Abstract

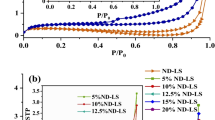

Composite material, tetraethylenepentamine (TEPA) incorporated UiO-66 was prepared by impregnation method to study CO2 capture in a fixed bed reactor, atmospheric pressure. All synthesized adsorbents were characterized using PXRD, N2 adsorption–desorption isotherms, FT-IR, TGA, SEM, and Elemental analysis. Characterization results have revealed that incorporated TEPA was present within pores of UiO-66. CO2 adsorption was higher on TEPA incorporated UiO-66 compared to UiO-66. It was due to the chemical interaction between –NH2 and CO2. High CO2 adsorption capacity 3.70 mmol g−1 was obtained on 30TEPA/UiO-66 at 75 °C, 1 bar. Because of more flexibility and high dispersive nature of TEPA at this temperature. The same CO2 adsorption capacity was obtained in each adsorption cycle without decomposition of the amine on 30TEPA/UiO-66. Avrami adsorption kinetic model has suggested adsorption of CO2 on composite material was chemical adsorption and deactivation model suggested an initial rate of adsorption was higher on TEPA incorporated UiO-66.

Similar content being viewed by others

References

M. Li, K. Huang, J.A. Schott, Z. Wu, S. Dai, Microporous Mesoporous Mater. 249, 34–41 (2017)

D. Aaron, C. Tsouris, Sep. Sci. Technol. 40, 321–348 (2005)

B. Guo, L. Chang, K. Xie, J. Nat. Gas Chem. 15, 223–229 (2006)

S. Hu, C. Li, D. Wan, K. Li, C. Yu, W. Kong, J. Porous Mater. 25, 1691–1696 (2018)

M.R. Delgado, C.O. Arean, Energy 36, 5286–5291 (2011)

F. Gholipour, M. Mofarahi, J. Supercrit. Fluids 111, 47–54 (2016)

N. Chalal, H. Bouhali, H. Hamaizi, B. Lebeau, A. Bengueddach, Microporous Mesoporous Mater. 210, 32–38 (2015)

T.L. Chew, A.L. Ahmad, S. Bhatia, Adv. Colloid Interface Sci. 153, 43–57 (2010)

A. Dhakshinamoorthy, A.M. Asiri, J.R. Herance, H. Garcia, Catal. Today 306, 2–8 (2018)

O.A. Kholdeeva, Catal. Today 278, 22–29 (2016)

B. Li, H. Wang, B. Chen, Chem. Asian J. 9, 1474–1498 (2014)

A. Argoub, R. Ghezini, C. Bachir, B. Boukoussa, A. Khelifa, A. Bengueddach, P.G. Weidler, R. Hamacha, J. Porous Mater. 25, 199–205 (2018)

C. Orellana-Tavra, S.A. Mercado, D. Fairen-Jimenez, Adv. Healthc. Mater. 5, 2261–2270 (2016)

C.-Y. Sun, C. Qin, X.-L. Wang, Z.-M. Su, Expert Opin. Drug Deliv. 10, 89–101 (2013)

E. Redel, Z. Wang, S. Walheim, J. Liu, H. Gliemann, C. Wöll, Appl. Phys. Lett. 103, 091903–091907 (2013)

H.R. Abid, Z.H. Rada, J. Shang, S. Wang, Polyhedron 120, 103–111 (2016)

Z. Bao, S. Alnemrat, L. Yu, I. Vasiliev, Q. Ren, X. Lu, S. Deng, J. Colloid Interface Sci. 357, 504–509 (2011)

J.H. Cavka, S. Jakobsen, U. Olsbye, N. Guillou, C. Lamberti, S. Bordiga, K.P. Lillerud, J. Am. Chem. Soc. 130, 13850–13851 (2008)

Y. Lin, H. Lin, H. Wang, Y. Suo, B. Li, C. Kong, L. Chen, J. Mater. Chem. A 2, 14658–14665 (2014)

F. Martínez, R. Sanz, G. Orcajo, D. Briones, V. Yángüez, Chem. Eng. Sci. 142, 55–61 (2016)

X. Wang, L. Chen, Q. Guo, Chem. Eng. J. 260, 573–581 (2015)

W. Wang, X. Wang, C. Song, X. Wei, J. Ding, J. Xiao, Energy Fuels 27, 1538–1546 (2013)

M.B. Yue, Y. Chun, Y. Cao, X. Dong, J.H. Zhu, Adv. Funct. Mater. 16, 1717–1722 (2006)

M. Anbia, V. Hoseini, J. Nat. Gas Chem. 21, 339–343 (2012)

C. Zlotea, D. Phanon, M. Mazaj, D. Heurtaux, V. Guillerm, C. Serre, P. Horcajada, T. Devic, E. Magnier, F. Cuevas, G. Ferey, P.L. Llewellyn, M. Latroche, Dalton Trans. 40, 4879–4881 (2011)

K. Upendar, T.V. Sagar, G. Raveendra, N. Lingaiah, B.V.S.K. Rao, R.B.N. Prasad, P.S.S. Prasad, RSC Adv. 4, 7142–7147 (2014)

Q. Liu, J. Shi, Q. Wang, M. Tao, Y. He, Y. Shi, Ind. Eng. Chem. Res. 53, 17468–17475 (2014)

S. Øien, D. Wragg, H. Reinsch, S. Svelle, S. Bordiga, C. Lamberti, K.P. Lillerud, Cryst. Growth Des. 14, 5370–5372 (2014)

S. Salehi, M. Anbia, Energy Fuels 31, 5376–5384 (2017)

Y. Lin, Q. Yan, C. Kong, L. Chen, Sci. Rep. 3, 1859 (2013)

H.R. Abid, G.H. Pham, H.M. Ang, M.O. Tade, S. Wang, J. Colloid Interface Sci. 366, 120–124 (2012)

J. Ding, Z. Yang, C. He, X. Tong, Y. Li, X. Niu, H. Zhang, J. Colloid Interface Sci. 497, 126–133 (2017)

X. Wang, H. Li, X.J. Hou, J. Phys. Chem. C 116, 19814–19821 (2012)

X. Su, L. Bromberg, V. Martis, F. Simeon, A. Huq, T.A. Hatton, A.C.S. Appl, Mater. Interfaces 9, 11299–11306 (2017)

L. Guo, J. Yang, G. Hu, X. Hu, H. DaCosta, M. Fan, Nano Energy 25, 1–8 (2016)

L. Guo, X. Hu, G. Hu, J. Chen, Z. Li, W. Dai, H.F.M. Dacosta, M. Fan, Fuel Process. Technol. 138, 663–669 (2015)

G. Zhang, P. Zhao, L. Hao, Y. Xu, J CO2 Util. 24, 22–33 (2018)

X. Wang, Q. Guo, Energy Fuels 30, 3281–3288 (2016)

Y. Liu, J. Shi, J. Chen, Q. Ye, H. Pan, Z. Shao, Y. Shi, Microporous Mesoporous Mater. 134, 16–21 (2010)

Acknowledgements

This work is supported by National Natural Science Foundation of China (NSFC: 51702205) and STU scientific research foundation for Talents (NTF17001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mutyala, S., Yu, YD., Jin, WG. et al. CO2 capture using amine incorporated UiO-66 in atmospheric pressure. J Porous Mater 26, 1831–1838 (2019). https://doi.org/10.1007/s10934-019-00779-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-019-00779-x