Abstract

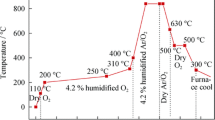

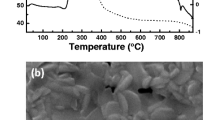

YBa2Cu3O7−x (YBCO) films were prepared on LaAlO3 single crystal substrate under various firing temperatures (750–800 °C) in the crystallization process by metalorganic deposition (MOD) method. The coating solution was made by mixing the fluorine-free precursor solution containing Y and Cu with Ba–fluorine precursor solution (Ba-TFA). The effect of firing temperature on the structure and superconducting properties of YBCO films was systematically investigated. The results indicated that YBCO-films were smooth, crack-free, exhibited good textures and retain high oxygen content according to the XRD and SEM images. Sample of YBCO-film fired at 780 °C showed highest superconducting properties including high critical transition temperature T c=89 K, sharp transition temperature ΔT c<1 K, and critical current density J c=2.8 MA cm−2, which are attributable to excellent in-plane textures and dense microstructures with good connectivity between the grains.

Similar content being viewed by others

References

Shiohara, Y., Yoshizumi, M., Izumi, T., et al.: Supercond. Sci. Technol. 21, 34002 (2008)

Tsukamoto, O., Enomoto, Y.: Physics C 392–396, 778 (2003)

Chen, M., Donzel, L., Lakner, M., et al.: J. Eur. Ceram. Soc. 24, 1815 (2004)

Gupta, A., Jagannathan, R., Cooper, E.I., et al.: Appl. Phys. Lett. 52, 2077 (1988)

Araki, T., Yuasa, T., Kurosaki, H., Yamada, Y., et al.: Supercond. Sci. Technol. 15, L1 (2002)

Tokunaga, Y., Honjo, T., Izumi, T., et al.: Cryogenics 44, 817 (2004)

Araki, T., Yamagiwa, K., Hirabayashi, I., et al.: Supercond. Sci. Technol. 14, L21 (2001)

Durrell, J.H., Rutter, N.A.: Supercond. Sci. Technol. 22, 013001 (2009)

Arendt, P.N., Foltyn, S.R.: Mater. Res. Soc. Bull. 29, 543 (2004)

Cai, Y.Q., Tang, C.Y., Sun, L.J., et al.: Cryst. Growth Des. 7, 1469 (2007)

Singh, R.K., Kumar, D.: Mater. Sci. Eng., R Rep. 22, 113 (1998)

Cai, Y.Q., Yao, X., Lai, Y.J.: J. Appl. Phys. 99, 113909 (2006)

Suenaga, M.: Physica C 378–381, 1045 (2002)

Kato, T., Sasaki, H., Iwai, H., et al.: Physica C 426–431, 1033 (2005)

Ramesh, R., Inam, A., Hwang, D.M., et al.: Appl. Phys. Lett. 58, 1557 (1991)

Yoshizumi, M., Seleznev, I., Cima, M.J.: Physics C 403, 191 (2004)

Demirel, A.I.: Supercond. Sci. Technol. 15, 923 (2002)

Shin, G.M., Ko, K.P., Song, K.J., et al.: Physica C 468, 1567 (2008)

McIntyre, P.C., Cima, M.J.: J. Mater. Res. 9, 2778 (1994)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, R., Li, T., Chen, Z. et al. Effect of Firing Temperature on the Structure and Superconducting Properties of YBa2Cu3O7−x Films. J Supercond Nov Magn 24, 1797–1801 (2011). https://doi.org/10.1007/s10948-011-1126-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-011-1126-4