Abstract

The effect of the support pore size on the membrane morphology was investigated for zeolite silicalite-1 membranes synthesized by pore plugging method on supports with zirconium oxide and/or titanium oxide active layer. Parameters including surface coverage, zeolite layer thickness, crystal size and shape, zeolite penetration depth were used to quantify the membrane morphology. Five supports with different pore sizes for their active layer in the range of 0.14–1.4 μm were investigated. The X-ray diffraction (XRD) analysis showed a typical silicalite-1 zeolite structure with a high internal crystalline order grown inside the pores as well as on top of all supports. The XRD results also showed that the silicalite-1 crystals in the synthesized membranes are not randomly oriented. The crystallographic preferred orientation (CPO) analysis revealed that the degree of orientation toward either the a-axis or b-axis perpendicular to the support surface, increased by decreasing the pore size of the support. The 0.45 μm support had the most preferably oriented zeolite layer for access of molecules entering into the membrane structure with the highest number of crystals oriented with the b-axis (the one with straight channels) perpendicular to the support surface. The scanning electron micrographs (SEM) analysis of the membranes revealed a dense and continuous surface morphology with the highest crystal size of silicalite-1 around 1.5 μm on the surface of the support with the 0.45 μm pore size. SEM micrographs also showed a continuous layer grown over four supports out of five supports with different pore sizes that were investigated, with no layer observed on the 1.4 μm pore size support. The average thickness of the zeolite layer was in the range of 0.7–1.4 μm, depending on the pore size of the support. The supports with 0.2 and 0.45 μm pore sizes had the most uniform zeolite layer thickness while the support with 0.8 μm pore size active layer had the least uniform zeolite layer thickness. The electron diffraction spectrometer (EDS) analysis confirmed the formation of pure silicalite-1 layer at the surface as well as inside the pores of all supports. The highest silicalite-1 crystal penetration was for the supports with 0.45 and 1.4 μm pore sizes. Single gas permeation experiments with He and N2 gases at 293 K illustrated that regardless of the pore size of the support, the He and N2 permeances were constant despite the change of the pressure across the membranes. The highest permeances were observed for the membrane prepared using the 0.45 μm pore size support, while the lowest permeances were for the membrane prepared using the 1.4 μm pore size support. These results confirmed the selective properties of the prepared membranes. No matter what is the pore size of the support or the feed pressure, N2 permeances were around three times higher than those for He.

Similar content being viewed by others

Abbreviations

- BET:

-

Brunauer–Emmett–Teller

- BJH:

-

Barrett–Joyner–Halenda data interpretation method

- CP:

-

Cross polarization

- CPO:

-

Crystallographic preferred orientation

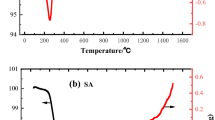

- DSC:

-

Differential scanning calorimeter

- DTGA:

-

Differential thermal gravimetric analysis

- EDS:

-

Electron diffraction spectrometer

- IZA:

-

International Zeolite Association

- MAS:

-

Magic angle spinning

- NMR:

-

Nuclear magnetic resonance

- SEM:

-

Scanning electron microscope

- TAOH:

-

Tetrapropylammonium hydroxide

- TGA:

-

Thermal gravimetric analysis

- XRD:

-

X-ray diffraction

References

A. Tavolaro, E. Drioli, Zeolite membranes. Adv. Mater. 11, 975–996 (1999)

M. Kazemimoghadam, T. Mohammadi, Synthesis of MFI zeolite membranes for water desalination. Desalination 206, 547–553 (2007)

W. Yuan, Y.S. Lin, W. Yang, Molecular sieving MFI-type zeolite membranes for pervaporation separation. J. Am. Chem. Soc. 126, 4776–4777 (2004)

F. Jareman, C. Andersson, J. Hedlund, The influence of the calcination rate on silicalite-1 membranes. Microporous Mesoporous Mater. 79, 1–5 (2005)

H.H. Funke, M.G. Kovalchick, J.L. Falconer, R.D. Noble, Separation of hydrocarbon isomer vapors with silicalite zeolite membranes. Ind. Eng. Chem. Res. 35, 1575 (1996)

A. Javaid, Membranes for solubility-based gas separation applications. J. Chem. Eng. 112, 219–226 (2005)

B.M. Lok, T.R. Cannan, C.A. Messina, The role of organic molecules in molecular sieve synthesis. Zeolites 3, 282–291 (1983)

S.P. Davis, E.V.R. Borgstedt, S.L. Suib, Growth of zeolite crystallites and coatings on metal surfaces. Chem. Mater. 2, 712–719 (1990)

T. Matsufuji, N. Nishiyama, M. Matsukata, K. Ueyama, Separation of butane and xylene isomers with MFI-type zeolite membranes synthesized by a vapour-phase transport method. J. Membr. Sci. 178, 25–34 (2000)

A. Gouzinis, M. Tsapatsis, On the preferred orientation and microstructural manipulation of molecular sieve films prepared by secondary growth. Chem. Mater. 10, 2497–2504 (1998)

S. Miachon, E. Landrivon, M. Aouine, Y. Sun, I. Kumakiri, Y. Li, O. Pachtova Prokopova, N. Guilhaume, A. Giroir-Fendler, H. Mozzanega, J.-A. Dalmon, Nanocomposite MFI-alumina membranes via pore-plugging synthesis: preparation and morphological characterization. J. Membr. Sci. 281, 228–238 (2006)

S. Miachon, P. Ciavarella, L. van Dyk, I. Kumakiri, K. Fiaty, Y. Schuurman, J.-A. Dalmon, Nanocomposite MFI-alumina membranes via pore-plugging synthesis: specific transport and separation properties. J. Membr. Sci. 298, 71–79 (2007)

C. Kong, J. Lu, J. Yang, J. Wang, Preparation of silicalite-1 membranes on stainless steel supports by a two-stage varying-temperature in situ synthesis. J. Membr. Sci. 285, 258–264 (2006)

E. Bourgeat-Lami, P. Massiani, F.D. Renzo, P. Espiau, F. Fajula, Th.D. Courieres, Study of the state of aluminium in zeolite-β. Appl. Catal. 72, 139–152 (1991)

N.Y. Chen, Hydrophobic properties of zeolites. J. Phys. Chem. 80, 60–64 (1978)

J. Caro, M. Noack, Zeolite membranes—recent development and progress. Microporous Mesoporous Mater. 115, 215–233 (2008)

G.E. Romanos, Th.A. Steriotis, E.S. Kikkinides, N.K. Kanellopoulos, V. Kasselouri, J.D.F. Ramsay, P. Langlois, S. Kallus, Innovative methods for preparation and testing of Al2O3 supported silicalite-1 membranes. J. Eur. Ceram. Soc. 21, 119–126 (2001)

E. Landrivon, S. Miachon, I. Kumakiri, M. Matsukata, J.-A. Dalmon, MFI-alumina composite membrane. Influence of the support porous structure on the separative performance. Fuel Chem. Div. Prepr. 48, 394–395 (2003)

M. Pan, Y.S. Lin, Template-free secondary growth synthesis of MFI type zeolite membranes. Microporous Mesoporous Mater. 43, 319–327 (2001)

S. Storck, H. Bretinger, W.F. Maier, Characterization of micro- and mesoporous solids by physisorption methods and pore-size analysis. Appl. Catal. A 174, 137–146 (1998)

E.P. Barrett, L.G. Joyner, P.P. Halenda, The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J. Am. Chem. Soc. 73, 373–380 (1951)

M. Tawalbeh, B. Kruczek, F.H. Tezel, S. Letaief, C. Detellier, Separation of CO2 and N2 gases using a novel zeolite membrane. Sep. Sci. Tech. 47, 1606–1616 (2012)

G. Defontaine, A. Barichard, S. Letaief, C. Feng, T. Matsuura, C. Detellier, Nanoporous polymer—clay hybrid membranes for gas separation. J. Coll. Interf. Sci. 343, 622–627 (2010)

R. Ravishankar, C. Kirschhock, B.J. Schoeman, P. Vanoppen, P.J. Grobet, S. Storck, W.F. Maier, J.A. Martens, F.C. De Schryver, P.A. Jacobs, Physicochemical characterization of silicalite-1 nanophase material. J. Phys. Chem. B 102, 2633–2639 (1998)

A. Manna, B.D. Kulkarni, R.K. Ahedi, A. Bhaumik, A.N. Kotasthane, Synthesis of silicalite-1 in bicontinuous microemulsion containing AOT. J. Coll. Interf. Sci. 213, 405–411 (1999)

J.M. Chezeau, L. Delmotte, J.L. Guth, Z. Gabelica, Influence of synthesis conditions and post synthesis treatments on the nature and quantity of structural defects in highly siliceous MFI zeolites: a high-resolution solid-state 29Si n.m.r. study. Zeolites 11, 598–606 (1991)

X. Lin, H. Kita, K. Okamoto, Silicalite membrane preparation, characterization, and separation performance. Ind. Eng. Chem. Res. 40, 4069–4078 (2001)

J. Dong, J. Zou, Y. Long, Synthesis and characterization of colloidal TBA-silicalite-2. Microporous Mesoporous Mater. 57, 9–19 (2003)

M. Soulard, S. Bilger, H. Kessler, J.L. Guth, Thermoanalytical characterization of MFI-type zeolites prepared either in the presence of OH− or of F− ions. Zeolites 7, 463–470 (1987)

L.M. Parker, D.M. Bibby, J.E. Patterson, Thermal decomposition of ZSM-5 and silicalite precursors. Zeolites 4, 168–174 (1984)

M.R. Othman, S.C. Tan, S. Bhatia, Separability of carbon dioxide from methane using MFI zeolite–silica film deposited on gamma-alumina support. Microporous Mesoporous Mater. 121, 138–144 (2009)

S.P. Naik, A.S.T. Chiang, R.W. Thompson, F.C. Huang, Formation of silicalite-1 hollow spheres by the self-assembly of nanocrystals. Chem. Mater. 15, 787–792 (2003)

Y. Ma, J. Guan, S. Wu, J. Liu, Q. Kan, W. Zhang, Synthesis and characterization of belt-like silicalite-1 nanocrystals with mesoporous structure. Mater. Lett. 64, 2523–2525 (2010)

J. Caro, M. Noack, P. Kolsch, Zeolite membranes: from the laboratory scale to technical applications. Adsorption 11, 215–227 (2005)

M.C. Lovallo, M. Tsapatsis, Preferentially oriented submicron silicalite membranes. AIChE J. 42, 3020–3029 (1996)

J.P. Verduijn, A.J. Bons, M.H. Anthonis, L.H. Czarnetzki, Int. Patent Appl. PCT WO 96/01683

J. Hedlund, Control of the preferred orientation in MFI films synthesized by seeding. J. Porous Mater. 7, 455–464 (2000)

J. Heldund, S. Mintova, J. Sterte, Controlling the preferred orientation in silicalite-1 films synthesized by seeding. Microporous Mesoporous Mater. 28, 185–194 (1999)

M.A. Ulla, R. Mallada, J. Coronas, L. Gutierrez, E. Miro, J. Santamaria, Synthesis and characterization of ZSM-5 coatings onto cordierite honeycomb supports. Appl. Catal. A 253, 257–269 (2003)

L. Tosheva, B. Mihailova, V. Valtchev, J. Sterte, Silicalite-1 macrostructures—preparation and structural features. Microporous Mesoporous Mater. 39, 91–101 (2000)

I. Diaz, E. Kokkoli, O. Terasaki, M. Tsapatsis, Surface structure of zeolite (MFI) crystals. Chem. Mater. 16, 5226–5232 (2004)

A. Larbot, J.-P. Fabre, C. Guizard, L. Cot, J. Gillot, New inorganic ultrafiltration membranes: titania and zirconia membranes. J. Am. Ceram. Soc. 72, 257–261 (1989)

R. Gopalan, C.-H. Chang, Y.S. Lin, Thermal stability improvement on pore and phase structure of sol-gel derived zirconia. J. Mater. Sci. 30, 3075–3081 (1995)

M. Kanezashi, J. O’Brien, Y.S. Lin, Thermal stability improvement of MFI-type zeolite membranes with doped zirconia intermediate layer. Microporous Mesoporous Mater. 103, 302–308 (2007)

J. Motuzas, R. Mikutaviciute, E. Gerardin, A. Julbe, Controlled growth of thin and uniform TS-1 membranes by MW-assisted heating. Microporous Mesoporous Mater. 128, 136–143 (2010)

Y. Takata, T. Tsuru, T. Yoshioka, M. Asaeda, Gas permeation properties of MFI zeolite membranes prepared by the secondary growth of colloidal silicalite and application to the methylation of toluene. Microporous Mesoporous Mater. 54, 257–268 (2002)

F. Jareman, J. Hedlund, Permeation of H2, N2, He, and SF6 in real MFI membranes. Microporous Mesoporous Mater. 83, 326–332 (2005)

K. Aoki, V.A. Tuan, J.L. Falconer, R.D. Noble, Gas permeation properties of ion-exchanged ZSM-5 zeolite membranes. Microporous Mesoporous Mater. 39, 485–492 (2000)

W.J.W. Bakker, L.J.P. Broeke, F. Kapteijn, J. Moulijn, Temperature dependence of one-component permeation through a silicalite-I membrane. AIChE J. 43, 2203–2214 (1997)

Z. Lai, M. Tsapatsis, Gas and organic vapor permeation through b-oriented MFI membranes. Ind. Eng. Chem. Res. 43, 3000–3007 (2004)

Acknowledgments

The authors acknowledge the financial support received from Natural Science and Engineering Research Council (NSERC) of Canada and from the University of Ottawa. The Canada Foundation for Innovation and the Ontario Research Fund are gratefully acknowledged for infrastructure grants obtained by the Center for Catalysis Research and Innovation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tawalbeh, M., Tezel, F.H., Kruczek, B. et al. Synthesis and characterization of silicalite-1 membrane prepared on a novel support by the pore plugging method. J Porous Mater 20, 1407–1421 (2013). https://doi.org/10.1007/s10934-013-9726-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-013-9726-y