Abstract

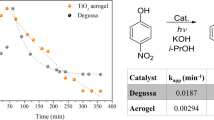

Silica–titania composite aerogels were synthesized via ambient pressure drying by using water glass and titanium tetrachloride as raw materials. The influences of heat-treatment at different temperature with different heating rate on the microstructure and properties of the composite aerogels were investigated by differential thermal analyzer, Fourier transform infrared spectrometer, X-ray diffraction, nitrogen adsorption–desorption, scanning electron microscope and transmission electron microscope analysis. The results indicate that the silica–titania composite aerogels heat-treated at 250 °C exhibited highest specific surface area, pore volume and average pore diameter. When the heat-treatment temperature was higher than 450 °C, the –CH3 groups on the surface of silica–titania composite aerogels would transform into –OH groups gradually, and in the meantime, the composite aerogels network structure would be destroyed gradually and the crystallinity of TiO2 would be improved with the increase of heat-treatment temperature. Particularly, heat-treatment at temperatures above 750 °C would cause serious damage to the network structure of the composite aerogels. The adsorption/photocatalytic activity experiments showed that the composite aerogels heat-treated at 550 °C exhibit highest darkroom adsorption efficiency, and the 650 °C-heat-treated samples exhibited highest efficiency for removing the Rhodamine B from water.

Similar content being viewed by others

References

Y. Duan, S.C. Jana, A.M. Reinsel, B. Lama, M.P. Espe, Langmuir 28, 15362 (2012)

H. Satha, K. Atamnia, F. Despetis, J. Biomater. Nanotechnol. 4, 17 (2013)

I.K. Jung, J.L. Gurav, T.J. Ha, S.G. Choi, S. Baek, H.H. Park, Ceram. Int. 38, 105 (2012)

J.L. Gurav, I. Jung, J. Nanomater. 2010, 23 (2010)

G.M. Gao, X.C. Xu, H.F. Zou, G.J. Ji, S.C. Gan, Powder Technol. 202, 137 (2010)

S.L. Lee, H. Nur, S.C. Wei, Appl. Mech. Mater. 110, 457 (2012)

U.K. Nizar, J. Efendi, L. Yuliati, D. Gustiono, H. Nur, Chem. Eng. J. 222, 23 (2013)

M.A. Reiche, E. Ortelli, A. Baiker, Appl. Catal. B Environ. 23, 187 (1999)

P. Klankaw, C. Chawengkijwanich, N. Grisdanurak, S. Chiarakorn, Superlattices Microstruct. 51, 343 (2012)

M. Liu, L. Gan, Y. Pang, Z. Xu, Z. Hao, Colloids. Surf. A Physicochem. Eng. Asp. 317, 490 (2008)

S.V. Ingale, P.U. Sastry, P.B. Wagh, A.K. Tripathi, R. Rao, R. Tewari, S.C. Gupta, Mater. Chem. Phy. 135, 497 (2012)

G.N. Shao, A. Hilonga, S.J. Jeon, J.E. Lee, G. Elineema, D.V. Quang, Powder Technol. 233, 123 (2013)

P.R. Aravind, P. Shajesh, P. Mukundan, K.G.K. Warrier, J. Sol-Gel Sci. Technol. 52, 328 (2009)

J. Liu, X. Leng, F. Shi, J. Ceram. Soc. 38, 2296 (2010). (in Chinese)

S. Cao, K.L. Yeung, P.L. Yue, Appl. Catal. B Environ. 68, 99 (2006)

X. Leng, J. Liu, F. Shi, J. Inorg. Chem. 25, 1791 (2009). (in Chinese)

F. Shi, L. Wang, J. Liu, M. Zeng, J. Mater. Sci. Technol. 23, 402 (2007)

J. Lin, H. Chen, T. Fei, Appl. Surf. Sci. 273, 776 (2013)

C. Huang, Z. Wei, L. Zhang, J. Porous. Mater. 20, 1017 (2013)

P.V. Messina, P.C. Schulz, J. Colloid. Interface Sci. 299, 305 (2006)

L. Melonea, L. Altomare, I. Alfieri, A. Lorenz, J. Photochem. Photobiol. A Chem. 261, 53 (2013)

Acknowledgments

We are grateful for the financial support of the National Natural Science Foundation of China (No. 51278074), the Project of Dalian Science & Technology Foundation (2007J23JH014), and Dalian City Construction Science & Technology Project (20111228).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Liu, J., Shi, F. et al. Influences of heat-treatment on the microstructure and properties of silica–titania composite aerogels. J Porous Mater 21, 293–301 (2014). https://doi.org/10.1007/s10934-013-9774-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-013-9774-3