Abstract

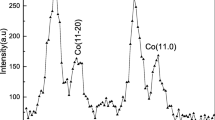

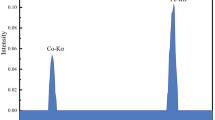

A series of thin layers of cobalt are deposited on GaAs semiconductor substrate, using thermal heating process, under a pressure of 10 −7mbar. The thickness ranges from 18 to 250 nm, values determined by X-ray reflectivity (XRR) technique, and monitored by Rigaku X-ray diffractometer. The hysteresis loops are performed by means of Physical Property Measurement System (PPMS) with Quantum Design Instrument. All the samples are polycrystalline and present a hexagonal close-packed (hcp) structure, some films being under stress. The hysteresis loops display magnetization curves for ferromagnetic samples with the easy axis in the plane of the film. Coercivity seems to depend closely on surface roughness and crystallite size. The lowest value of H c, equals to 13 Oe, is related to the smoothest film with a raw mean square (rms) value equal to 0.1 nm, and the smallest stress (0.33 %). Samples with larger crystallites size have larger coercive fields.

Similar content being viewed by others

References

Valev, J.P., Jaswal, S.S., Tsymbal, E.Y.: Phys. Rev. Lett. 95, 216601 (2005)

Yuasa, S., Katayama, T., Nagahama, T.: Phys. Rev. Lett. 87, 222508 (2005)

Sharma, A., Tripathi, S., Lakshmi, N., Sachdev, P., Shripathi, T.: Solid State Commun. 149, 1033–1038 (2009)

Islam, J., Yamamoto, Y., Hori, H.: J. Magn. Magn. Mater. 310, 2234–2236 (2007)

Croce, P.: Étude des surfaces, en particulier des rugosités par rayons X rasants. Acta Electron., (F) 24(247-253), 1981–1982

Parratt, L.G.: Phys. Rev. 95, 359 (1954)

Yazaka, M.: X-ray thin-film measurement techniques. Rigaku J. 26(2) (2010)

Sharma, A., Tripathi, S., Brajpuriy, R., Chaudhari, S.M.: Appl. Surf. Sci. 252, 8571–8575 (2006)

Eberhart, J.P.: Analyse Structurale et Chimiques des Matériaux, Bordas, Paris (1998)

Louër, D.: J. Phys. IV Fr 103 (2003)

Li, M., Zhao, Y.-P., Wang, G.-C.: J. Appl. Phys. 83, 6287 (1998)

Zhao, Y.-P., Gamache, R.M., Wang, G.-C., Lu, T.-M., Palasantzas, G., Hosson, J.Th.M.De.: J. Appl. Phys. 89, 1325 (2001)

Shukla, V., Mukherjee, C., Chari, R., Rai, S., Bindra, K.S., Banerjee, A.: J. Magn. Magn. Mater. 370, 100–105 (2014)

Prinz, G.A.: Phys. Rev. Lett. 54, 1051 (1985)

Bland, J.A.C., Bateson, R.D., Riedi, P.C., Graham, R.G., Lauter, H.J., Penfold, J., Shackleton, C.: J. Appl. Phys. 69, 4989 (1991)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tinouche, M., Kharmouche, A., Aktaş, B. et al. Magnetic and Structural Properties of Co Thin Films Evaporated on GaAs Substrate. J Supercond Nov Magn 28, 921–925 (2015). https://doi.org/10.1007/s10948-014-2863-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-014-2863-y