Abstract

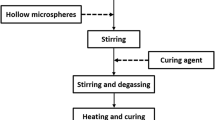

A method for making porous ceramic prepared by adding hollow spheres was developed, and the resulting porous ceramic was named as hollow spheres ceramic. Water soluble epoxy resin was used as a gel former in the gelcasting process of the Al2O3 hollow sphere and Al2O3 powder, the porous ceramic porosity varies from 22.3 to 60.1 %. The influence of amount of Al2O3 hollow sphere and sintering temperature on the microstructure, compressive strength and thermal conductivity were investigated. With an increasing amount of hollow sphere in the matrix, the porosity increases, which leads to decreased bulk density, compressive strength and thermal conductivity. The compressive strength of the porous ceramics has a power law relation with the porosity, and the calculated power law index is 4.5. The equations of the relationship between porosity and thermal conductivity of porous ceramics are proposed. The thermal conductivity of samples with 60.1 % porosity is as low as 2.1 W/m k at room temperature.

Similar content being viewed by others

References

Z.R. Ismagilov, R.A. Shkrabina, N.A. Koryabkina, A.A. Kirchanov, H. Veringa, P. Pex, Porous alumina as a support for catalysts and membranes. Preparation and study. React. Kinet. Catal. Lett. 60, 225–231 (1997)

Y.M. Jo, R.B. Hutchison, J.A. Raper, Characterization of ceramic composite membrane filters for hot gas cleaning. Powder Technol. 91, 55–62 (1997)

P.M. Then, P. Day, The catalytic converter ceramic substrate: an astonishing and enduring invention. Interceram 49, 20–23 (2000)

M.I. Nieto, R. Martinez, M. Leo, C. Baudin, Improvement in the thermal shock resistance of alumina through the addition of submicron-sized aluminium nitride particles. J. Eur. Ceram. Soc. 24, 2293–2301 (2004)

H.R. Ramay, M.Q. Zhang, Preparation of porous hydroxyapatite scaffolds by combination of the gel-casting and polymer sponge methods. Biomaterials 24, 3293–3302 (2003)

O. Lyckfeldt, J.M.F. Ferreira, Processing of porous ceramics by ‘starch consolidation’. J. Eur. Ceram. Soc. 18, 131–140 (1998)

J.L. Yu, J.L. Yang, H.X. Li, X.Q. Xi, Y. Huang, Study on particle-stabilized Si3N4 ceramic foams. Mater. Lett. 65, 1801–1804 (2011)

J.M. Qian, J.P. Wang, G.J. Qiao, Z.H. Jin, Preparation of porous SiC ceramic with a woodlike microstructure by sol-gel and carbothermal reduction processing. J. Eur. Ceram. Soc. 24, 3251–3259 (2004)

H. Ghanem, M. Kormann, H. Gerhard, N. Popovska, Processing of biomorphic porous TiO2 ceramics by chemical vapor infiltration and reaction (CVI-R) technique. J. Eur. Ceram. Soc. 27, 3433–3438 (2007)

D.A. Streitwieser, N. Popovska, H. Gerhard, Optimization of the ceramization process for the production of three-dimensional biomorphic porous SiC ceramics by chemical vapor infiltration (CVI). J. Eur. Ceram. Soc. 26, 2381–2387 (2006)

L. Min, C. Jia, M. Jing, C. Xiao-Hu, W. Bin-Jian, Biomimetic synthesis of porous Si3N4 ceramics. J. Inorg. Mater. 23, 764–769 (2008)

O.P. Chakrabarti, H.S. Maiti, R. Majumdar, Biomimetic synthesis of cellular SiC based ceramics from plant precursor. Bull. Mater. Sci. 27, 467–470 (2004)

Y.T. Zheng, H.B. Li, W. Zhou, X.N. Zhang, G.R. Ye, Combustion synthesis and characteristics of aluminum oxynitride ceramic foams. Ceram. Int. 38, 5139–5144 (2012)

J.F. Qiu, J.T. Li, K.L. Smirnov, Combustion synthesis of high porosity SiC foam with nanosized grains. Ceram. Int. 36, 1901–1904 (2010)

H.X. Peng, Z. Fan, J.R.G. Evans, J.J.C. Busfield, Microstructure of ceramic foams. J. Eur. Ceram. Soc. 20, 807–813 (2000)

J. Luyten, S. Mullens, J. Cooymans, A.M.D. Wilde, I. Thijs, R. Kemps, Different methods to synthesize ceramic foams. J. Eur. Ceram. Soc. 29, 829–832 (2009)

I. Thijs, J. Luyten, S. Mullens, Producing ceramic foams with hollow spheres. J. Am. Ceram. Soc. 87, 170–172 (2004)

U.T. Gonzenbach, A.R. Studart, E. Tervoort, L.J. Gauckler, Ultrastable particle-stabilized foams. Angew. Chem. Int. Ed. 45, 3526–3530 (2006)

U.T. Gonzenbach, A.R. Studart, E. Tervoort, L.J. Gauckler, Stabilization of foams with inorganic colloidal particles. Langmuir 22, 10983–10988 (2006)

U.T. Gonzenbach, A.R. Studart, E. Tervoort, L.J. Gauckler, Macroporous ceramics from particle-stabilized wet foams. J. Am. Ceram. Soc. 90, 16–22 (2007)

Yang JL, Cai K, Xi, XQ, Ge GJ, Huang Y. Method and device for producing hollow microspheres. China Invention Patent 200910131051.7; 2010

J.S. Ha, Effect of atmosphere type on gelcasting behavior of Al2O3 and evaluation of green strength. Ceram. Int. 26, 251–254 (2000)

X.J. Mao, S. Shimai, S.W. Wang, Effects of coarse particles on the gelcasting of ceramic foams. J. Am. Ceram. Soc. 91, 2412–2414 (2008)

X.J. Mao, S. Shimai, S.W. Wang, Gelcasting of alumina foams consolidated by epoxy resin. J. Eur. Ceram. Soc. 28, 217–222 (2008)

X.J. Mao, S. Shimai, S.W. Wang, M.J. Dong, L.L. Jin, Rheological characterization of a gelcasting system based on epoxy resin. Ceram. Int. 35, 415–420 (2009)

M.L. Sun, The application and technics of epoxy resin (Mechanical Industry Press, China, 2002)

X.J. Mao, S.Z. Shimai, S.W. Wang, Gelcasting of alumina foams consolidated by epoxy resin. J. Eur. Ceram. Soc. 28, 217–222 (2008)

Z. Zivcova, E. Gregorova, P. Willi, D.S. Smith, A. Michot, C. Poulier, Thermal conductivity of porous alumina ceramics prepared using starch as a pore-forming agent. J. Eur. Ceram. Soc. 29, 347–353 (2009)

Acknowledgments

This research work is supported by the National Natural Science Fund (project number: 51172120) and special support for the innovation work of Ministry of Science and Technology (project number: 2011IM030800) and Shanxi Province Science and Technology Major Project of China (project number: 20111101015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Su, Z., Xi, X., Hu, Y. et al. A new Al2O3 porous ceramic prepared by addition of hollow spheres. J Porous Mater 21, 601–609 (2014). https://doi.org/10.1007/s10934-014-9806-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-014-9806-7