Abstract

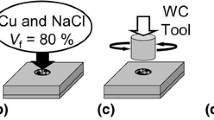

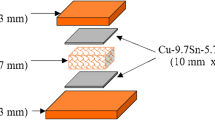

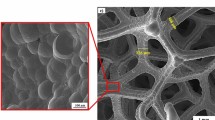

Open-cell metal foams suffer from severe deterioration in mechanical properties due to their enriched three-dimensional interconnected holes. In this paper, reinforcing copper pillar(s) or tube(s) are embedded into the foam matrix to form “composite” structure to enhance the open-cell copper foams. To do this, a simple positioning device is designed for preparation of the green porous copper aligned with directional through hole(s) based on a tapping method. Then the reinforcing pillar(s) or tube(s) are inserted into the hole(s) and sintered together. By this means, the mechanical properties of the copper foams are significantly improved. The energy absorption capacity of the composite foams has also been improved because of a higher and wider yield platform compared with the unreinforced copper foams.

Similar content being viewed by others

References

W. Li, H. Jia, C. Pu, X. Liu, J. Xie, Cell wall buckling mediated energy absorption in lotus-type porous copper. J. Mater. Sci. Technol. 96, 82–94 (2015)

M. Vesenjak, K. Hokamoto, M. Sakamoto, T. Nishi, L. Krstulović-Opara, Z. Ren, Mechanical and microstructural analysis of unidirectional porous (UniPore) copper. Mater. Des. 90, 867–880 (2016)

M.F. Ashby, R.F. MehlMedalist, The mechanical properties of cellular solids. Metall. Mater. Trans. A 14A, 1755–1769 (1983)

P. Lhuissier, Structural properties of solid foams. C. R. Phys. 15, 696–704 (2014)

C. Kılıçaslan, Numerical crushing analysis of aluminum foam-filled corrugated single- and double-circular tubes subjected to axial impact loading. Thin Wall Struct. 96, 82–94 (2015)

M.F. Ashby, T. Lu, Metal foams: a survey. Sci. China Ser. B 46, 521–532 (2003)

A.M. Parvanian, M. Panjepour, Mechanical behavior improvement of open-pore copper foams synthesized through space holder technique. Mater. Des. 49, 834–841 (2013)

L.P. Zhang, Y.Y. Zhao, Fabrication of high melting-point porous metals by lost carbonate sintering porous process via decomposition route. Proc. Inst. Mech. Eng. B 222, 267–271 (2008)

N. Bekoz, E. Oktay, Mechanical properties of low alloy steel foams: dependency on porosity and pore size. Mater. Sci. Eng. A 576, 82–90 (2013)

S.W. Kim, H.D. Jung, M.H. Kang, H.E. Kim, Y.H. Koh, Y. Estrin, Fabrication of porous titanium scaffold with controlled porous structure and net-shape using magnesium as spacer. Mater. Sci. Eng. C 33, 2808–2815 (2013)

A. Jinnapat, A.R. Kennedy, The manufacture of spherical salt beads and their use as dissolvable templates for the production of cellular solids via a powder metallurgy route. J. Alloys Compd. 499, 43–47 (2010)

B. Lee, T. Lee, Y. Lee, D.J. Lee, J. Jeong, J. Yuh, S.H. Oh, H.S. Kim, C.S. Lee, Space-holder effect on designing pore structure and determining mechanical properties in porous titanium. Mater. Des. 57, 712–718 (2014)

D.P. Mondal, M. Patel, S. Das, A.K. Jha, H. Jain, G. Gupta, S.B. Arya, Titanium foam with coaser cell size and wide range of porosity using different types of evaporative space holders through powder metallurgy route. Mater. Des. 63, 89–99 (2014)

D.C. Dunand, Processing of titanium foams. Adv. Eng. Mater. 6, 369–376 (2004)

J. Jia, A.R. Siddiq, A.R. Kennedy, Porous titanium manufactured by a novel powder tapping method using spherical salt bead space holders: characterisation and mechanical properties. J. Mech. Behav. Biomed. 48, 229–240 (2015)

M. Sabzevari, S.A. Sajjadi, A. Moloodi, Physical and mechanical properties of porous copper nanocomposite produced by powder metallurgy. Adv. Powder Technol. 27, 105–111 (2016)

M. Sharma, O.P. Modi, P. Kumar, Experimental modelling of copper foams processed through powder metallurgy route using a compressible space holder material. J. Porous Mater. 24, 1581–1593 (2017)

M.H. Shahzeydi, A.M. Parvanian, M. Panjepour, The distribution and mechanism of pore formation in copper foams fabricated by Lost Carbonate Sintering method. Mater. Charact. 111, 21–30 (2016)

C. Waters, M. Salih, S. Ajinola, Porosity comparative analysis of porous copper and OOF Modelling. J. Porous Mater. 22, 989–995 (2015)

J. Ru, B. Kong, Y. Liu, X. Wang, T. Fan, D. Zhang, Microstructure and sound absorption of porous copper prepared by resin curing and foaming method. Mater. Lett. 139, 318–321 (2015)

M. Li, Y. Su, J. Hu, H. Geng, H. Wei, Z. Yang, Y. Zhang, Hydrothermal synthesis of porous copper microspheres towards efficient 4-nitrophenol reduction. Mater. Res. Bull. 83, 329–335 (2016)

H. Nakajima, S.K. Hyun, K. Ohashi, K. Ota, K. Murakami, Fabrication of copper by unidirectional solidification under hydrogen and its properties. Colloid Surf. A 179, 209–214 (2001)

H. Seki, M. Tane, M. Otsuka, H. Nakajima, Effects of pore morphology on fatigue and fracture surface of lotus-type porous copper. J. Mater. Res. 22, 1331–1338 (2007)

S.K. Hyun, K. Murakami, H. Nakajima, Anisotropic mechanical properties of porous copper fabricated by unidirectional solidification. Mater. Sci. Eng. A 299, 241–248 (2001)

Z. Tang, D. Li, Quasi-static axial buckling behavior of NiTi thin-walled cylindrical shells. Thin Wall Struct. 51, 130–138 (2012)

R. Sliž, M.Y. Chang, Reliable and accurate prediction of the experimental buckling of thin-walled cylindrical shell under an axial load. Thin Wall Struct. 49, 409–421 (2011)

X. Luo, J. Xu, J. Zhu, Y. Gao, L. Nie, W. Li, A new method to investigate the energy absorption characteristics of thin-walled metal circular tube using finite element analysis. Thin Wall Struct. 95, 24–30 (2015)

D. Karagiozova, N. Jones, Dynamic effects on buckling and energy absorption of cylindrical shells under axial impact. Thin Wall Struct. 39, 583–610 (2001)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (no.51461029).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jia, J., Jing, Y., Liu, D. et al. Compressive properties of porous Cu reinforced by inserting copper pillars or tubes. J Porous Mater 28, 963–972 (2021). https://doi.org/10.1007/s10934-021-01049-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-021-01049-5