of Large-Scale, Computer-Based Models, NBS GCR 84-466. Gaithersburg, MD: National Bureau of Standards.

Hopp, Wallace J., & Spearman, Mark L. (2008). Factory Physics (3rd ed., p. 674). Long Grove, IL: Waveland Press.

Horowitz, K. J., & Planting, M. A. (2006). Concepts and Methods of the US input–output accounts. Bureau of Economic Analysis. http://www.bea.gov/papers/pdf/IOmanual_092906.pdf.

Klein, M. W. (2002). Mathematical methods for economics (2nd ed., pp. 393–396). Boston, MA: Pearson Education Inc.

Lee, H. L., Padmanabhan, P., & Whang, S. (1997). The bullwhip effect in supply chains. Sloan Management Review, 38, 93–102.

Lee, Y. T., Riddick, F. H., & Hohansson, B. J. I. (2011). Core manufacturing simulation data—a manufacturing simulation integration standard: overview and case studies. International Journal of Computer Integrated Manufacturing, 24(8), 689–709.

Lu, W., & Rencheng, T. (2007). For multi-location supply chain management control: A theoretic model. 16th International conference on input–output techniques. https://www.iioa.org/conferences/16th/files/Papers/Wang-274.pdf.

Manufacturing Extension Partnership. (2017). Manufacturing successes in America. http://ws680.nist.gov/mepmeis/ManufacturingSuccesses.aspx.

McKay, M. C., Conover, W. H., & Beckman, R. J. (1979). A comparison of three methods for selecting values of input variables in the analysis of output from a computer code. Technometrics, 21, 239–245.

McKinsey Global Institute. (2010). How to compete and grow: A sector guide to policy. http://www.mckinsey.com/industries/public-sector/our-insights/how-to-compete-and-grow.

McKinsey & Company. (2012). Manufacturing the future: The next era of global growth and innovation. http://www.mckinsey.com/business-functions/operations/our-insights/the-future-of-manufacturing.

Miller, R. E., & Blair, P. D. (2009). Input–output analysis: Foundations and extensions (2nd ed.). New York, NY: Cambridge University Press.

Mohr, S., Somers, K., Swatz, S., & Vanthournout, H. (2012). Manufacturing resource productivity. http://www.mckinsey.com/business-functions/sustainability-and-resource-productivity/our-insights/manufacturing-resource-productivity.

National Institute of Standards and Technology. (2017). NIST general information. http://www.nist.gov/public_affairs/general_information.cfm.

National Science Foundation. (2004). On the origins of Google. https://www.nsf.gov/discoveries/disc_summ.jsp?cntn_id=100660.

Robert D. Niehaus, Inc. (2014). Reassessing the economic impacts of the International Standard for the Exchange of Product Model Data (STEP) on the US transportation equipment manufacturing industry. Contract SB1341-12-CN-0084.

Oracle. (2013). Crystal Ball, Crystal Ball 11.1.2.3 user manual. Denver, CO: Decisioneering, Inc.

Raina, R., & Thomas, M. (2012). Fuzzy vs. probabilistic techniques to address uncertainty for radial distribution load flow simulation. Energy and Power Engineering, 4, 99–105. doi:10.4236/epe.2012.42014.

RS Means. (2005). RS means mechanical cost data (28th ed., p. 558). Kingston, MA: RS Means.

Science Daily. (2011). Ride-sharing for road freight. https://www.sciencedaily.com/releases/2011/04/110406132022.htm.

Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (2008). Designing and managing the supply chain: Concepts, strategies, and case studies (3rd ed.). New York, NY: McGraw-Hill Irwin.

Tassey, G. (2010). Rationales and mechanisms for revitalizing US manufacturing R&D strategies. Journal of Technology Transfer, 35, 283–333.

Temurshoev, U. (2015). Uncertainty treatment in input–output analysis. http://loyolaandnews.es/loyolaecon/wp-content/uploads/2015/12/Uncertainty-treatment-in-Input–Output–analysis.pdf.

Thomas, D. S., & Kandaswamy, A. M. (2015). Tracking industry operations activity: A case study of US automotive manufacturing. NIST Special Publication 1601. doi: 10.6028/NIST.SP.1601.

Weil, D. N. (2005). Economic growth. Upper Saddle River: Pearson Education Inc.

Wessner, C. W., & Wolff A. W. (2012). Rising to the challenge: US innovation policy for the global economy. National Research Council (US) Committee on Comparative National Innovation Policies: Best Practice for the 21st Century. Washington (DC): National Academies Press (US). http://www.ncbi.nlm.nih.gov/books/NBK100307/

Author information

Authors and Affiliations

Corresponding author

Additional information

Disclaimer: Certain trade names and company products are mentioned in the text in order to adequately specify the technical procedures and equipment used. In no case does such identification imply recommendation or endorsement by the National Institute of Standards and Technology, nor does it imply that the products are necessarily the best available for the purpose.

Rights and permissions

About this article

Cite this article

Thomas, D., Kandaswamy, A. Identifying high resource consumption areas of assembly-centric manufacturing in the United States. J Technol Transf 44, 264–311 (2019). https://doi.org/10.1007/s10961-017-9577-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10961-017-9577-9